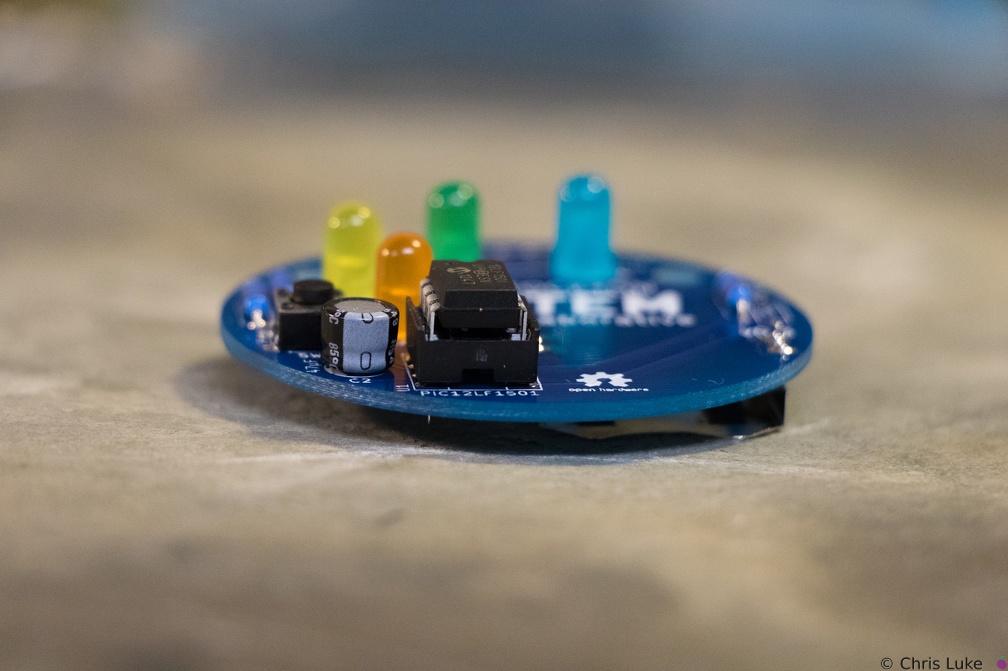

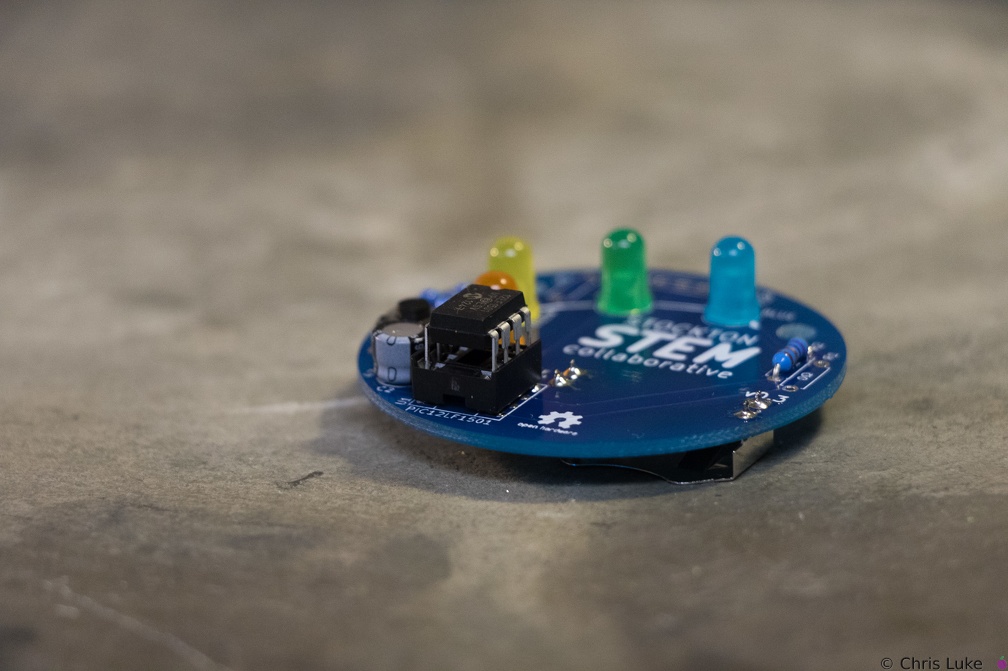

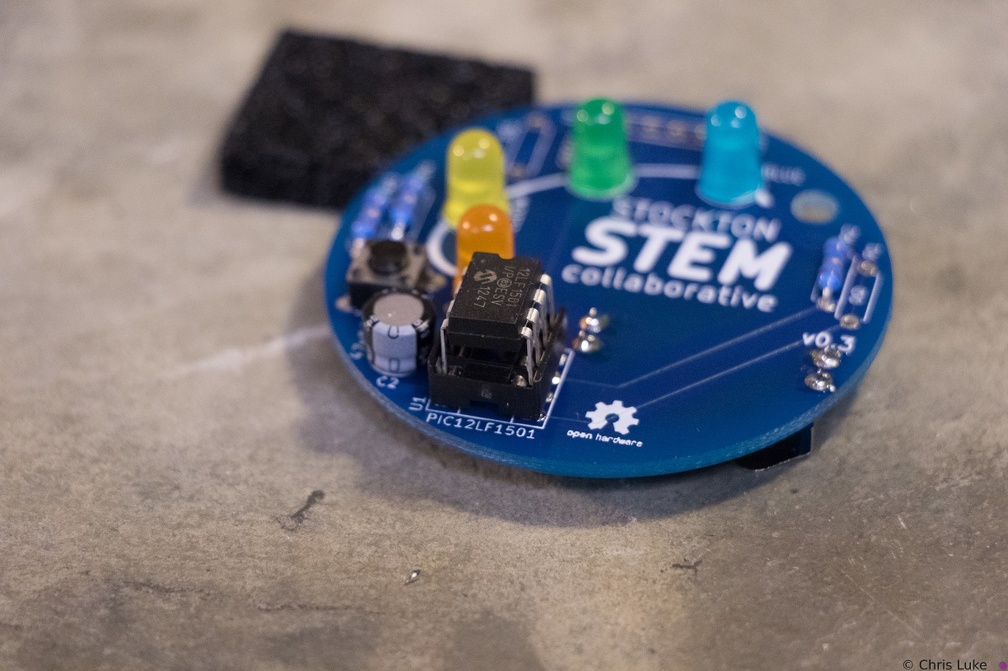

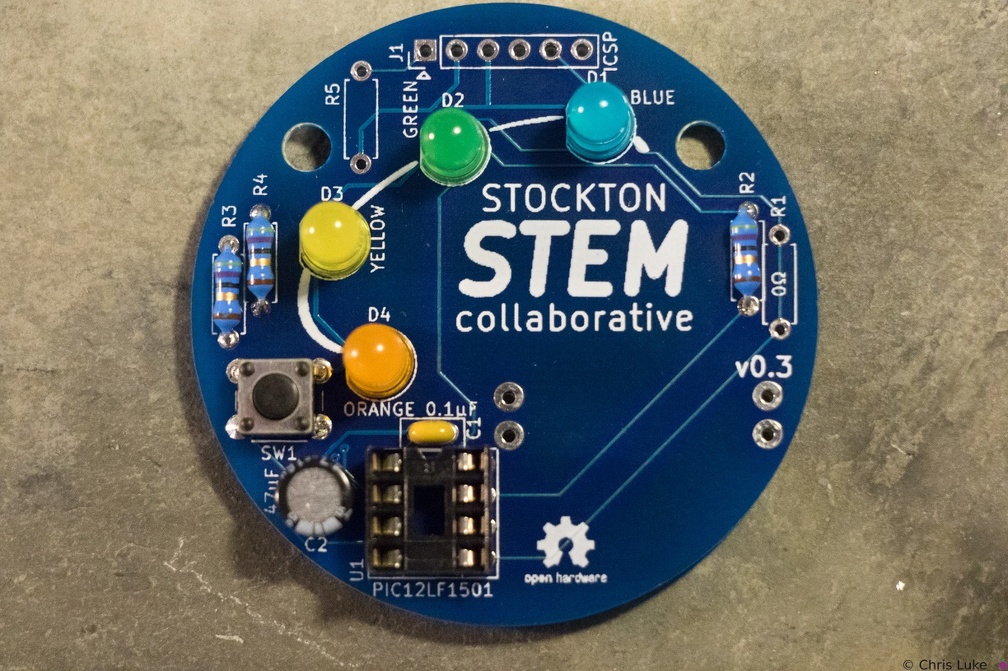

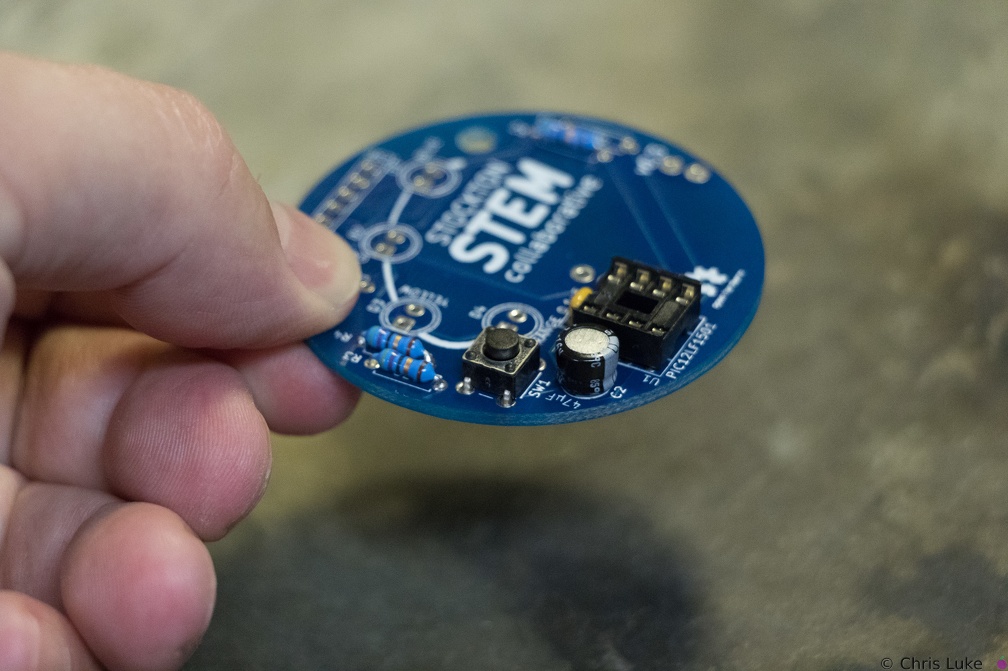

Stockton STEM Badge completed

Stockton STEM Badge completed

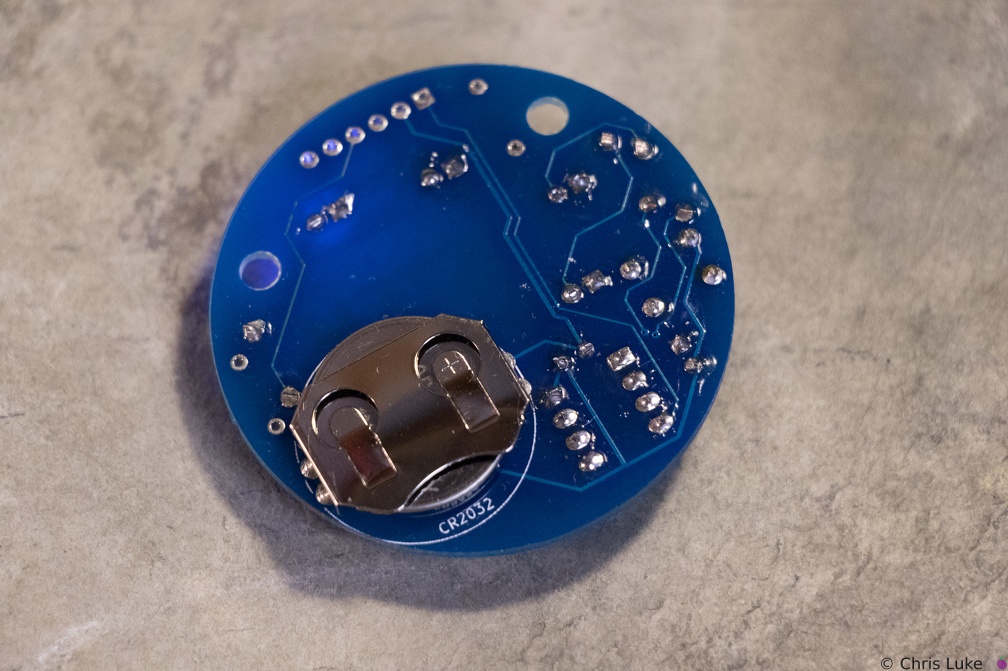

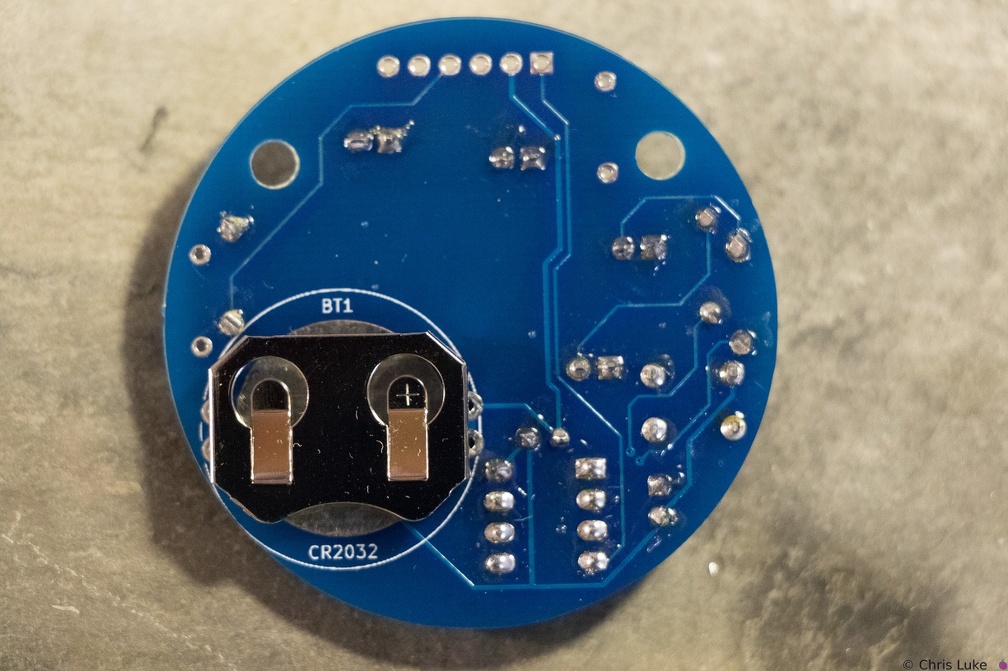

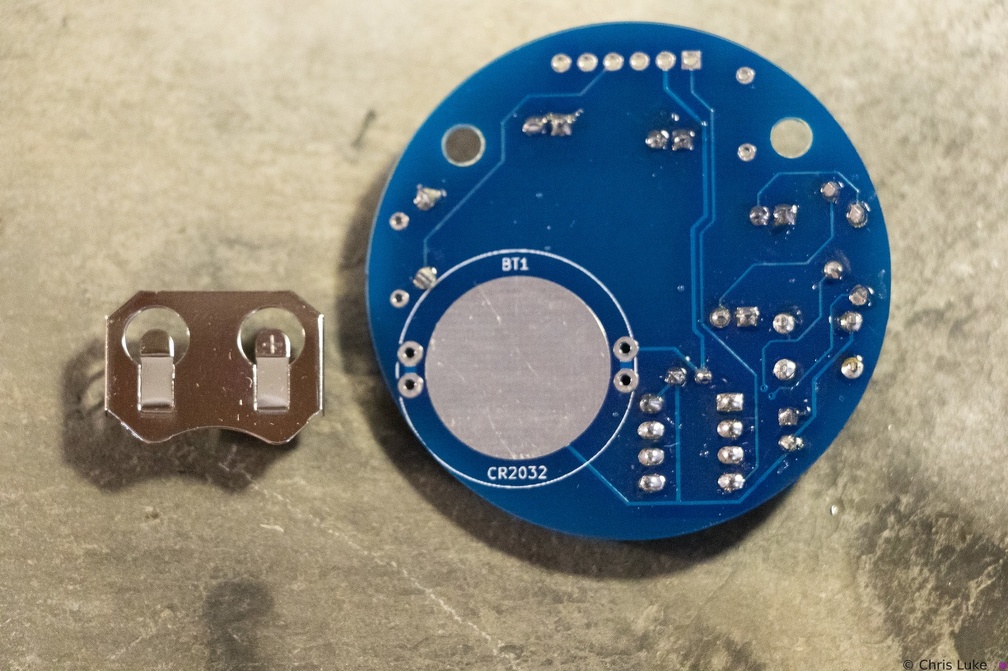

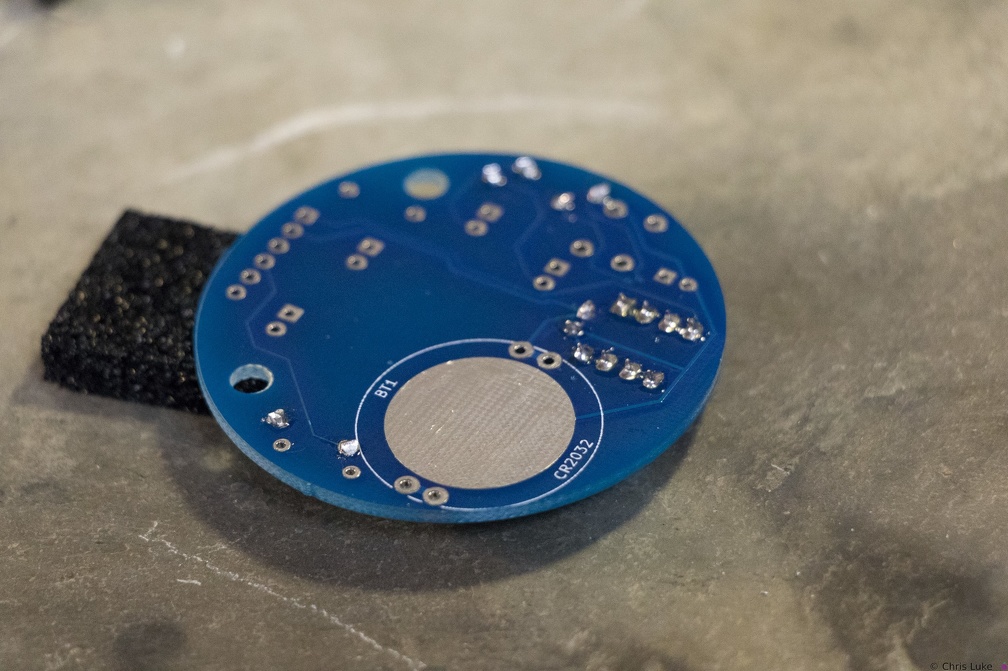

Press the button to start the lights! Stockton STEM Badge battery

Stockton STEM Badge battery

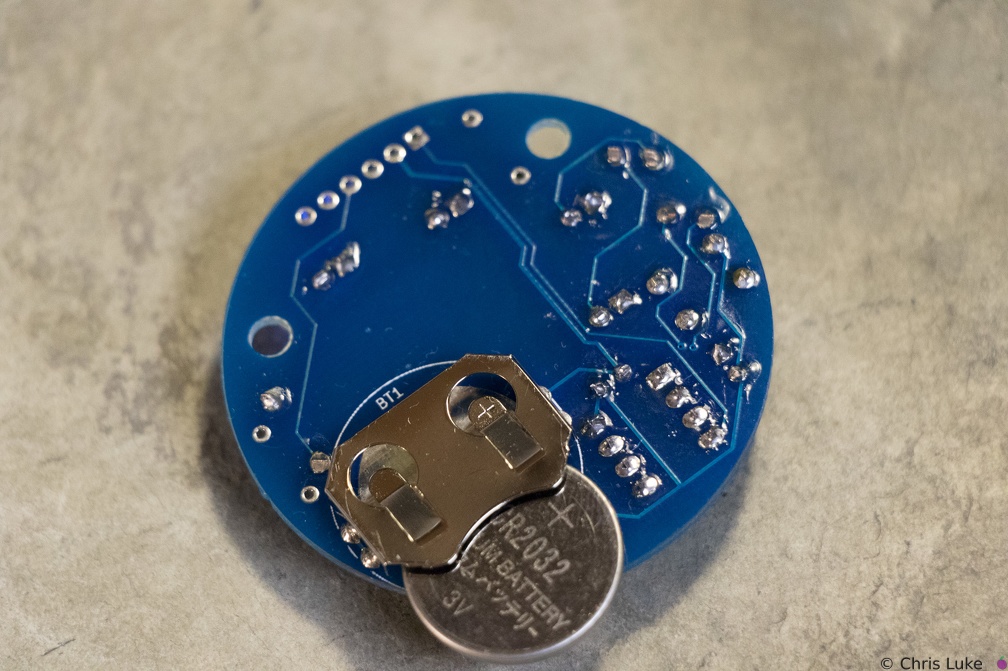

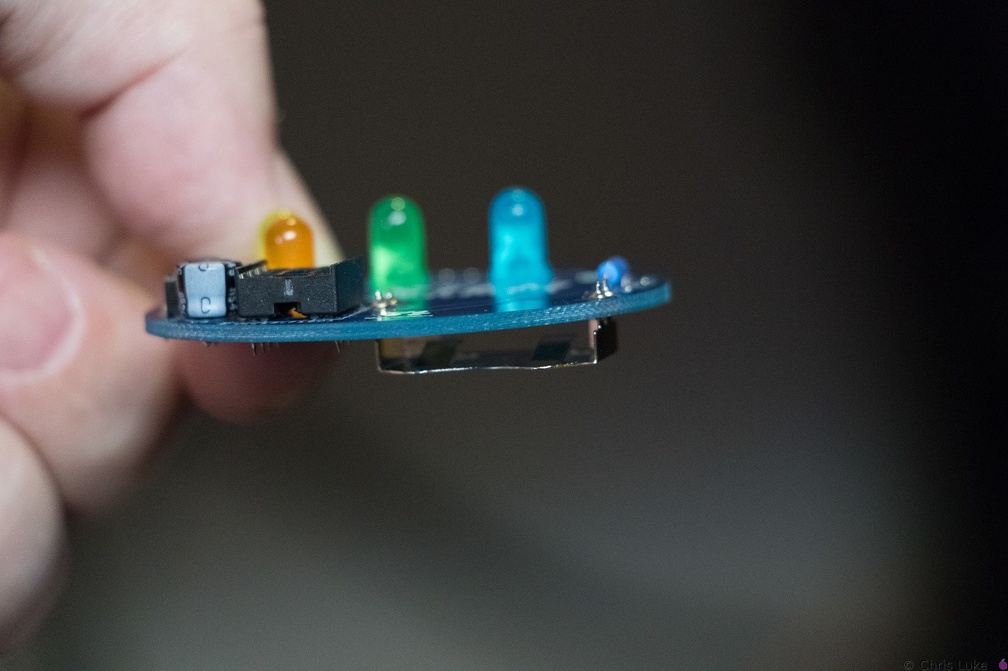

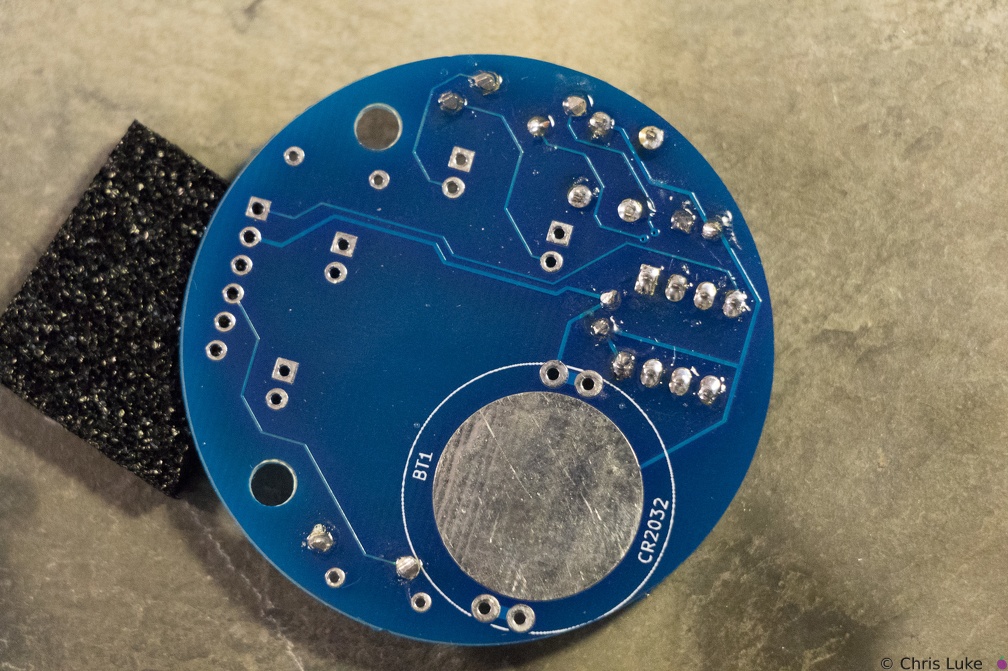

The battery should sit snugly under the holder. Stockton STEM Badge battery

Stockton STEM Badge battery

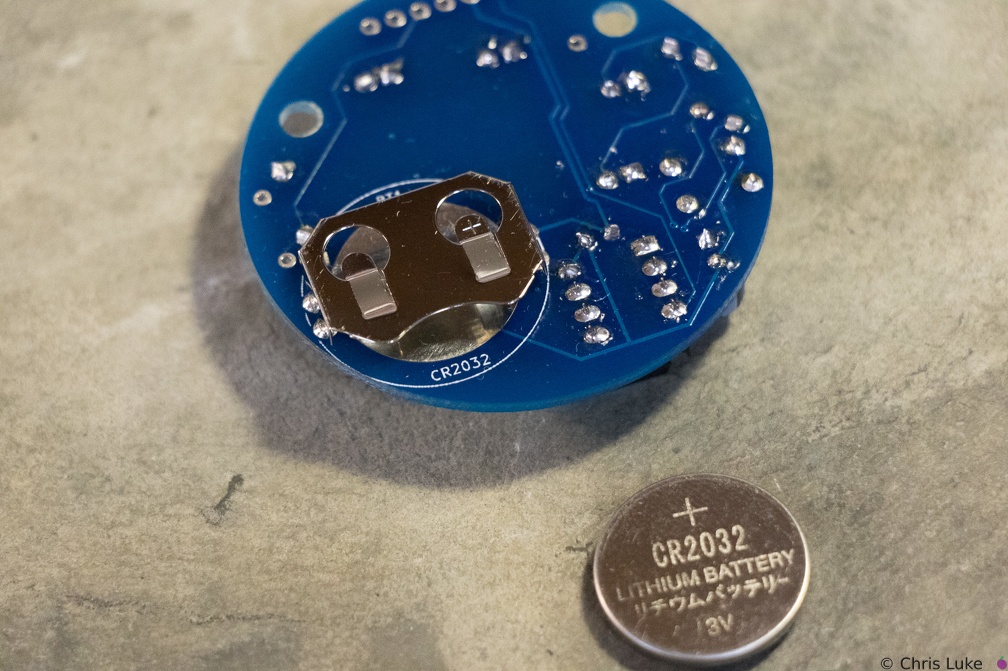

Note the orientation of the battery. The "+" side contacts the battery holder. Stockton STEM Badge battery

Stockton STEM Badge battery

The battery is a typical CR2032 button cell. Notice which side the "+" is on. Stockton STEM Badge IC

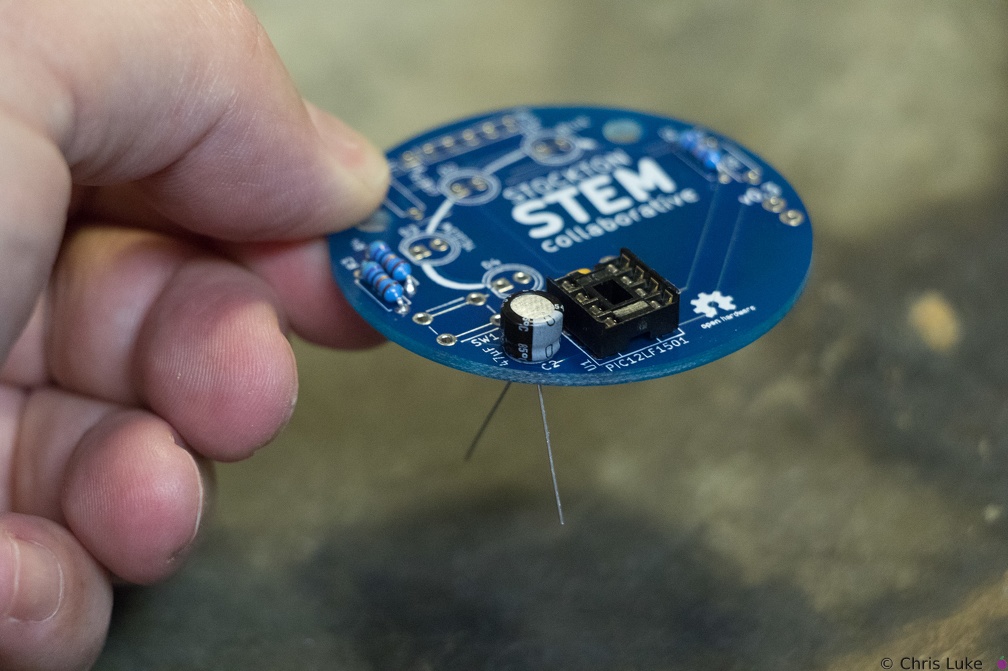

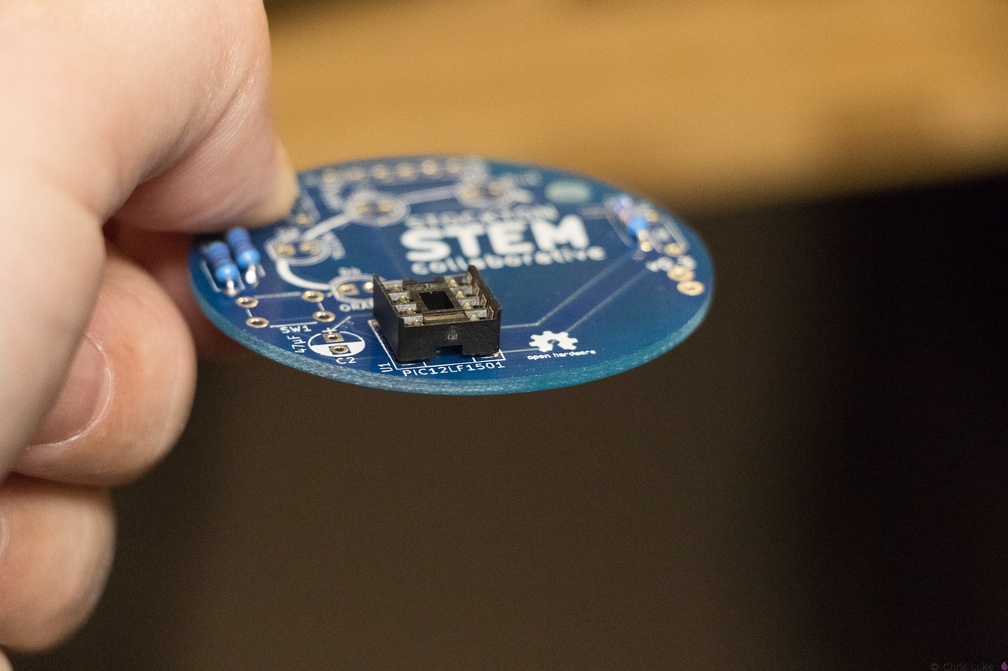

Stockton STEM Badge IC

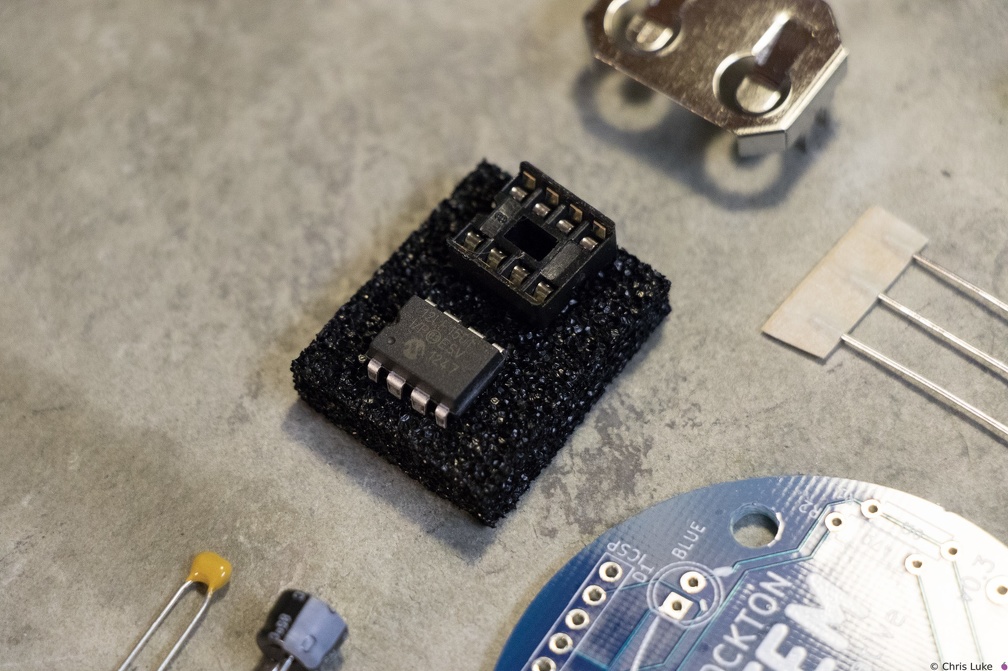

Once pushed all the way in, the IC may sit above the socket, but it will be parallel to it. Stockton STEM Badge IC

Stockton STEM Badge IC

Make sure the IC is correctly aligned before pushing it in. Stockton STEM Badge IC

Stockton STEM Badge IC

When inserting the IC, firm but controlled pressure is needed to avoid bending the pins. Stockton STEM Badge IC

Stockton STEM Badge IC

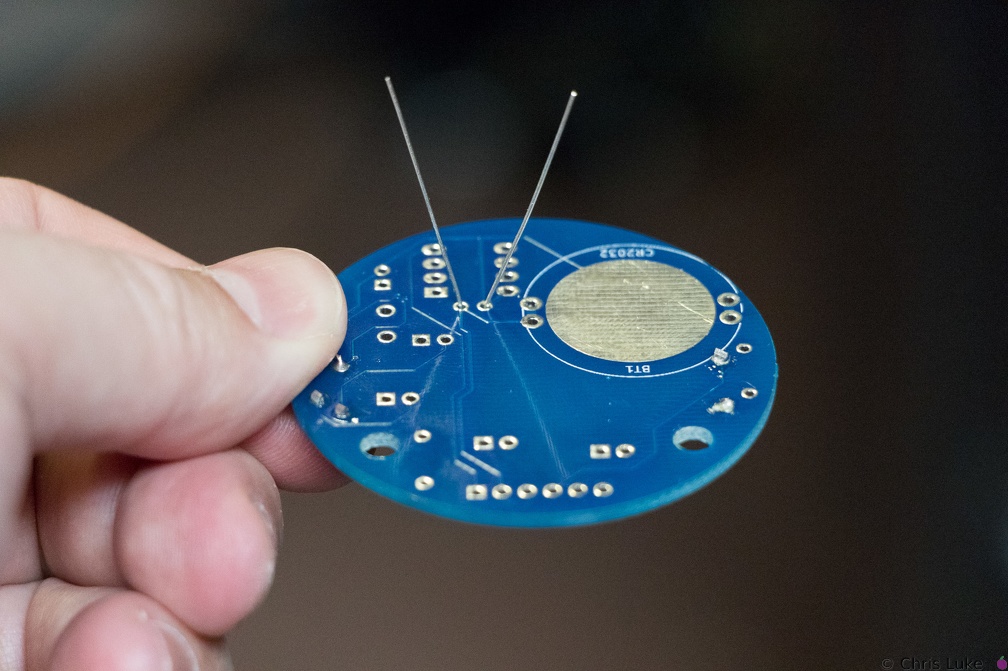

The IC pins need to be straight and line up with their receptacles in the socket. Stockton STEM Badge battery

Stockton STEM Badge battery

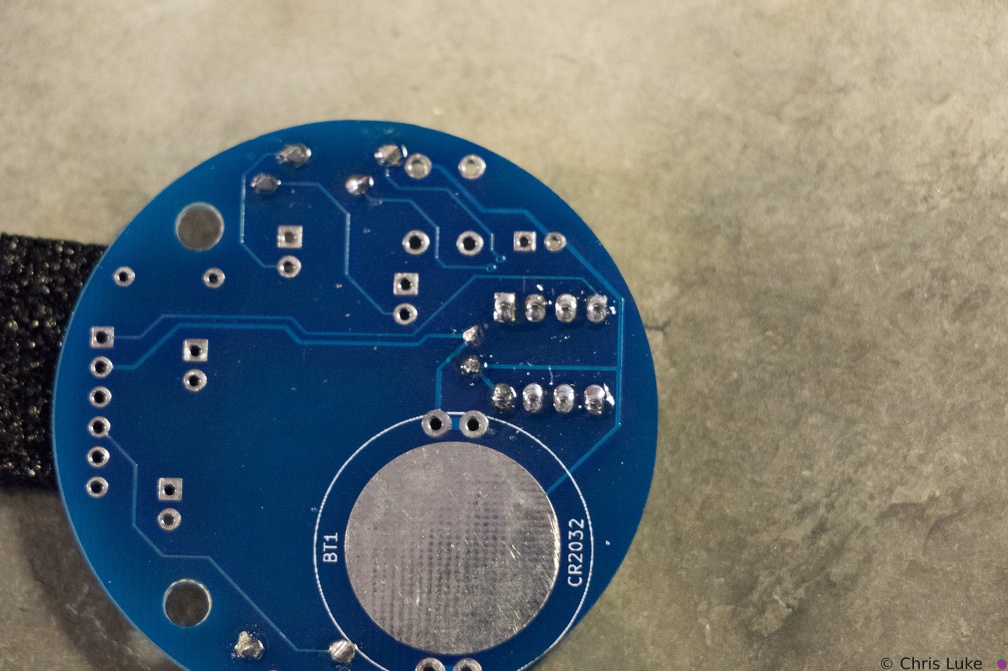

It is possible for the holder to become hot during soldering; be careful when handling immediately after soldering. Stockton STEM Badge battery

Stockton STEM Badge battery

Note the orientation of the holder; reversing it will make it difficult to insert the battery later. Stockton STEM Badge battery

Stockton STEM Badge battery

The battery holder is a simple metal cage that solders to the underside of the board. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

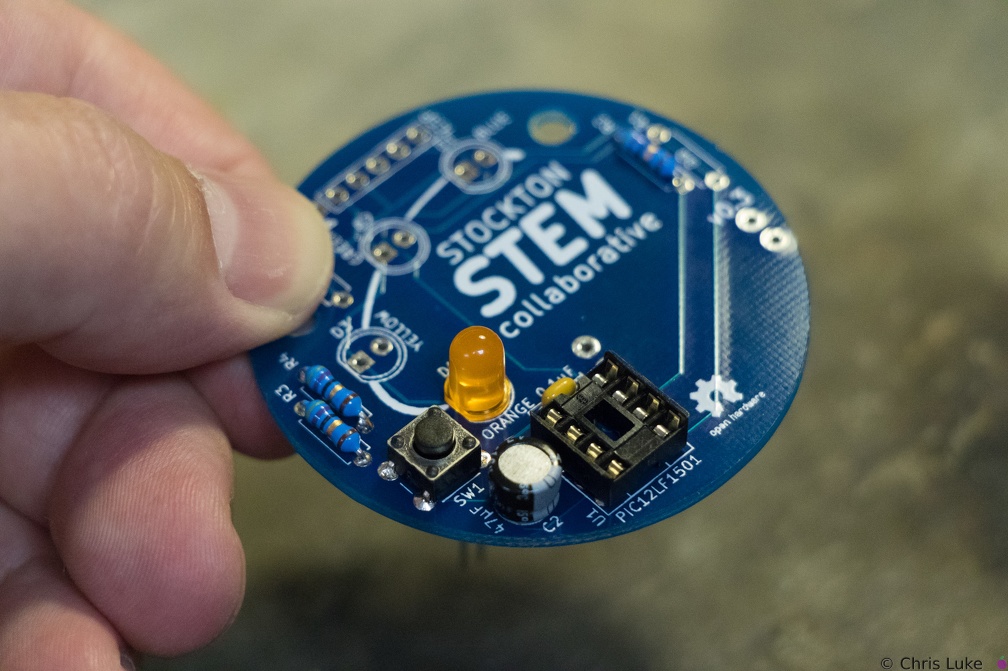

All the LEDs have been soldered. Notice that they all have the same orientation; the flat edge is to the left. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

The case of an LED can crack if the legs are bent too close to it; even after placing the LED on the board, only bend the legs slightly to hold it in place. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

While all components can be destroyed with an excess of heat during soldering, LEDs are especially susceptible to this. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

The footprint for the LEDs also shows a flat edge; orientation of the LEDs needs to match that of the board. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

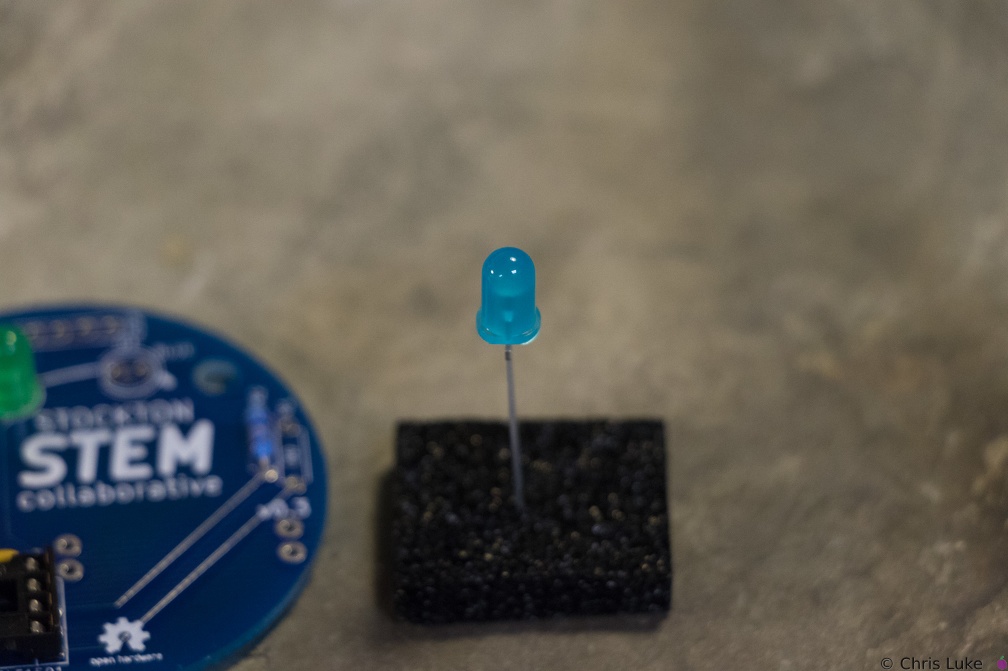

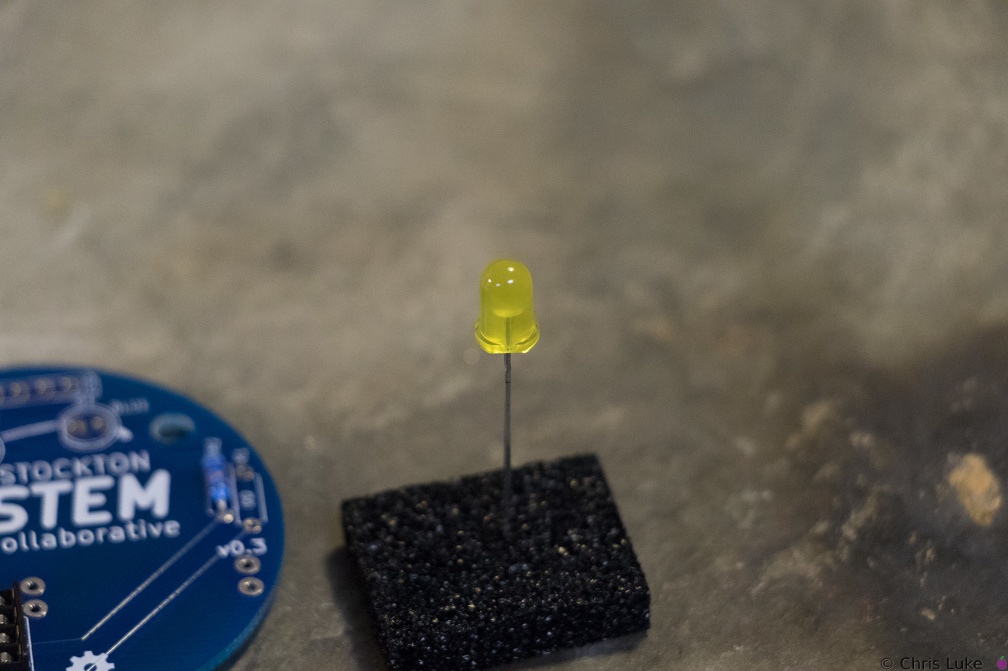

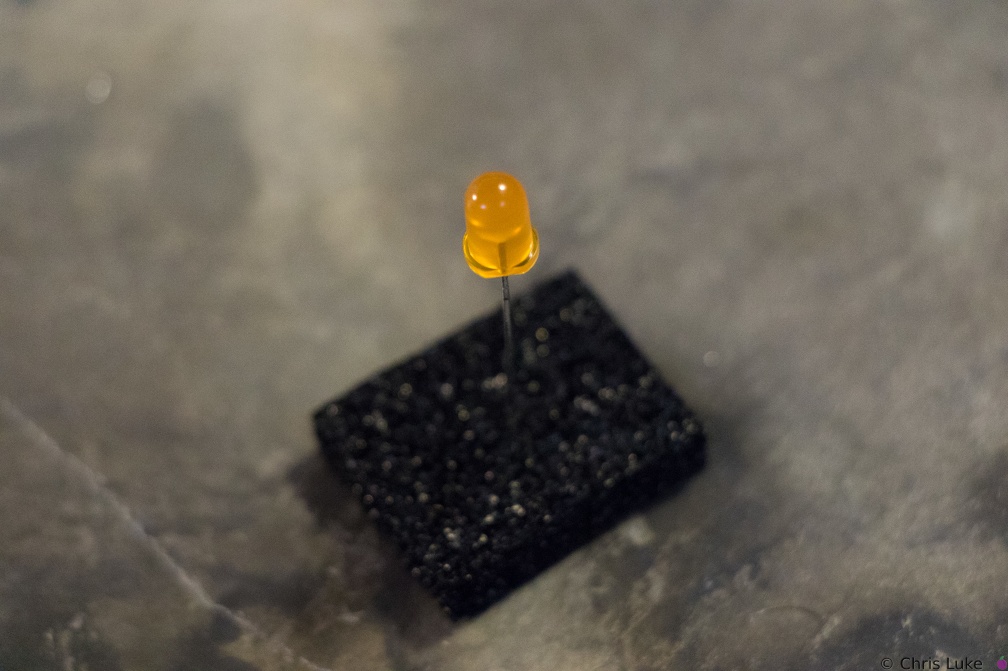

LEDs have a flat edge on one side of their case. Stockton STEM Badge button

Stockton STEM Badge button

As with the IC socket, soldering one leg first and verifying component alignment will help prevent easy mistakes. Stockton STEM Badge button

Stockton STEM Badge button

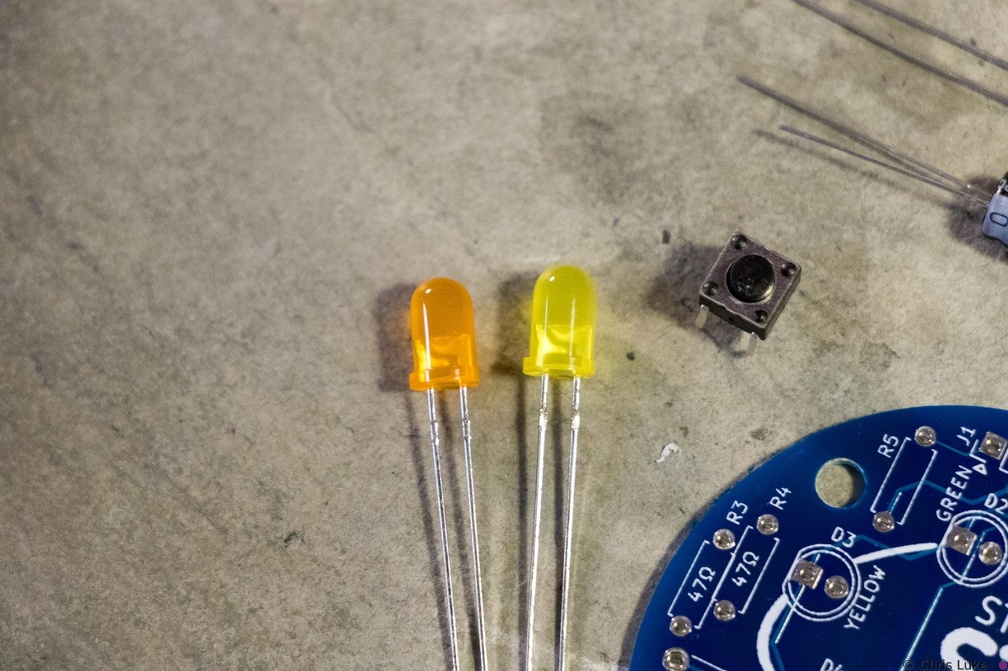

The push-button switch will fit two ways. Orientation does not matter. Stockton STEM Badge electrolytic capacitor

Stockton STEM Badge electrolytic capacitor

Orientation of this capacitor is important. There is a "+" symbol in the footprint of the component printed on the board; the "-" of the capacitor should be on the opposite side. Stockton STEM Badge electrolytic capacitor

Stockton STEM Badge electrolytic capacitor

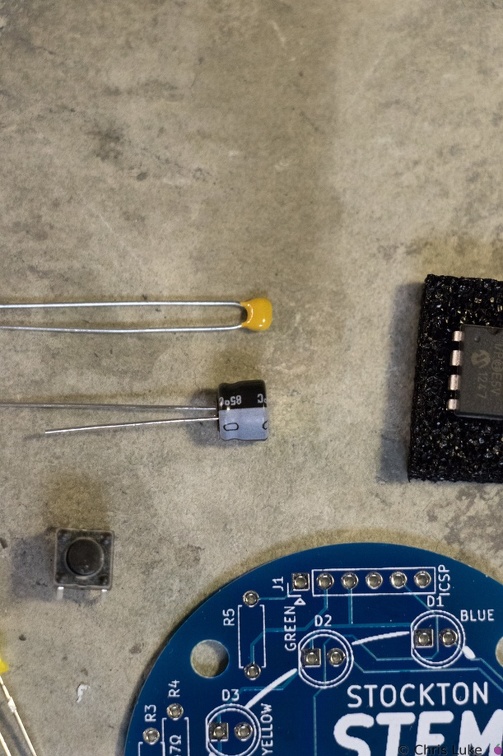

Electrolytic capacitors are polarity sensitive; note the "-" symbol on one side of the capacitor package. These capacitors typically have a larger capacity than their ceramic counterparts and are used for bulk storage; this one is used to assist the battery when the LEDs turn on. This is necessary because button cell batteries are not designed to provide as much power as the LEDs can demand. Stockton STEM Badge IC socket

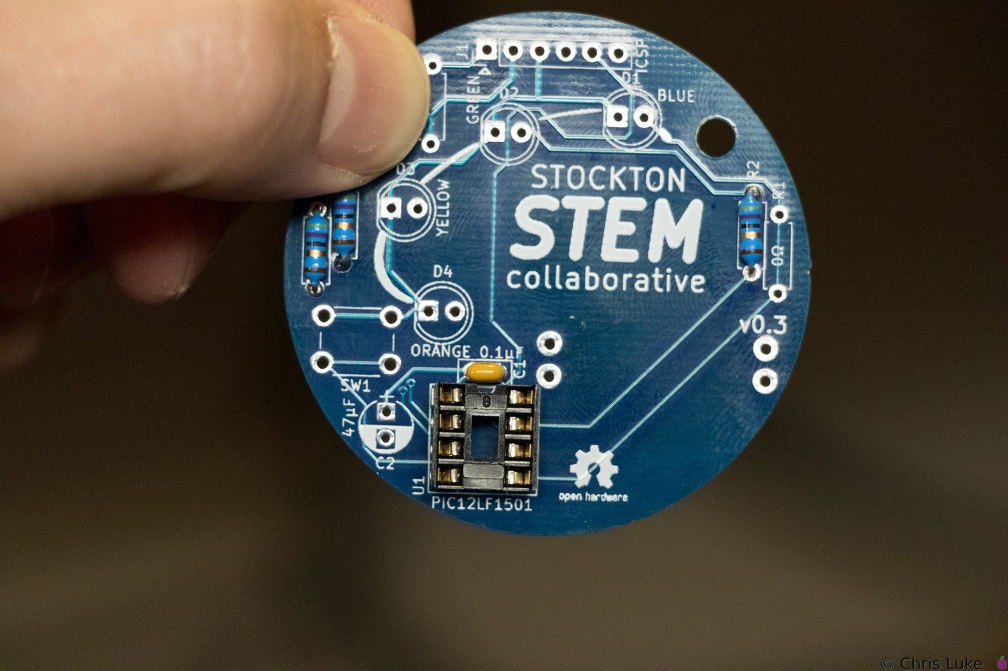

Stockton STEM Badge IC socket

Soldered legs. Stockton STEM Badge IC socket

Stockton STEM Badge IC socket

Soldering one leg first and checking that the socket is flat against the board avoids a simple mistake. If it is not flat, or otherwise misaligned simply re-heating the leg will help correct the issue. Once orientation and alignment is verified, solder the remaining legs. Sometimes a small shim, such as the black foam here, can help keep the board level and simplifies the task. Stockton STEM Badge IC socket

Stockton STEM Badge IC socket

The IC socket should lay flat against the board. Stockton STEM Badge IC socket

Stockton STEM Badge IC socket

Note the orientation of the indent at the upper edge of the IC socket. Stockton STEM Badge decoupling capacitor

Stockton STEM Badge decoupling capacitor

As with the resistors, the legs should be splayed a little to help hold it in place for soldering. Stockton STEM Badge decoupling capacitor

Stockton STEM Badge decoupling capacitor

The capacitor should sit flush with the board. Stockton STEM Badge decoupling capacitor

Stockton STEM Badge decoupling capacitor

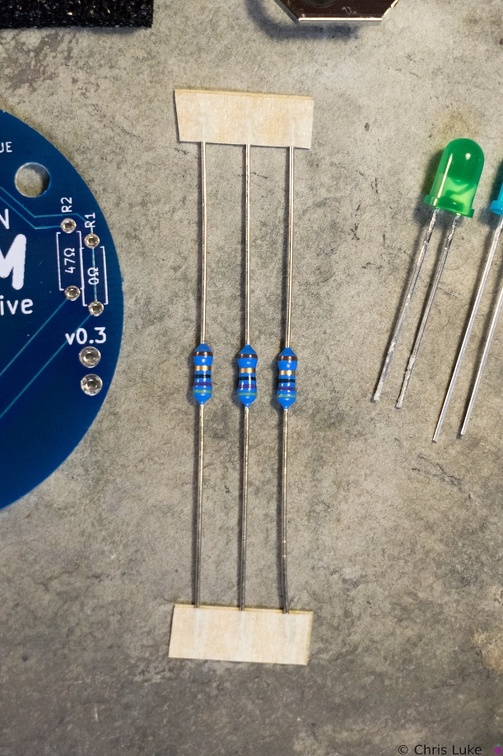

This ceramic capacitor is not orientation sensitive. Decoupling means it absorbs electrical noise and is used to filter the power feeding the microcontroller. Stockton STEM Badge resistor legs

Stockton STEM Badge resistor legs

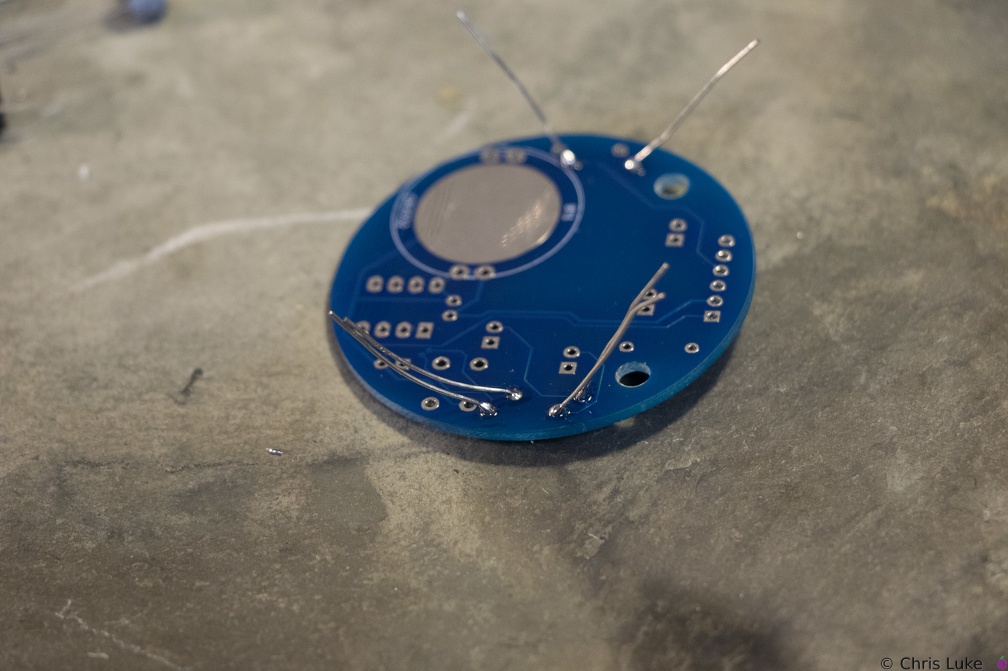

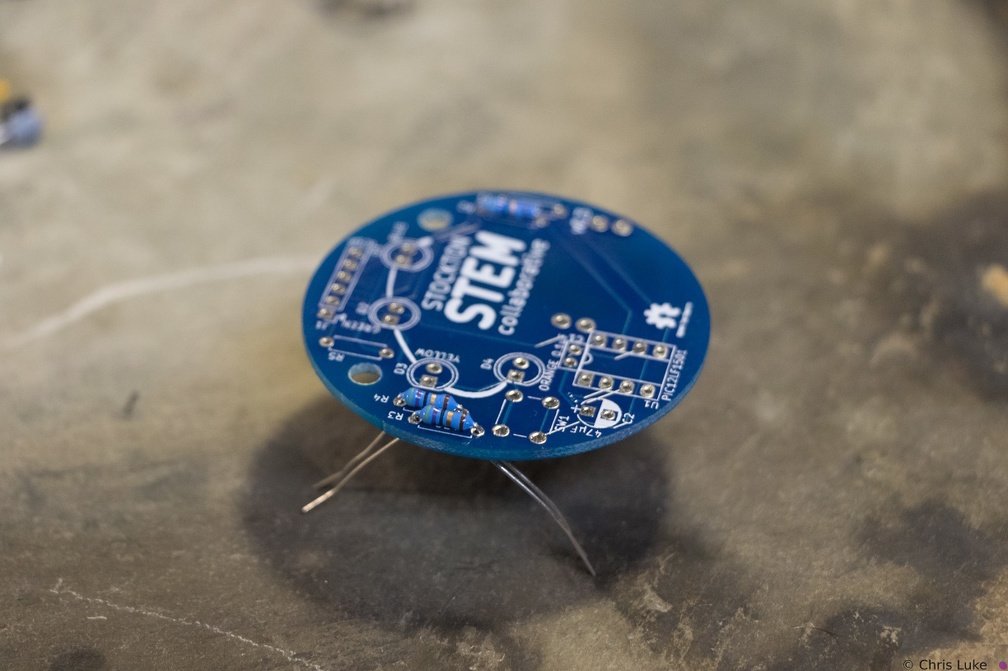

The legs are trimmed, the excess removed with side-cutters. Stockton STEM Badge resistor legs

Stockton STEM Badge resistor legs

Soldered legs; only a small amount of solder is needed and it heat should be applied only briefly. Stockton STEM Badge resistor legs

Stockton STEM Badge resistor legs

The legs are then carefully bent to about 45 degrees to hold the resistor in place for soldering. Stockton STEM Badge resistor legs

Stockton STEM Badge resistor legs

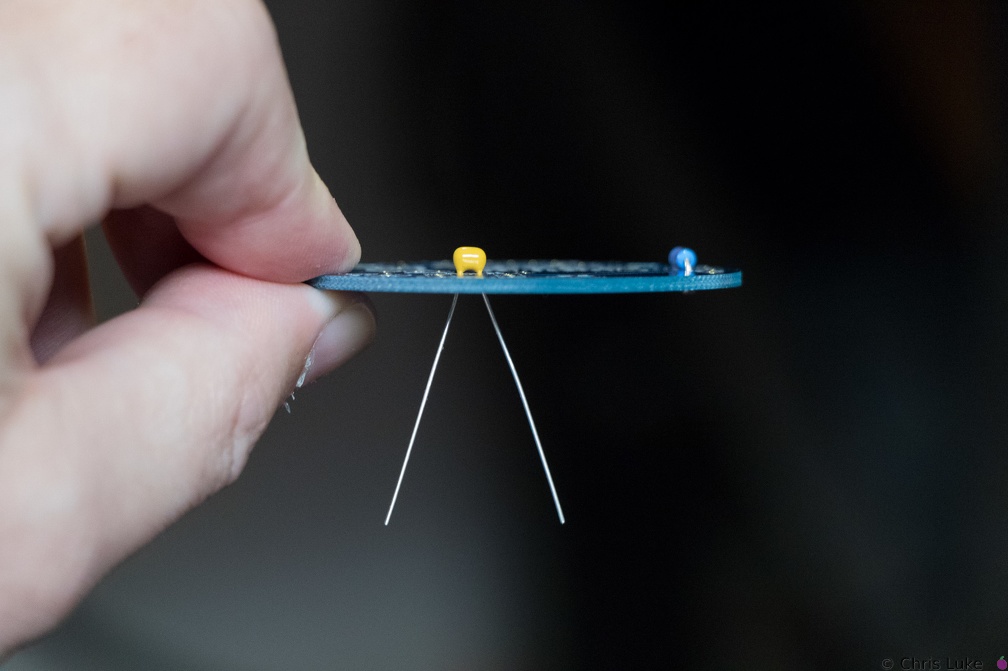

The legs are passed through the board holes; they may need pulling firmly, but not too firmly, with pliers to pull the resistor body flush with the board. Stockton STEM Badge resistor legs

Stockton STEM Badge resistor legs

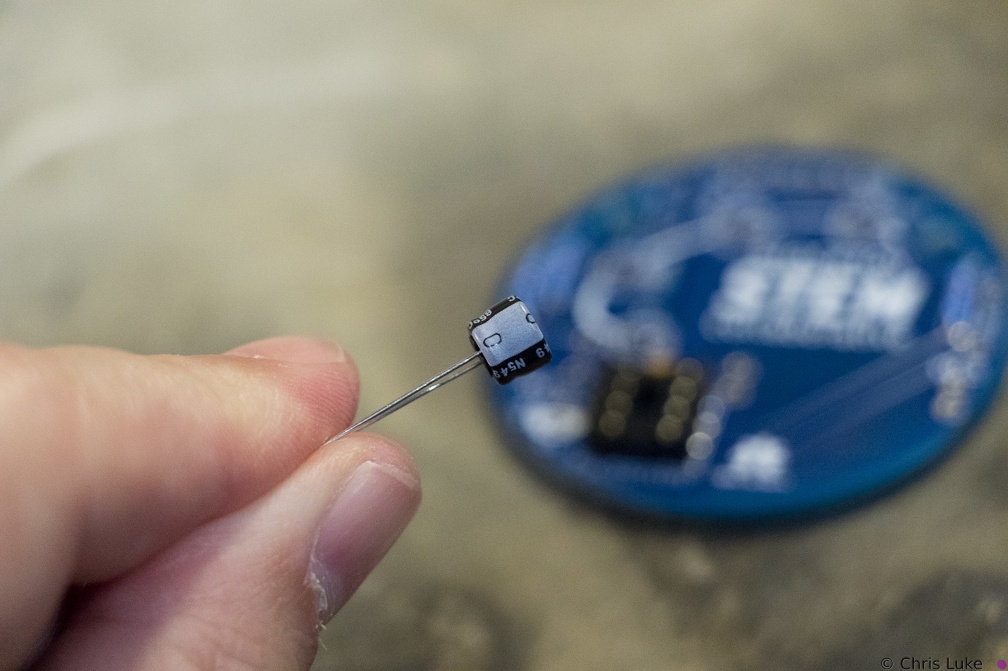

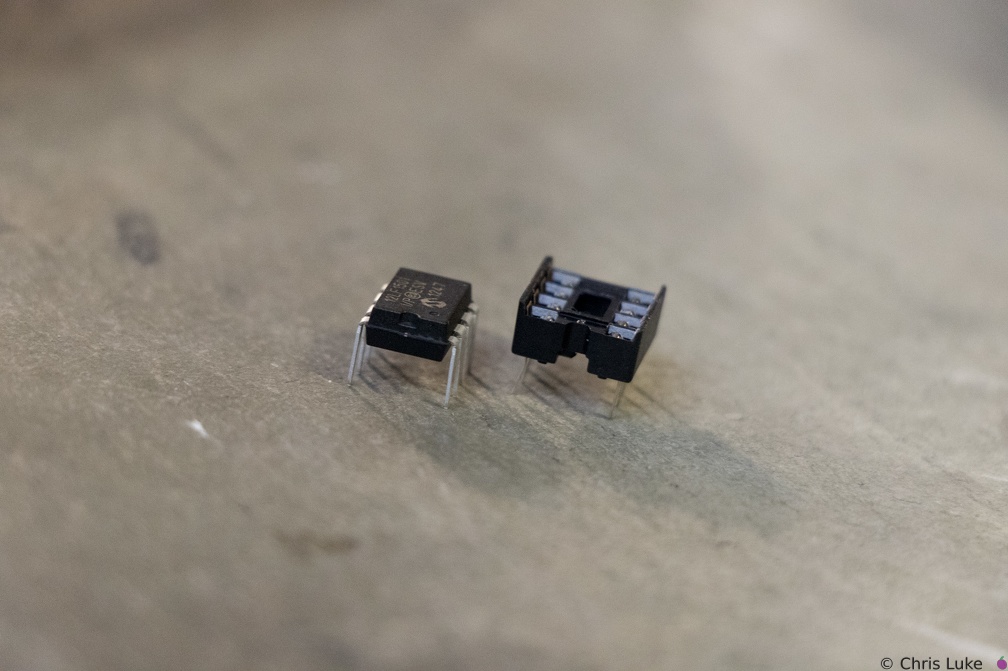

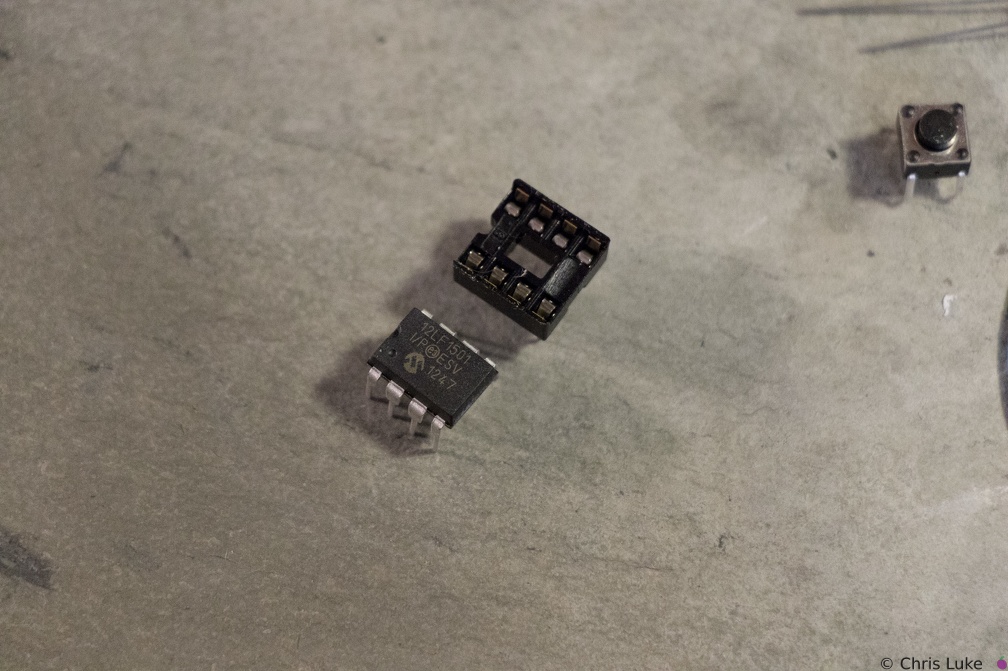

The resistor legs need to be bent in order to insert them into the board. Stockton STEM Badge IC and socket

Stockton STEM Badge IC and socket

The legs of the chip need to be straight otherwise they will not properly insert into their positions in the socket. It is easy to bend or break the legs if care is not taken. Stockton STEM Badge IC and socket

Stockton STEM Badge IC and socket

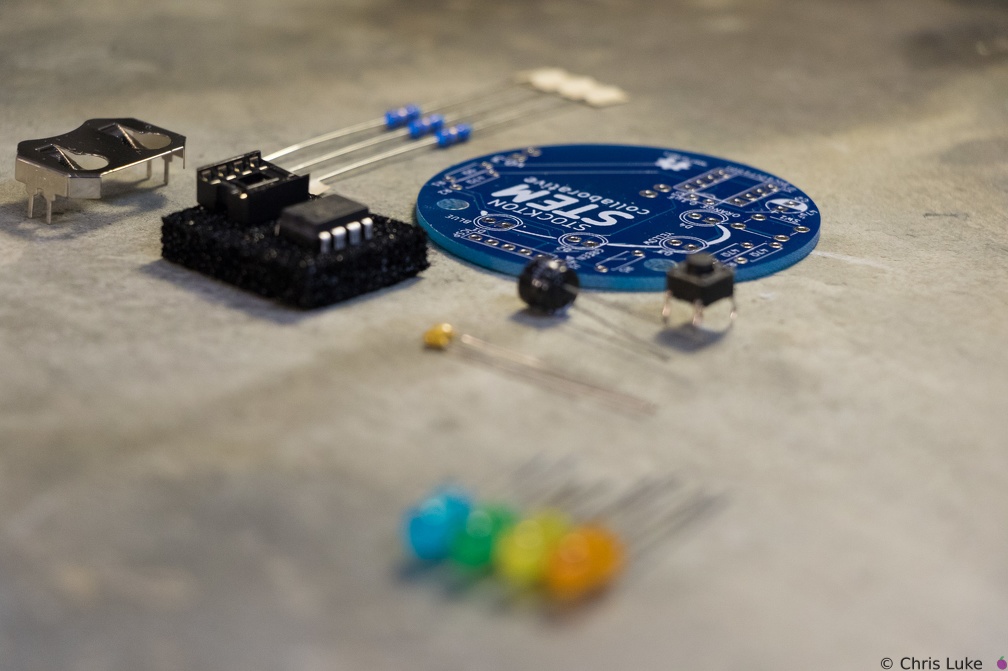

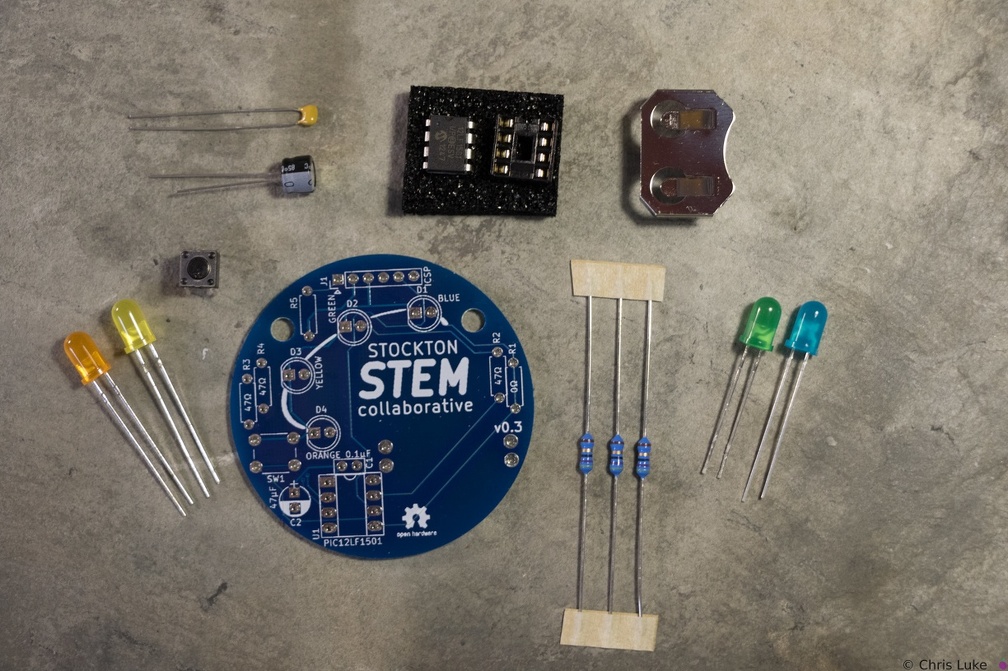

The chip, an integrated circuit, or IC, must also be used the correct way round. Both the chip and its socket have a notch at one end to identify its orientation. Stockton STEM Badge components

Stockton STEM Badge components Stockton STEM Badge LEDs

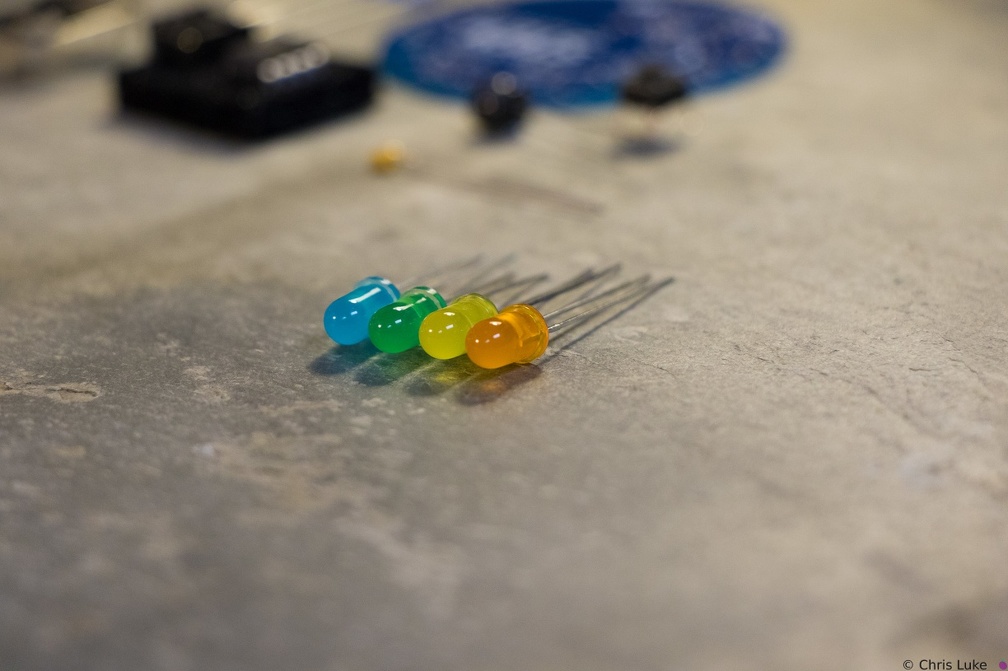

Stockton STEM Badge LEDs Stockton STEM Badge LEDs

Stockton STEM Badge LEDs Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

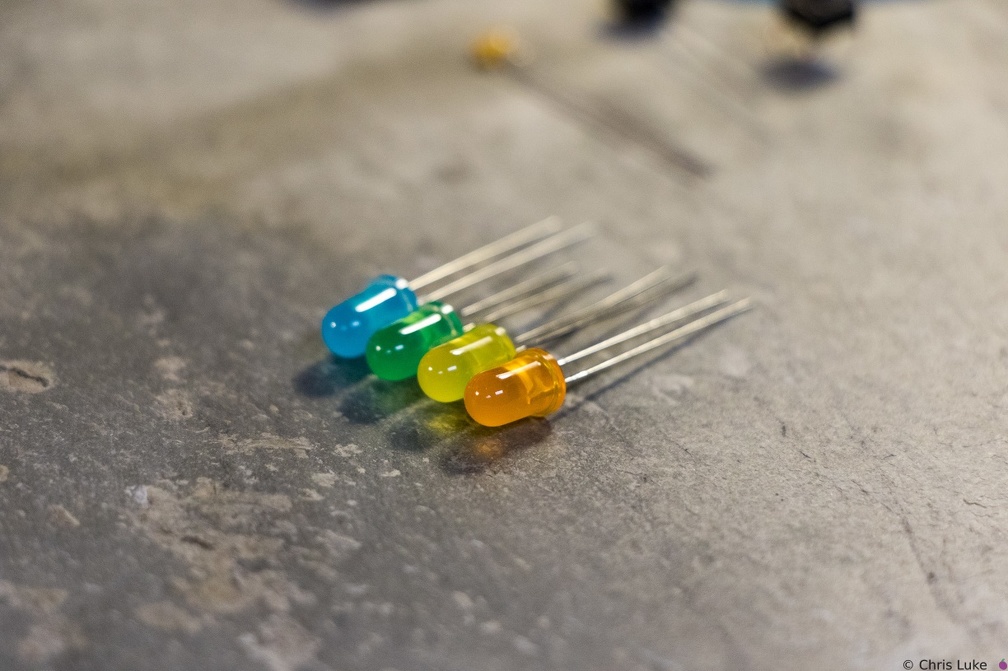

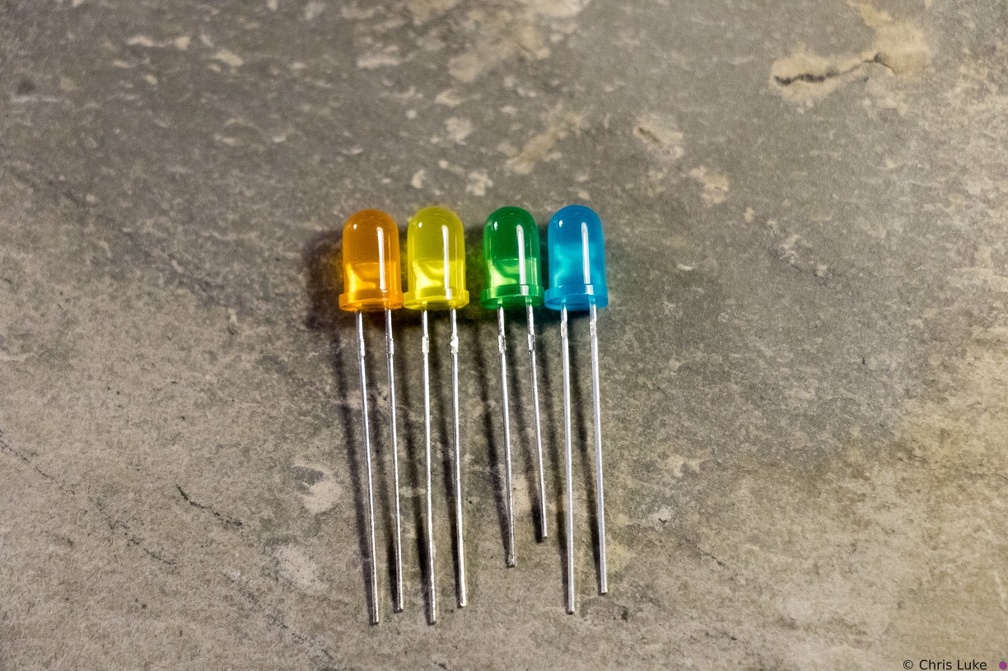

Notice how the LEDs typically have one leg longer than the other; this is called the "anode". The colored case also has one flat side, opposite the longer leg; the leg on this side is called the "cathode". Also, note the distinctive shape of what is inside the colored case; this can also be used to help determine its orientation. The gap at the top of the metal surface is always on the anode side. LEDs can only be used the right way round so determining orientation is important. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

Green and blue LEDs Stockton STEM Badge LEDs and button

Stockton STEM Badge LEDs and button

Orange and yellow LEDS. The pushbutton switch allows a person to control the badge. Stockton STEM Badge capacitors

Stockton STEM Badge capacitors

The capacitors smooth the power on the badge. The top capacitor, is not polarity sensitive; that is, it can be used either way round. The other capacitor must be used only the correct way round; the case has a "-" symbol printed on it. Stockton STEM Badge resistors

Stockton STEM Badge resistors

These are 47 ohm resistors; they limit the current supplied to the orange, yellow and green LEDs. The blue LED does not require one. Stockton STEM Badge microcontroller

Stockton STEM Badge microcontroller

The chip is an inexpensive "PIC" microcontroller; this runs a program that controls the LEDs. Stockton STEM Badge components

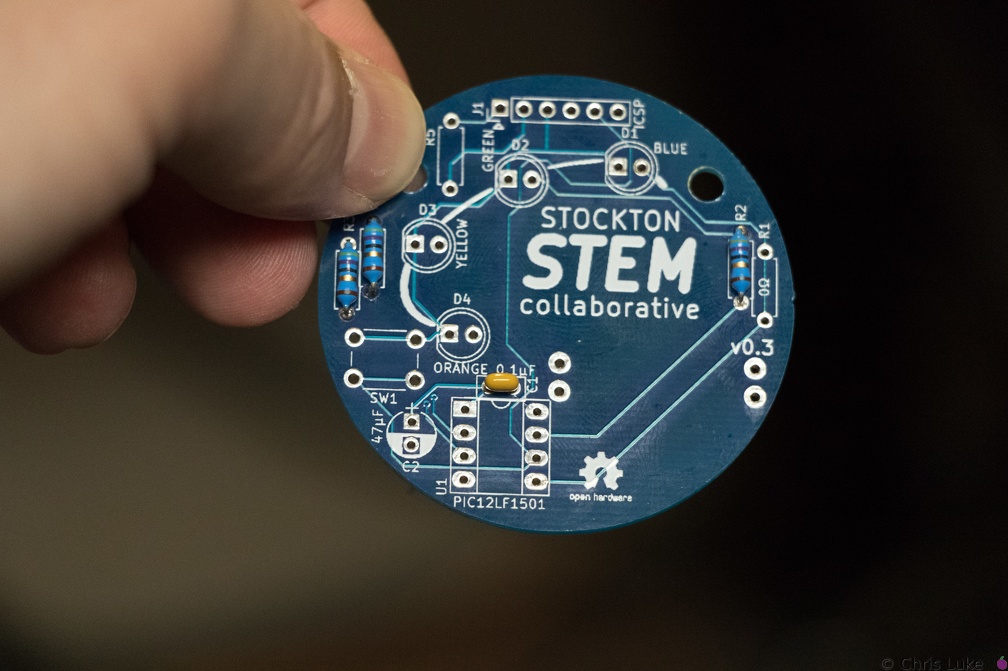

Stockton STEM Badge components

The badge consists of a handful of electronic components. Components R1, R5 and J1 are not normally populated. Stockton STEM Badge boards

Stockton STEM Badge boards

The badge printed circuit board (PCB) comes in several colors. 3C2A4164

3C2A4164 3C2A4154

3C2A4154 3C2A4144

3C2A4144 3C2A4142

3C2A4142 3C2A4137

3C2A4137 3C2A4135

3C2A4135 3C2A4132

3C2A4132 3C2A4130

3C2A4130 3C2A4125

3C2A4125 3C2A4118

3C2A4118 3C2A4112

3C2A4112 3C2A4111

3C2A4111 3C2A4110

3C2A4110 3C2A4107

3C2A4107 3C2A4097

3C2A4097 3C2A4095

3C2A4095 3C2A4091

3C2A4091 3C2A4090

3C2A4090 3C2A4088

3C2A4088 3C2A4086

3C2A4086 3C2A4081

3C2A4081 3C2A4058

3C2A4058 3C2A4054

3C2A4054 3C2A4052

3C2A4052 3C2A4051

3C2A4051 3C2A4025

3C2A4025 3C2A4016

3C2A4016 3C2A4015

3C2A4015 3C2A4014

3C2A4014 3C2A4011

3C2A4011 3C2A4009

3C2A4009- IMG 5997

- IMG 5996

- IMG 5995

- IMG 5994

- IMG 5993

- IMG 5992

- IMG 5991

- IMG 5990

- IMG 5989

- IMG 5988

- IMG 5987

- IMG 5985

- IMG 5986

- IMG 5984

- IMG 5982

- IMG 5983

- IMG 5980

- IMG 5981

- IMG 5979

- IMG 5978

- IMG 5977

- IMG 5976

- IMG 5974

- IMG 5973

- IMG 5970

- IMG 5969

- IMG 5967

- IMG 5966

- IMG 5964

- 2015-01-26 017

- 2015-01-26 016

- 2015-01-26 015

- 2015-01-26 014

- 2015-01-26 012

- 2015-01-26 011

- 2015-01-26 010

- 2015-01-26 009

- 2015-01-26 008

- 2015-01-26 007

- 2015-01-26 006

- 2015-01-26 005

- 2015-01-26 004

- 2015-01-26 003

- 2015-01-26 002

- 2015-01-26 001

- IMG 1809

- IMG 1808

- IMG 1807

- IMG 1806

- IMG 1805

- IMG 1804

- IMG 1803

- IMG 1802

- IMG 1801

- IMG 1800

- IMG 1799

- IMG 1798

- IMG 1797

- IMG 1796

- IMG 1795

- IMG 1794

- IMG 1793

- IMG 1792

- IMG 1791

- IMG 1790

- IMG 1789

- IMG 1788

- IMG 1787

- IMG 1786

- IMG 1785

- IMG 1784

- IMG 1783

- IMG 1782

- IMG 1781

- IMG 1780

- IMG 1779

- IMG 1778

- IMG 1777

- IMG 1776

- 133 3368

- 133 3367

- 133 3366

- 133 3365

- 133 3364

- 133 3363

- 133 3362

- 133 3361

- 133 3360

- 133 3359

- 133 3358

- 133 3357

- 132 3219

- 132 3218

- 132 3217

- 132 3216

- 132 3215

- 132 3213

- 132 3212

- 132 3211

- 132 3210

- 132 3209

- 132 3208

- 132 3207

- 132 3206

- 132 3205

- 132 3204

- 132 3203

- 132 3202

- 119 1939

- DSC00112

- DSC00111

- DSC00110

- DSC00109

- DSC00108

- DSC00107

- DSC00106

- DSC00105

- DSC00104