« Saturday

- 3C2A3282

- 3C2A3284

- 3C2A3288

- 3C2A3290

- 3C2A3292

- 3C2A3294

- 3C2A3295

- 3C2A3297

- 3C2A3300

- 3C2A3304

- 3C2A3306

- 3C2A3309

- 3C2A3318

- 3C2A3324

- 3C2A3330

- 3C2A3331

- 3C2A3332

- 3C2A3341

- b0001

Dartmouth Street [1/4] - b0002

Dartmouth Street [2/4] - b0003

Dartmouth Street [3/4] - b0004

Dartmouth Strete [4/4] - b0005

Heart-somethingorothers [1/4] - b0006

Heart-somethingorothers [2/4] - b0007

Heart-somethingorothers [3/4] - b0008

Heart-somethingorothers [4/4] - b0010

Pansies [1/2] - b0011

Pansies [2/2] - b0012

Tulips - b0013

Wasp [1/2] - b0014

Wasp [2/2] - b0016

Tigger [1/2] - b0017

Tigger [2/2] - b0018

A bird Might be a goose - b0019

Bird in a tree [1/2] Can you spot the bird? - b0020

Bird in a tree [2/2] ...it's in there somewhere - b0021

The sky - b0022

A plane - b0023

Air Canada [1/3] - b0024

Air Canada [2/3] - b0025

Air Canada [3/3] - b0026

Dartmouth Street - b0027

Merlin [1/4] - b0028

Merlin [2/4] - b0029

Merlin [3/4] - b0030

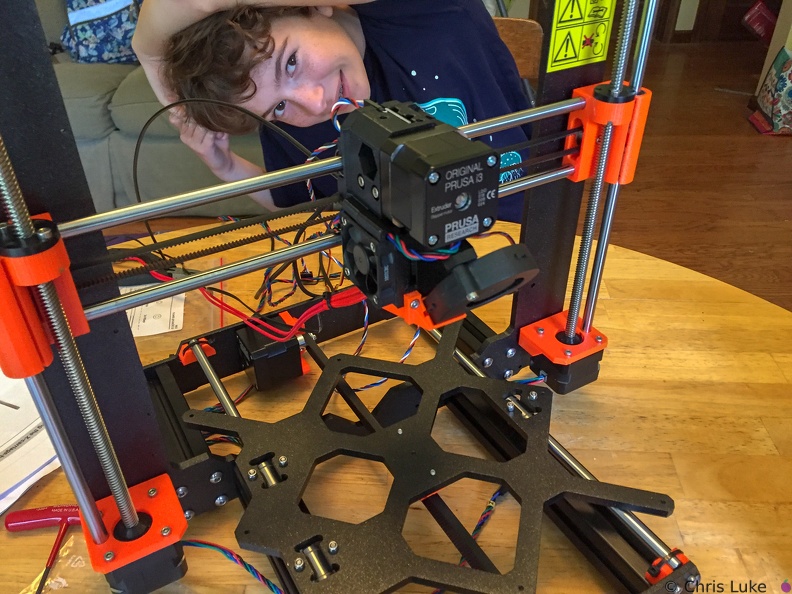

Merlin [4/4]  Baby Groot

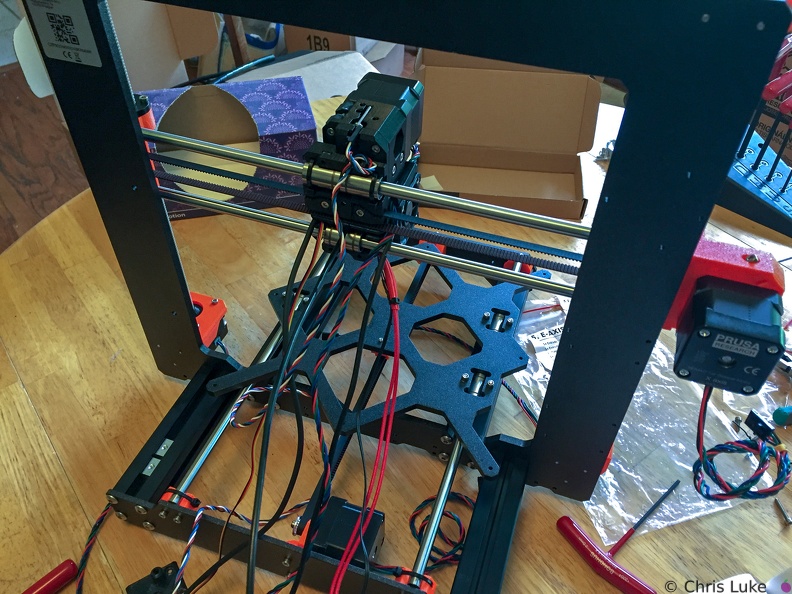

Baby Groot Cables everywhere

Cables everywhere dsc00002

dsc00002 dsc00003

dsc00003 dsc00004

dsc00004 dsc00005

dsc00005 dsc00006

dsc00006 dsc00007

dsc00007 dsc00008

dsc00008 dsc00009

dsc00009 dsc00010

dsc00010 dsc00011

dsc00011 dsc00012

dsc00012 dsc00013

dsc00013 dsc00014

dsc00014 dsc00015

dsc00015 dsc00016

dsc00016 dsc00017

dsc00017 dsc00018

dsc00018 dsc00019

dsc00019 dsc00020

dsc00020 dsc00021

dsc00021 dsc00022

dsc00022 dsc00023

dsc00023 dsc00024

dsc00024 dsc00030

dsc00030 dsc00033

dsc00033- DSC00131

The Table 2002-02-17 This is the table, a simple wooden frame with regular domestic insulation styrofoam as a surface. Here, it has been primered with Glidden "Aquacrylic Primer Ultra-Hide Gripper". - DSC00133

The Table #2 2002-02-17 - DSC00135

Under the Table 2002-02-17 An example of the structure of the wooden frame. Very simple, sturdy enough. - DSC00148

The Table 2002-02-24 An update - two loops of track, a reversing double "wye" in the centre with the points/turnouts in the process of being wired. - DSC00150

The Digitrax controller This is the controller of this layout, a Digitrax DCS-100 DCC controller. - DSC00151

The power management unit This is a Digitrax PM-4 power controller. On this layout, all the outputs are used for short circuit detection. - DSC00152

A stationary decoder This is an example of the decoder used to control the points/turnouts. I wrote the switch address of each port on the connector for diagnostics sake. - DSC00206

The first scenery 2002-04-28 The first area of scenery is started. Here we have some grass and bushes. - DSC00207

The first scenery #2 2002-04-28 More of that foliage. - DSC00208

The Table 2002-04-28 The current state of the table. The foliage in the previous two pictures is centre right. The white splotches are experiments with two types of plaster, partly to hold the track in place (and level) and partly for scenic effect. - DSC00210

The Flying Scotsman 2002-04-28 The Flying Scotsman up close with some plaster simulating the effects of rocks/debris between the two sets of track. The plaster will, if kept, eventually be coloured. - DSC00291

- DSC00402

- DSC00403

- DSC00498

Lyn and pre-wedding drinks - DSC00499

- DSC00500

- DSC00501

- DSC00502

- DSC00503

- DSC00505

- DSC00506

- DSC00508

- DSC00510

- DSC00511

- DSC00512

- DSC00513

- DSC00514

- DSC00515

- DSC00516

- DSC00519

- DSC00520

- DSC00521

- DSC00522

- DSC00523

- DSC00524

- DSC00525

- DSC00526

- DSC00527

- DSC00528

- DSC00563

- DSC00565

- DSC00566

- DSC00567

- DSC00595

- DSC00596

- DSC00597

- DSC00598

- DSC00599

- DSC00600

- DSC00605

- DSC01302

- DSC01303

- DSC01304

- DSC01305

- DSC01306

- DSC01307

- DSC01308

- DSC01309

- DSC01310

- DSC01311

First print in progress

First print in progress- grbl

The grbl controller; underneath this stepper driver is an Arduino Uno and a breakout board.  Hotend fan

Hotend fan- IMG 0645

- IMG 0646

- IMG 0647

- IMG 0648

- IMG 0649

- IMG 0650

- IMG 0651

- IMG 0652

- IMG 0653

- IMG 0654

- IMG 0655

- IMG 0656

- IMG 0657

- IMG 0658

- IMG 0659

- IMG 0660

- IMG 0661

- IMG 0662

- IMG 0663

- IMG 0664

- IMG 0665

- IMG 0666

- IMG 0667

- IMG 0668

- IMG 0669

- IMG 0670

- IMG 0671

- IMG 0672

- IMG 0673

- IMG 0674

- IMG 0675

- IMG 0847

- IMG 0848

- IMG 0849

- IMG 0850

- IMG 0851

- IMG 0852

- IMG 0853

- IMG 0854

- IMG 0855

- IMG 0856

- IMG 0857

- IMG 0858

- IMG 0859

- IMG 0860

- IMG 0861

- IMG 0862

- IMG 0863

- IMG 0864

- IMG 0865

- IMG 0866

- IMG 0867

- IMG 0868

- IMG 0869

- IMG 0870

- IMG 0871

- IMG 0872

- IMG 0873

- IMG 1072

- IMG 1078

- IMG 1079

- IMG 1080

- IMG 1421

- IMG 1422

- IMG 1423

- IMG 1425

- IMG 1427

- IMG 1429

- IMG 1430

- IMG 1431

- IMG 1432

- IMG 1433

- IMG 1438

- IMG 1440

- IMG 1441

- IMG 1443

- IMG 1444

- IMG 1445

- IMG 1446

- IMG 1447

- IMG 1448

- IMG 4054

- IMG 4055

- IMG 4056

- IMG 4057

- IMG 4058

- IMG 4064

- IMG 4070

- IMG 4071

- IMG 4072

- IMG 4077

- IMG 4078

- IMG 4080

- IMG 4081

- IMG 4086

- IMG 4087

- IMG 4088

- IMG 4091

- IMG 4092

- IMG 4093

- IMG 4094

- IMG 4095

- IMG 4096

- IMG 4097

- IMG 4099

- IMG 4101

- IMG 4102

IMG 4482

IMG 4482- IMG 5336

- IMG 5338

- IMG 5342

- IMG 5344

- IMG 5351

- IMG 5352

- IMG 5853

- IMG 5854

- IMG 5859

- IMG 5860

- IMG 5862

- IMG 5865

- IMG 5869

- IMG 5871

- IMG 5873

- IMG 5874

- IMG 5875

- IMG 5876

- IMG 5879

- IMG 5880

- IMG 5881

- IMG 5882

- IMG 5883

- IMG 5884

- IMG 5888

- IMG 5890

- IMG 5891

- IMG 5892

- IMG 5904

- IMG 5907

- IMG 5908

- IMG 5909

- IMG 5910

- IMG 5912

- IMG 5914

- IMG 5915

- IMG 5917

- IMG 5919

- IMG 5921

- IMG 5922

- IMG 5923

- IMG 5924

- IMG 5925

- IMG 5926

- IMG 5927

- IMG 5928

- IMG 5931

- IMG 5932

- IMG 5933

- IMG 5934

- IMG 5935

- IMG 5936

- IMG 5937

- IMG 5938

- IMG 5939

- IMG 5940

- IMG 5941

- IMG 5943

- IMG 5944

- IMG 5945

- IMG 5946

- IMG 6000

- IMG 6001

- IMG 6002

- IMG 7762

- IMG 7789

- IMG 7797

- IMG 7798

- IMG 7804

- IMG 7820

- IMG 7821

- IMG 7868

- IMG 7891

- IMG 7894

- IMG 7906

- IMG 7922

- IMG 7923

- IMG 7924

- IMG 8095

- IMG 8096

- IMG 8097

- IMG 8098

- IMG 8099

- IMG 8100

- IMG 8101

- IMG 8102

- IMG 8104

- IMG 8106

- IMG 8107

- IMG 8108

- IMG 8109

- IMG 8151

- IMG 8152

- IMG 8153

- IMG 8154

- IMG 8155

- IMG 8156

- IMG 8157

- IMG 8158

- IMG 8159

- IMG 8160

- IMG 8161

- IMG 8162

- IMG 8163

- IMG 8164

- IMG 8165

- IMG 8166

- IMG 8167

- IMG 8168

- IMG 8169

- IMG 8170

- IMG 8171

- IMG 8172

- IMG 8173

- IMG 8174

- IMG 8175

- IMG 8176

- IMG 8177

- IMG 8178

- IMG 8179

- IMG 8180

- IMG 8181

- IMG 8182

- IMG 8183

- IMG 8184

- IMG 8185

- IMG 8186

- IMG 8187

- IMG 8188

- IMG 8189

- IMG 8190

- IMG 8191

- IMG 8192

- IMG 8193

- IMG 8194

- IMG 8195

- IMG 8196

- IMG 8886

- IMG 8887

- IMG 9327

IMG 9327 marked

IMG 9327 marked

The lot, marked Now that we have a paved street, it's easier to tell where the lot is. The white lines mark it out.- IMG 9330

- IMG 9331

- IMG 9332

- IMG 9333

- IMG 9336

- IMG 9339

- IMG 9345

- IMG 9346

- IMG 9347

- IMG 9348

- IMG 9350

- IMG 9353

- IMG 9355

- IMG 9359

- IMG 9360

- IMG 9365

- IMG 9374

- IMG 9380

- IMG 9388

Mathematical Bridge

Mathematical Bridge Merlin's Cave

Merlin's Cave- P0000034

- P0000035

- P0000036

- P0000037

- P0000038

- P0000039

- P0000045

- P0000046

- P0000047

- P0000061

- P0000062

- P0000063

- P0000064

- P0000065

- P0000066

- P0000067

- P0000068

- P0000069

- P0000070

- P0000071

- P0000072

- P0000073

- P0000077

- P0000078

Piper vs. Apollo

Piper vs. Apollo Print head cables

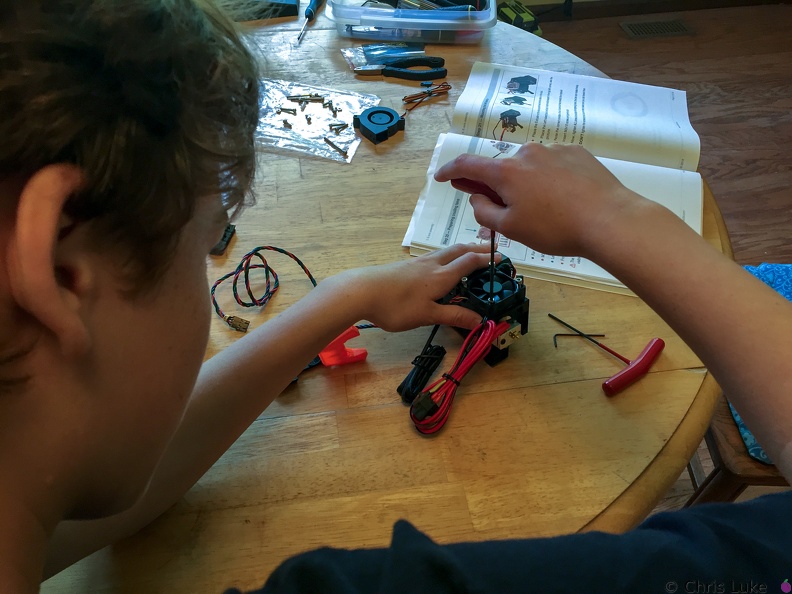

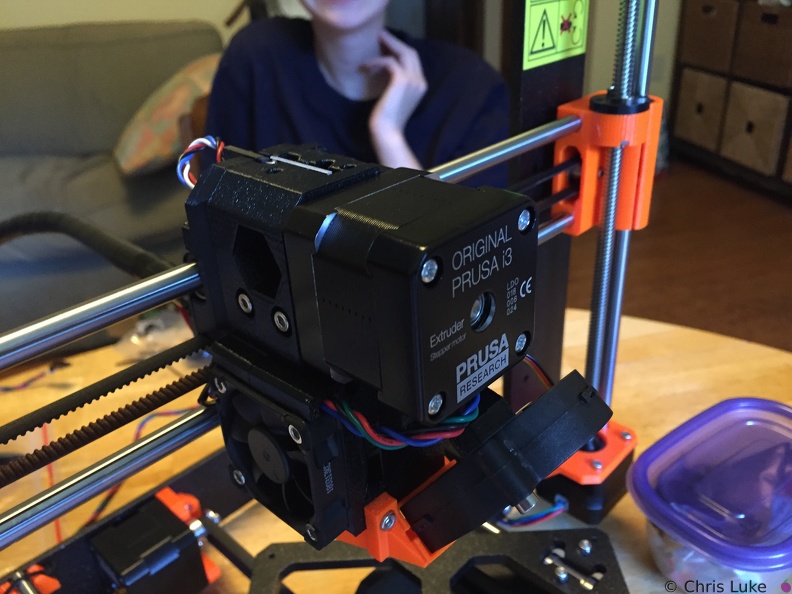

Print head cables Printhead front

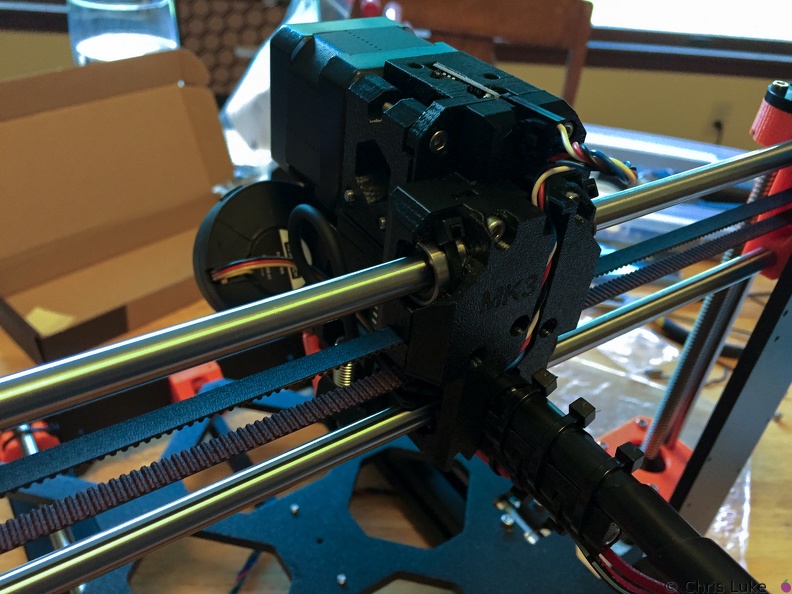

Printhead front Printhead rear

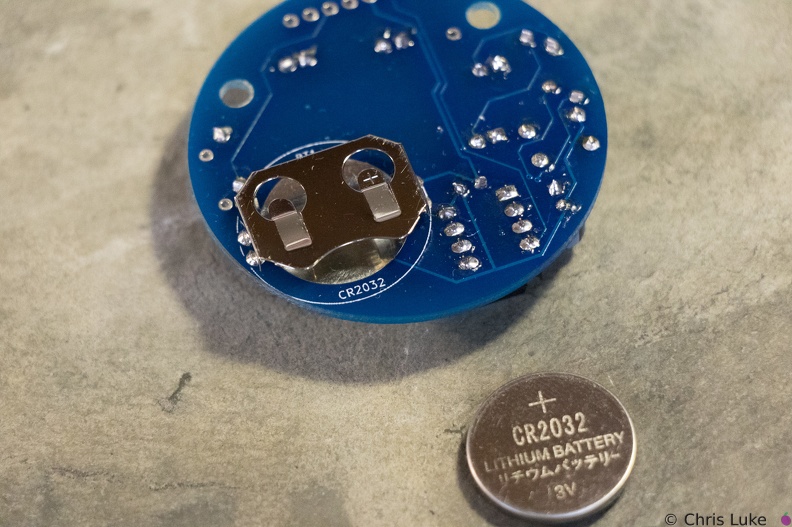

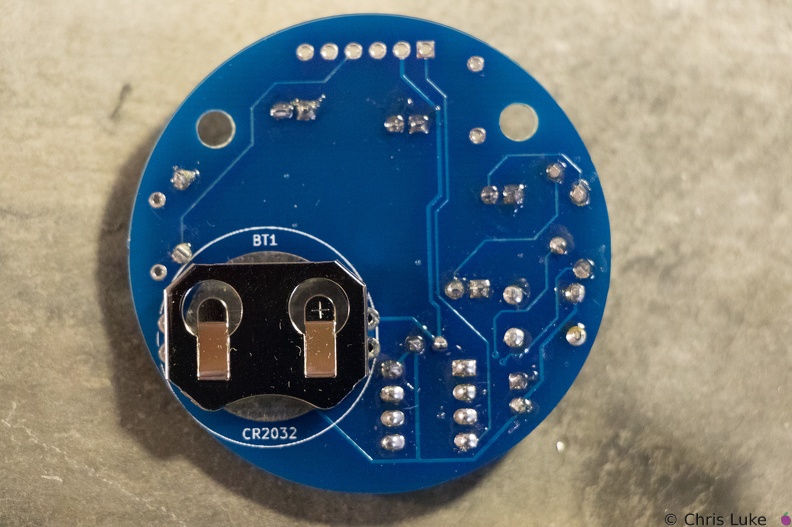

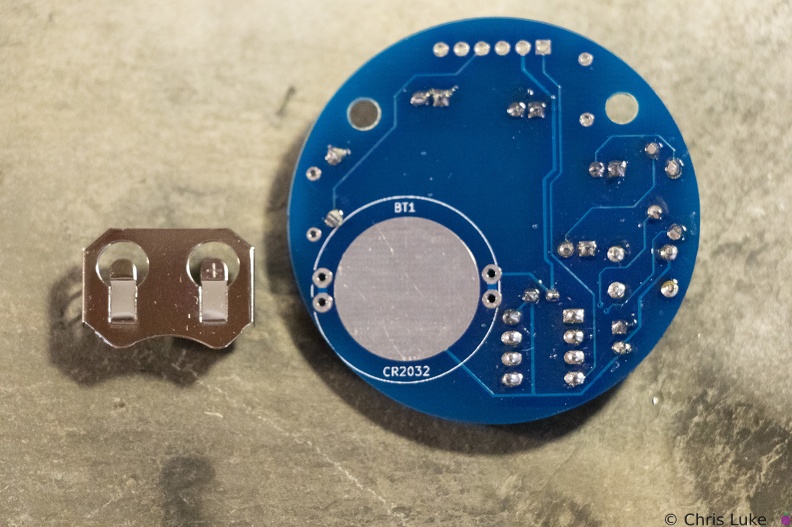

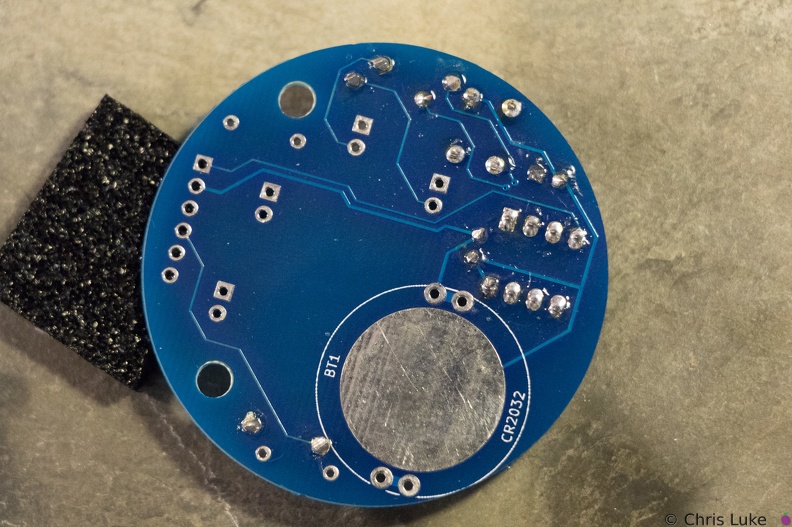

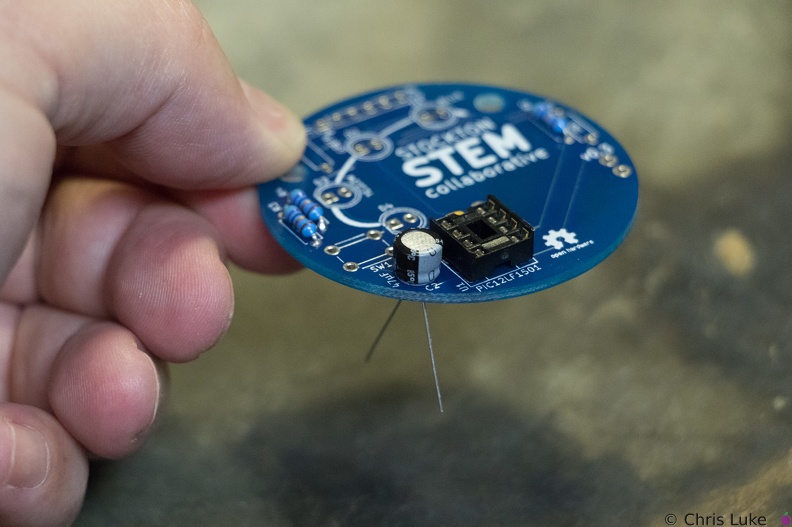

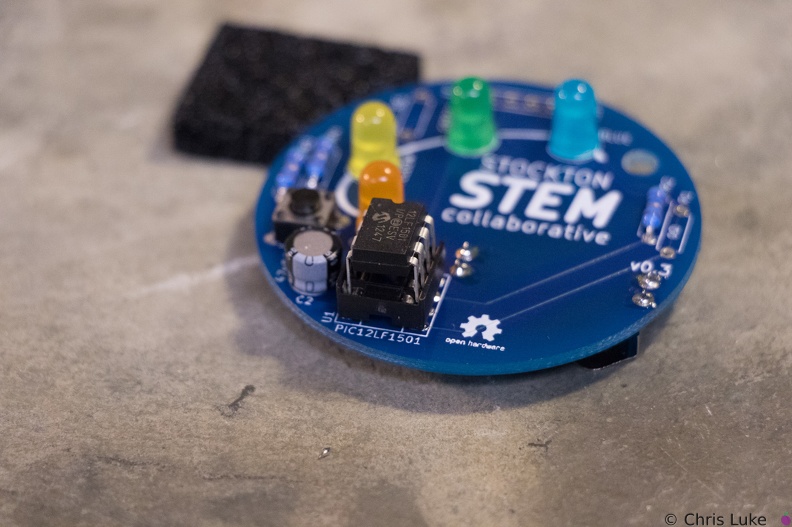

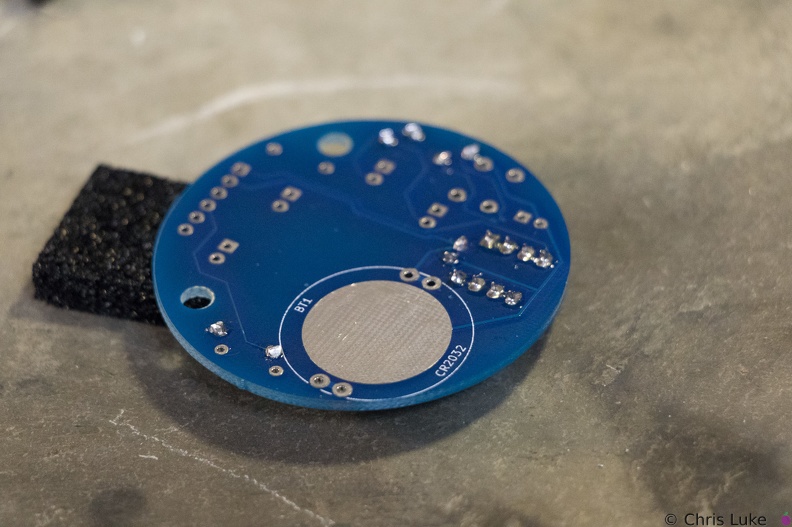

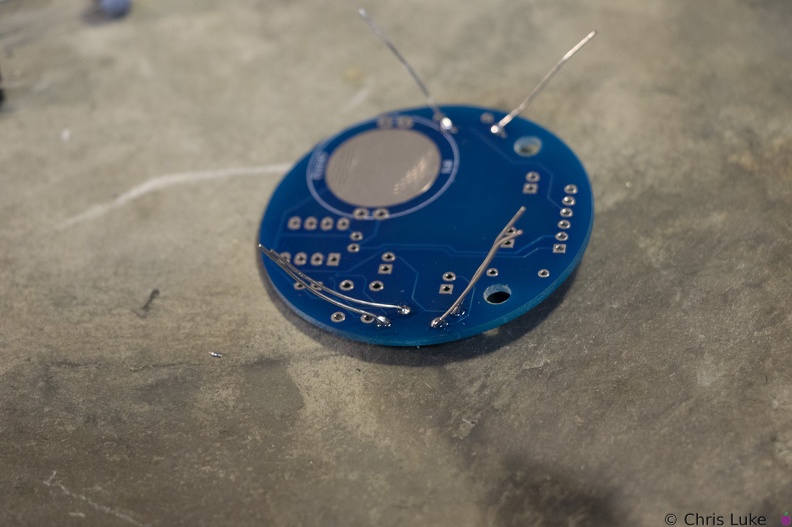

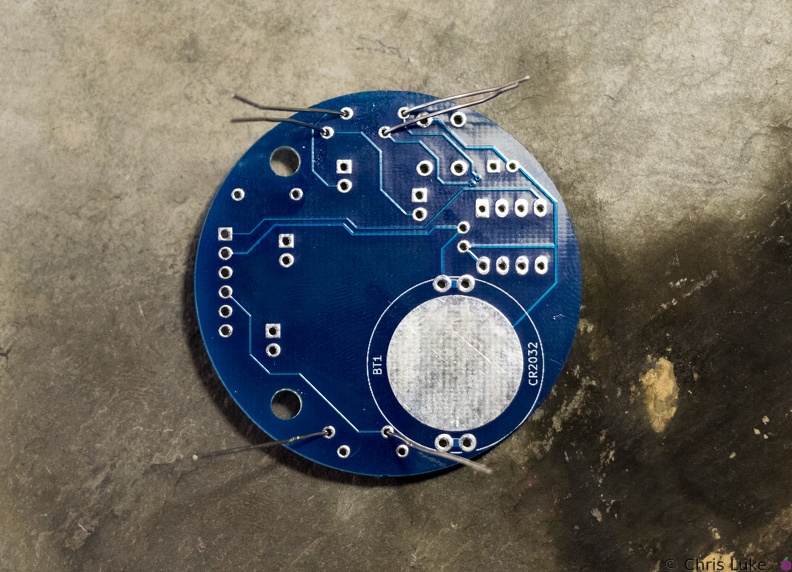

Printhead rear Stockton STEM Badge battery

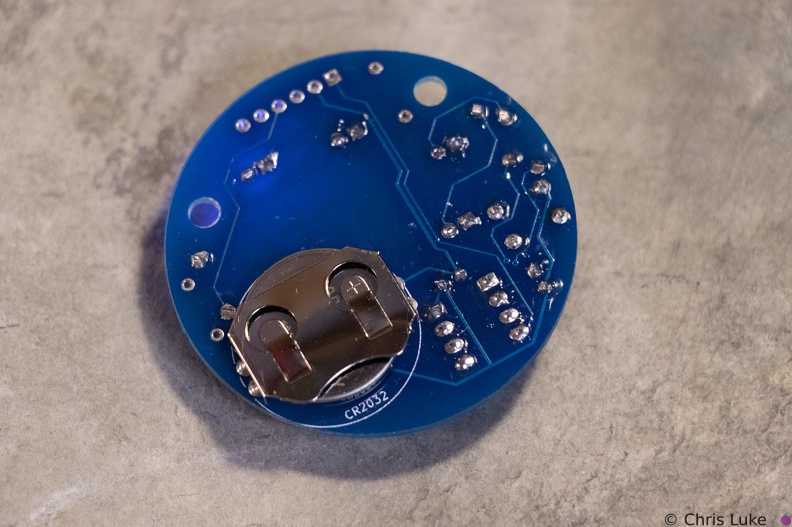

Stockton STEM Badge battery

The battery should sit snugly under the holder. Stockton STEM Badge battery

Stockton STEM Badge battery

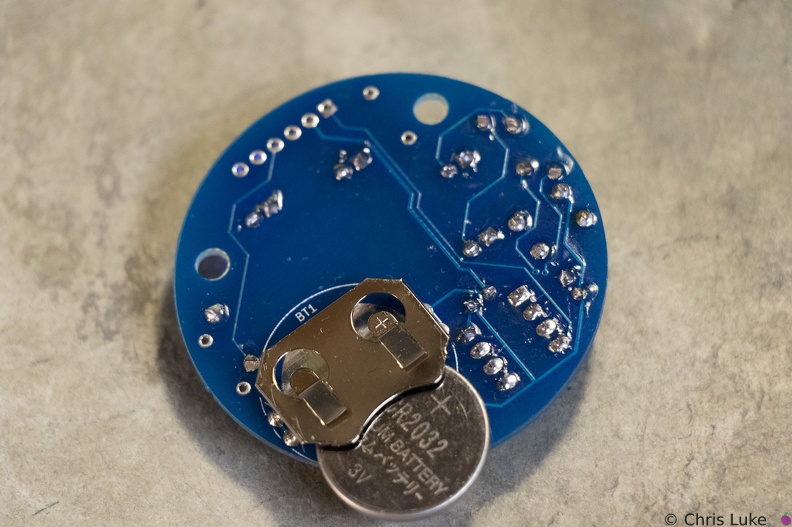

Note the orientation of the battery. The "+" side contacts the battery holder. Stockton STEM Badge battery

Stockton STEM Badge battery

The battery is a typical CR2032 button cell. Notice which side the "+" is on. Stockton STEM Badge battery

Stockton STEM Badge battery

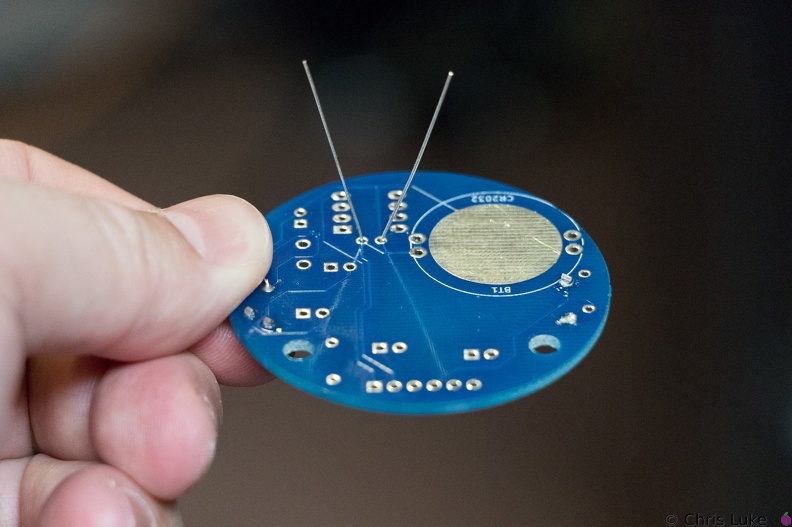

It is possible for the holder to become hot during soldering; be careful when handling immediately after soldering. Stockton STEM Badge battery

Stockton STEM Badge battery

Note the orientation of the holder; reversing it will make it difficult to insert the battery later. Stockton STEM Badge battery

Stockton STEM Badge battery

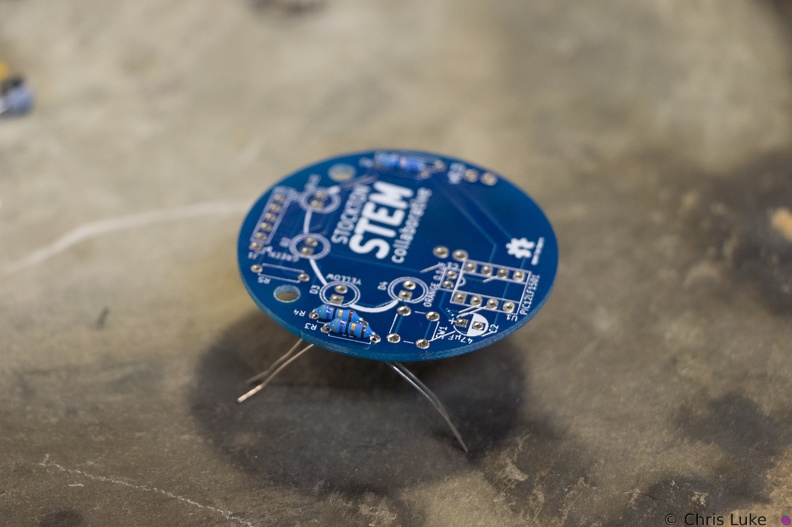

The battery holder is a simple metal cage that solders to the underside of the board. Stockton STEM Badge boards

Stockton STEM Badge boards

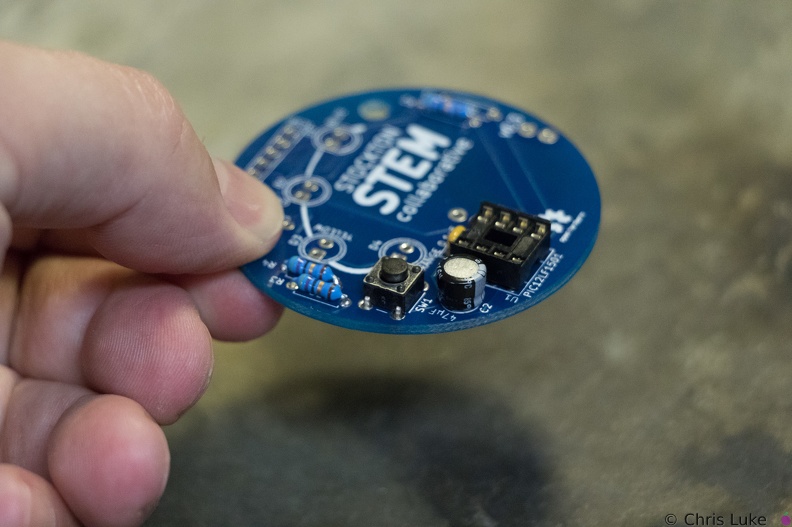

The badge printed circuit board (PCB) comes in several colors. Stockton STEM Badge button

Stockton STEM Badge button

As with the IC socket, soldering one leg first and verifying component alignment will help prevent easy mistakes. Stockton STEM Badge button

Stockton STEM Badge button

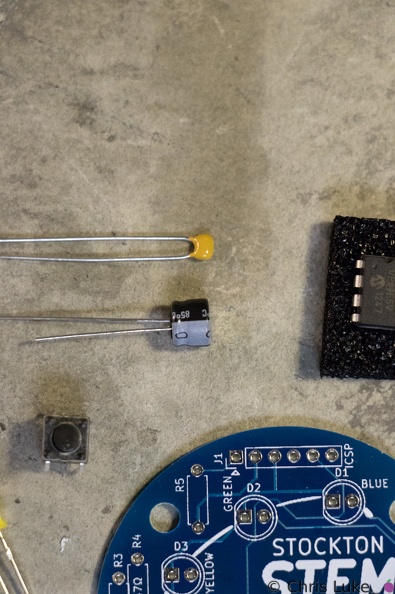

The push-button switch will fit two ways. Orientation does not matter. Stockton STEM Badge capacitors

Stockton STEM Badge capacitors

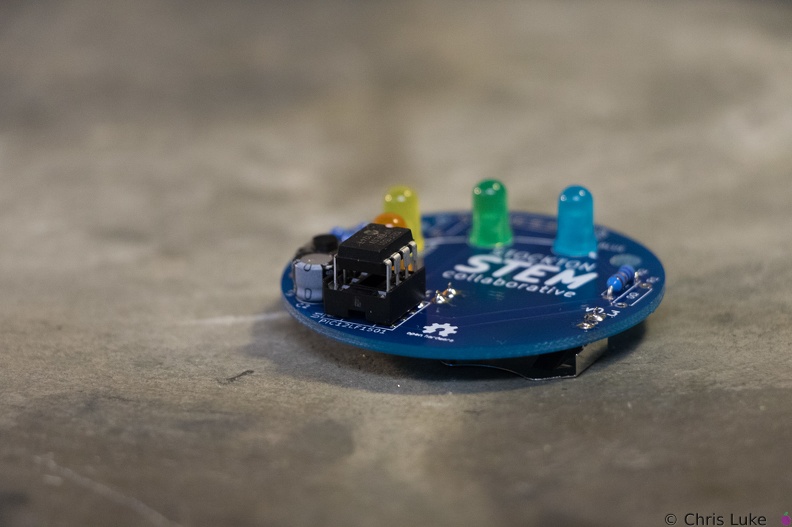

The capacitors smooth the power on the badge. The top capacitor, is not polarity sensitive; that is, it can be used either way round. The other capacitor must be used only the correct way round; the case has a "-" symbol printed on it. Stockton STEM Badge completed

Stockton STEM Badge completed

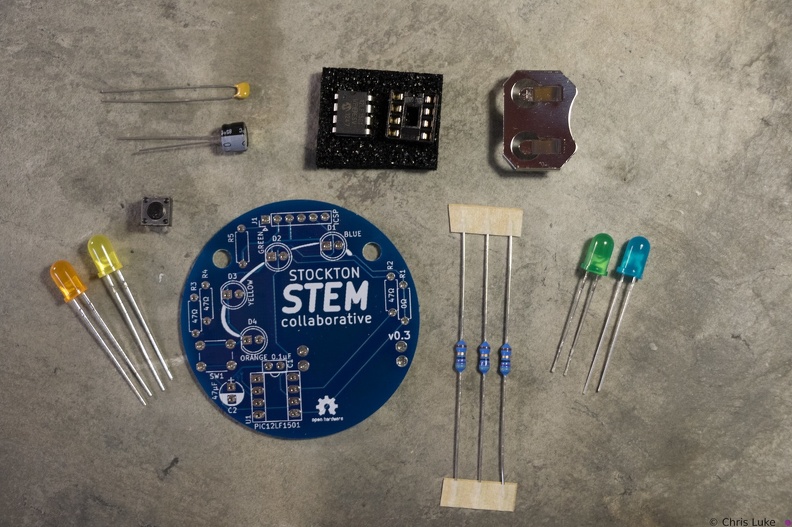

Press the button to start the lights! Stockton STEM Badge components

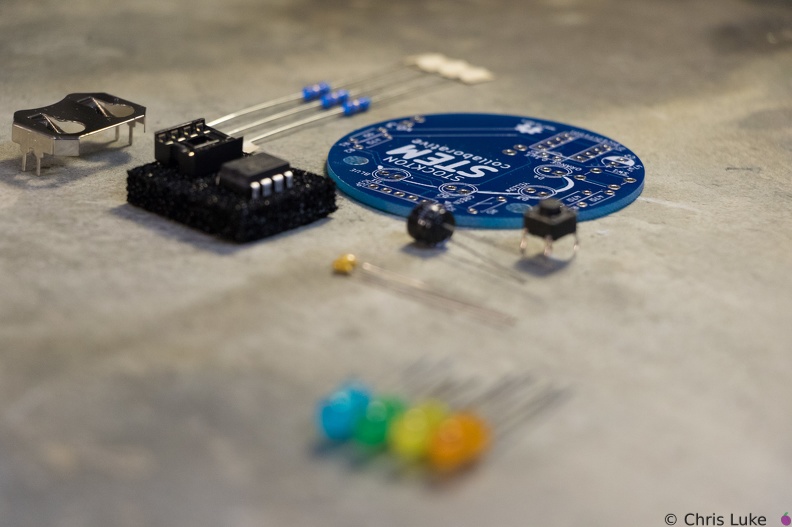

Stockton STEM Badge components Stockton STEM Badge components

Stockton STEM Badge components

The badge consists of a handful of electronic components. Components R1, R5 and J1 are not normally populated. Stockton STEM Badge decoupling capacitor

Stockton STEM Badge decoupling capacitor

As with the resistors, the legs should be splayed a little to help hold it in place for soldering. Stockton STEM Badge decoupling capacitor

Stockton STEM Badge decoupling capacitor

The capacitor should sit flush with the board. Stockton STEM Badge decoupling capacitor

Stockton STEM Badge decoupling capacitor

This ceramic capacitor is not orientation sensitive. Decoupling means it absorbs electrical noise and is used to filter the power feeding the microcontroller. Stockton STEM Badge electrolytic capacitor

Stockton STEM Badge electrolytic capacitor

Orientation of this capacitor is important. There is a "+" symbol in the footprint of the component printed on the board; the "-" of the capacitor should be on the opposite side. Stockton STEM Badge electrolytic capacitor

Stockton STEM Badge electrolytic capacitor

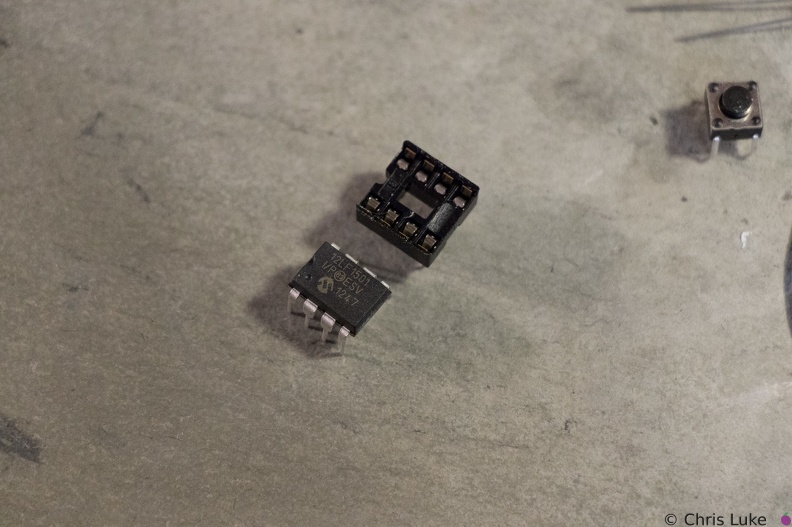

Electrolytic capacitors are polarity sensitive; note the "-" symbol on one side of the capacitor package. These capacitors typically have a larger capacity than their ceramic counterparts and are used for bulk storage; this one is used to assist the battery when the LEDs turn on. This is necessary because button cell batteries are not designed to provide as much power as the LEDs can demand. Stockton STEM Badge IC

Stockton STEM Badge IC

Once pushed all the way in, the IC may sit above the socket, but it will be parallel to it. Stockton STEM Badge IC

Stockton STEM Badge IC

Make sure the IC is correctly aligned before pushing it in. Stockton STEM Badge IC

Stockton STEM Badge IC

When inserting the IC, firm but controlled pressure is needed to avoid bending the pins. Stockton STEM Badge IC

Stockton STEM Badge IC

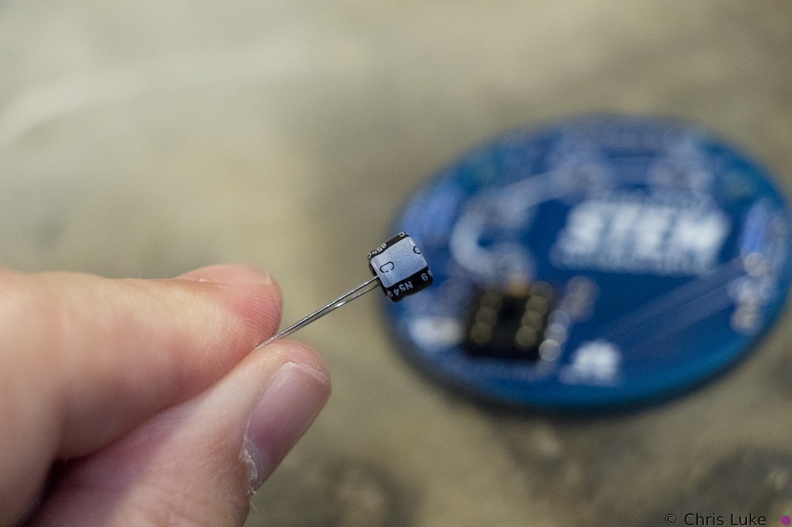

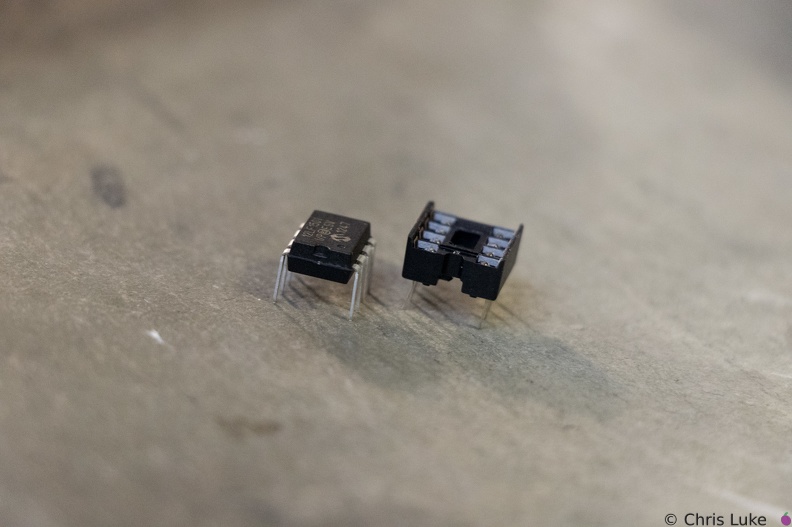

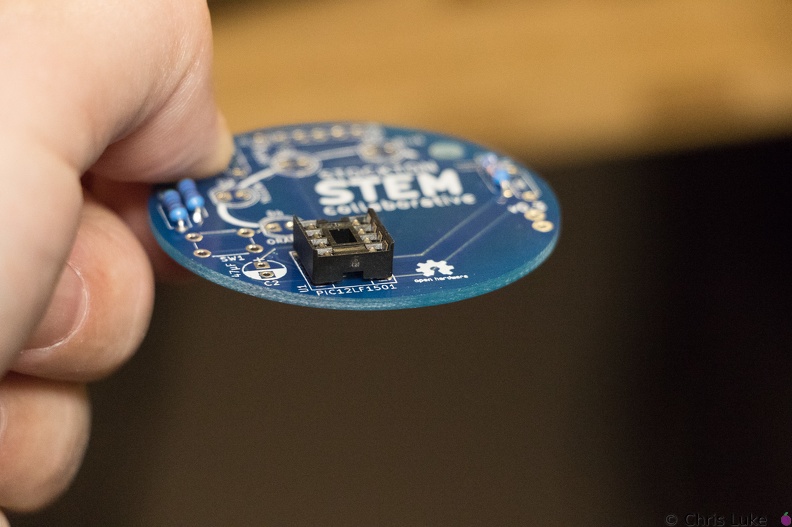

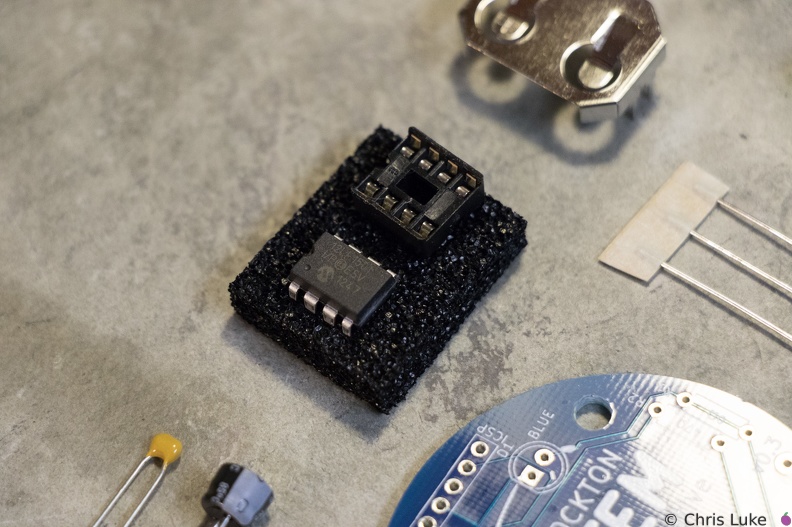

The IC pins need to be straight and line up with their receptacles in the socket. Stockton STEM Badge IC and socket

Stockton STEM Badge IC and socket

The legs of the chip need to be straight otherwise they will not properly insert into their positions in the socket. It is easy to bend or break the legs if care is not taken. Stockton STEM Badge IC and socket

Stockton STEM Badge IC and socket

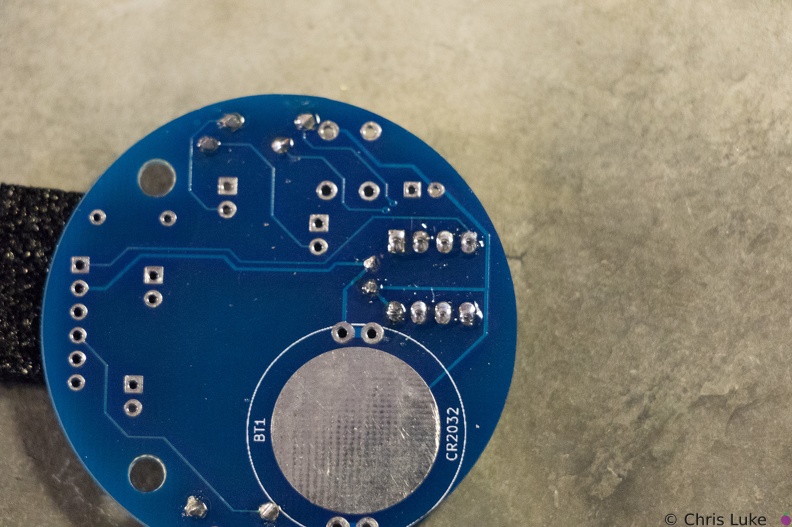

The chip, an integrated circuit, or IC, must also be used the correct way round. Both the chip and its socket have a notch at one end to identify its orientation. Stockton STEM Badge IC socket

Stockton STEM Badge IC socket

Soldered legs. Stockton STEM Badge IC socket

Stockton STEM Badge IC socket

Soldering one leg first and checking that the socket is flat against the board avoids a simple mistake. If it is not flat, or otherwise misaligned simply re-heating the leg will help correct the issue. Once orientation and alignment is verified, solder the remaining legs. Sometimes a small shim, such as the black foam here, can help keep the board level and simplifies the task. Stockton STEM Badge IC socket

Stockton STEM Badge IC socket

The IC socket should lay flat against the board. Stockton STEM Badge IC socket

Stockton STEM Badge IC socket

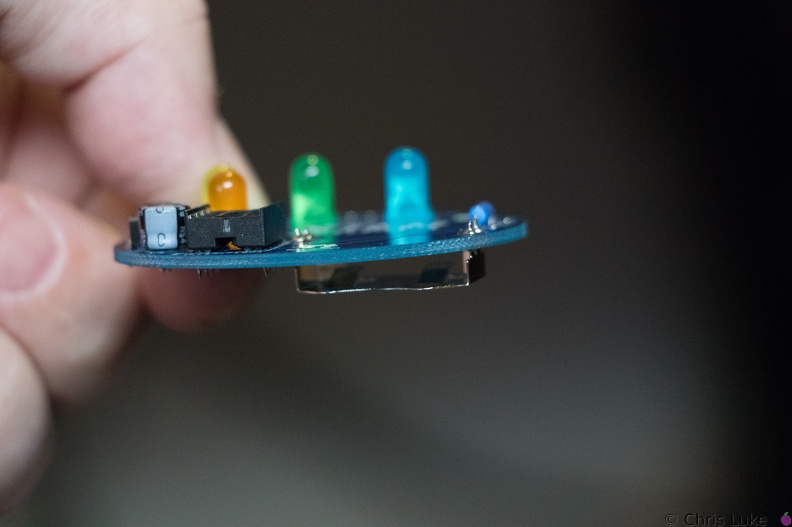

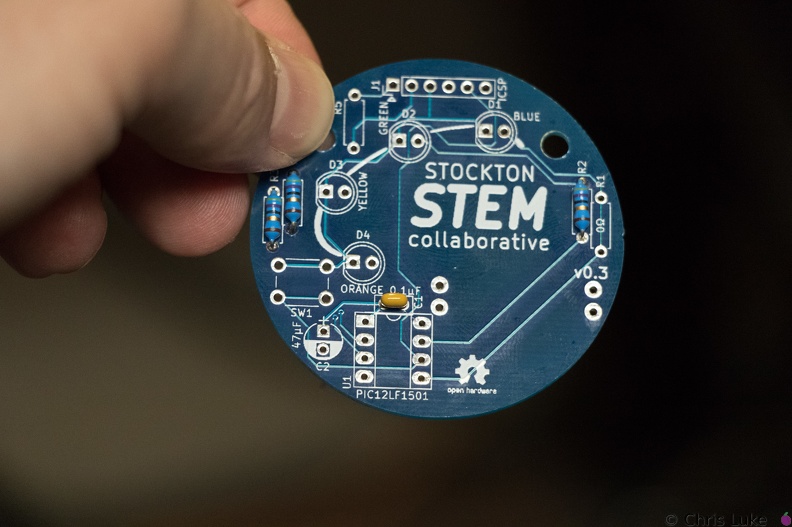

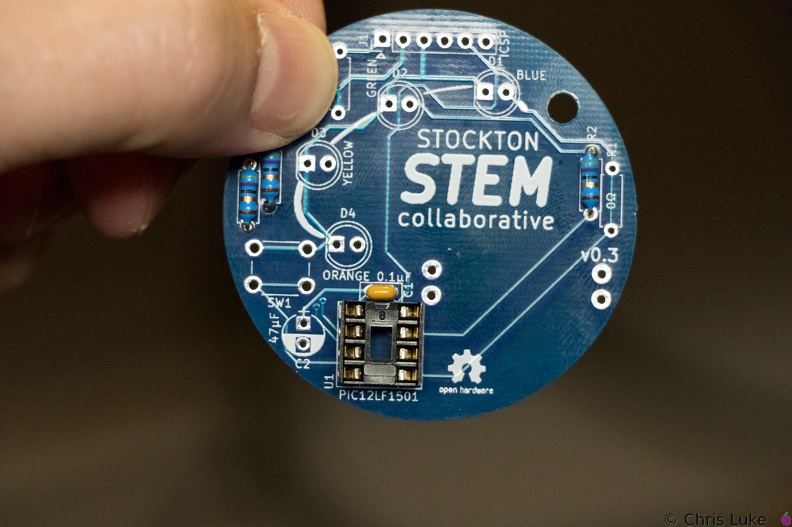

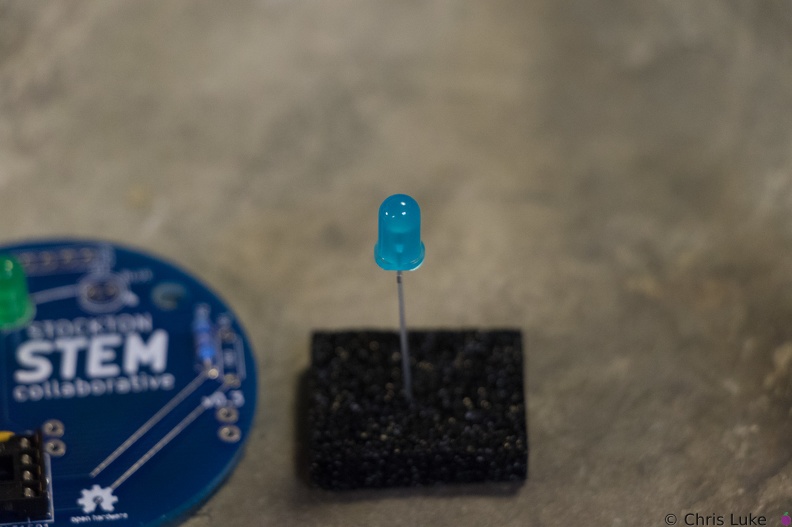

Note the orientation of the indent at the upper edge of the IC socket. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

All the LEDs have been soldered. Notice that they all have the same orientation; the flat edge is to the left. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

The case of an LED can crack if the legs are bent too close to it; even after placing the LED on the board, only bend the legs slightly to hold it in place. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

While all components can be destroyed with an excess of heat during soldering, LEDs are especially susceptible to this. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

The footprint for the LEDs also shows a flat edge; orientation of the LEDs needs to match that of the board. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

LEDs have a flat edge on one side of their case. Stockton STEM Badge LEDs

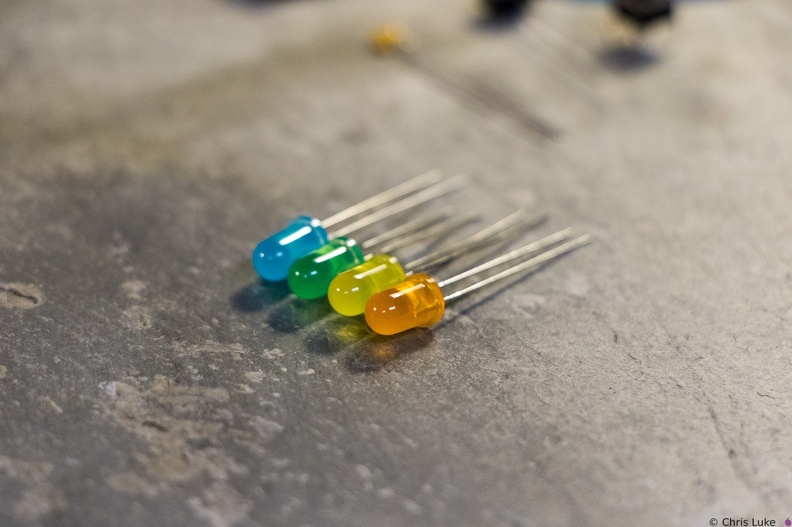

Stockton STEM Badge LEDs Stockton STEM Badge LEDs

Stockton STEM Badge LEDs Stockton STEM Badge LEDs

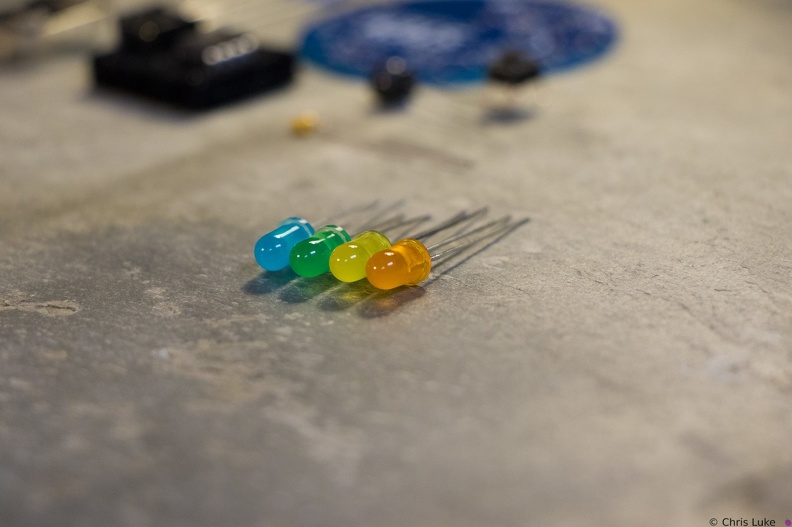

Stockton STEM Badge LEDs

Notice how the LEDs typically have one leg longer than the other; this is called the "anode". The colored case also has one flat side, opposite the longer leg; the leg on this side is called the "cathode". Also, note the distinctive shape of what is inside the colored case; this can also be used to help determine its orientation. The gap at the top of the metal surface is always on the anode side. LEDs can only be used the right way round so determining orientation is important. Stockton STEM Badge LEDs

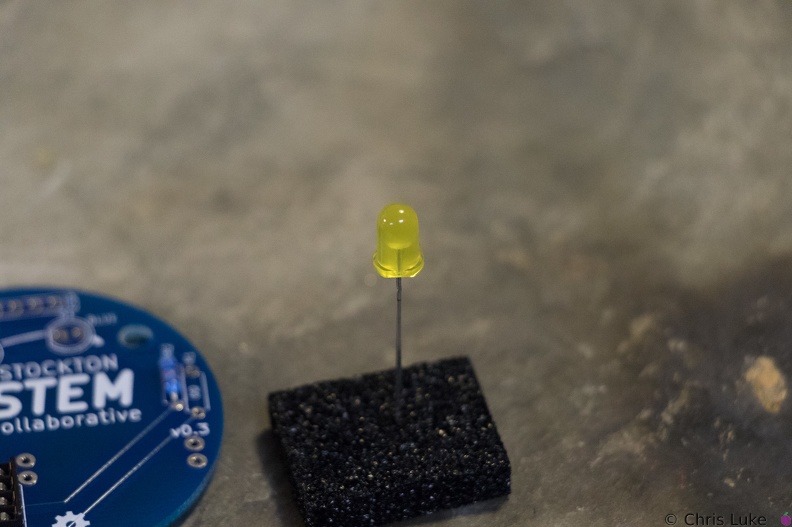

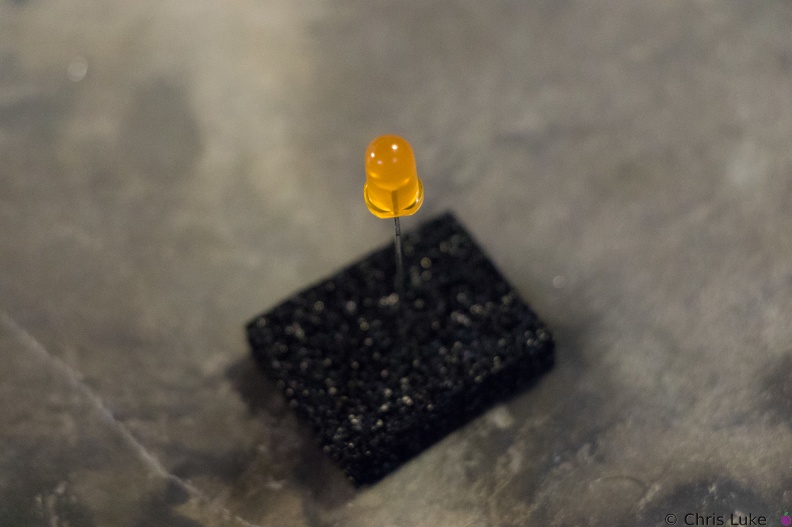

Stockton STEM Badge LEDs

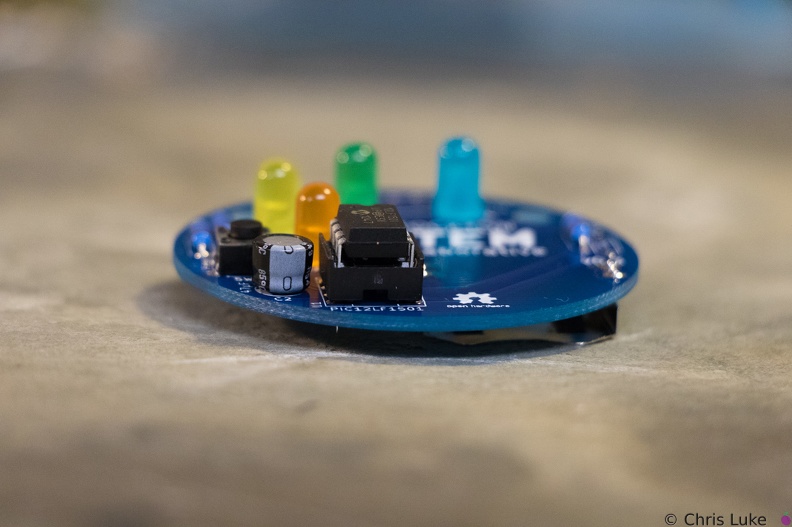

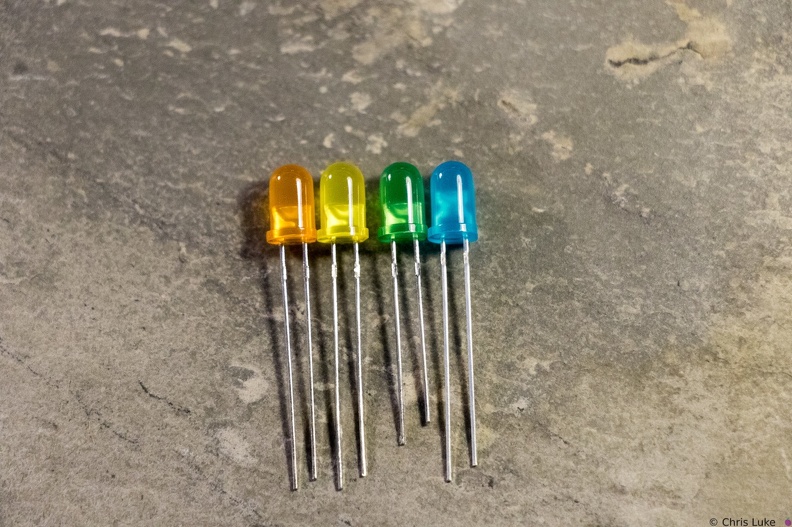

Green and blue LEDs Stockton STEM Badge LEDs and button

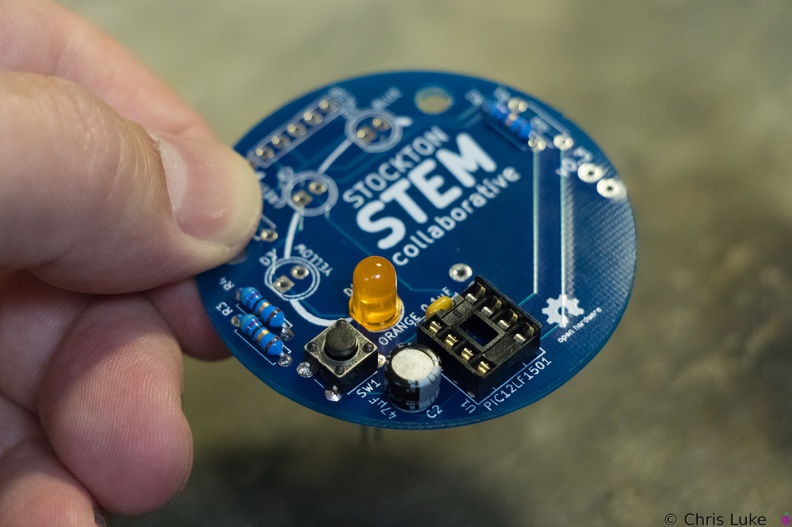

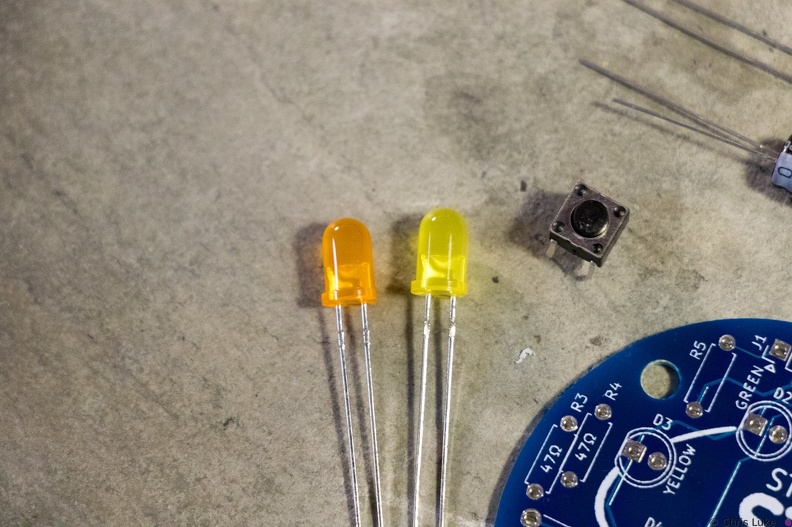

Stockton STEM Badge LEDs and button

Orange and yellow LEDS. The pushbutton switch allows a person to control the badge. Stockton STEM Badge microcontroller

Stockton STEM Badge microcontroller

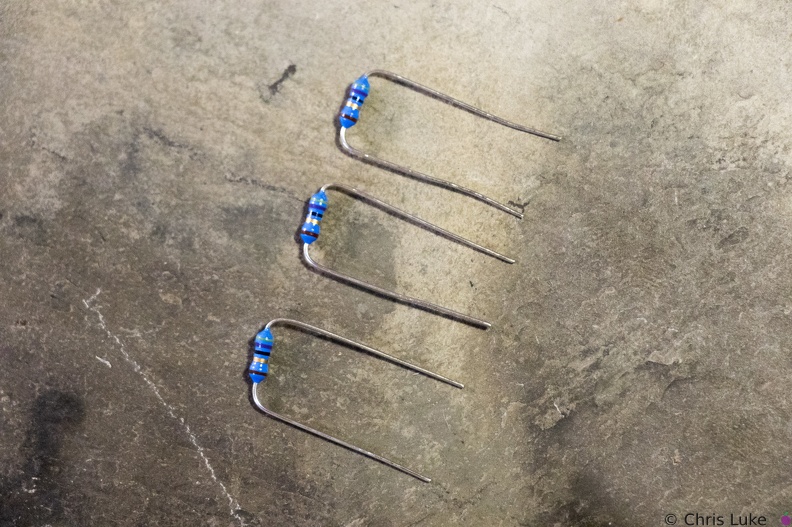

The chip is an inexpensive "PIC" microcontroller; this runs a program that controls the LEDs. Stockton STEM Badge resistor legs

Stockton STEM Badge resistor legs

The legs are trimmed, the excess removed with side-cutters. Stockton STEM Badge resistor legs

Stockton STEM Badge resistor legs

Soldered legs; only a small amount of solder is needed and it heat should be applied only briefly. Stockton STEM Badge resistor legs

Stockton STEM Badge resistor legs

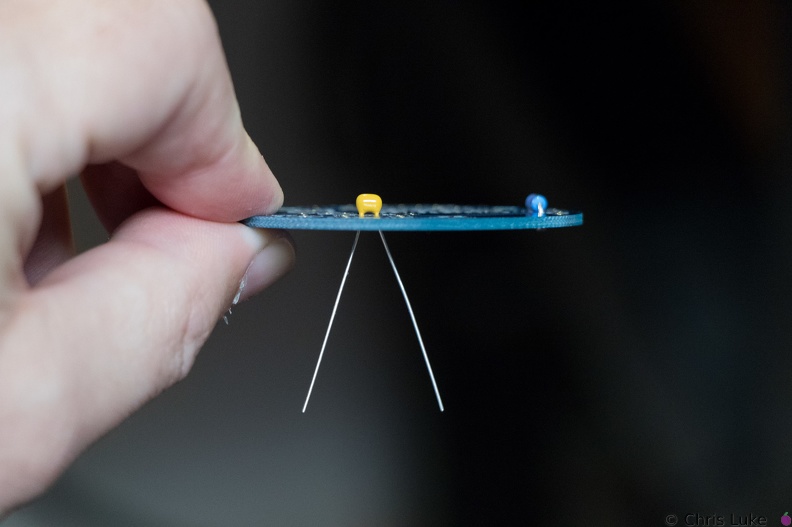

The legs are then carefully bent to about 45 degrees to hold the resistor in place for soldering. Stockton STEM Badge resistor legs

Stockton STEM Badge resistor legs

The legs are passed through the board holes; they may need pulling firmly, but not too firmly, with pliers to pull the resistor body flush with the board. Stockton STEM Badge resistor legs

Stockton STEM Badge resistor legs

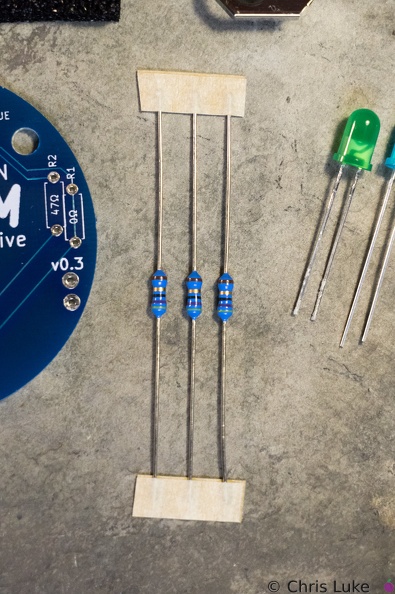

The resistor legs need to be bent in order to insert them into the board. Stockton STEM Badge resistors

Stockton STEM Badge resistors

These are 47 ohm resistors; they limit the current supplied to the orange, yellow and green LEDs. The blue LED does not require one. Taking shape

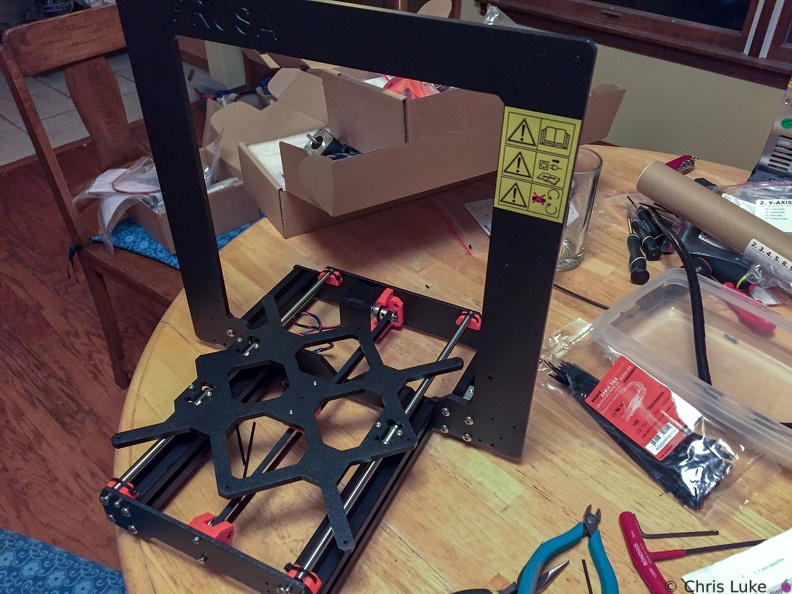

Taking shape Testing the slide of the bed

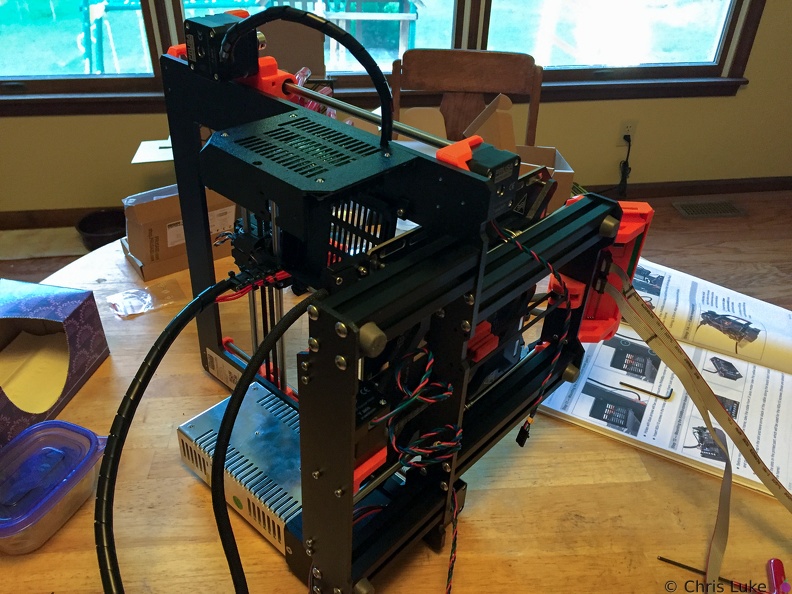

Testing the slide of the bed The cables have to go somewhere

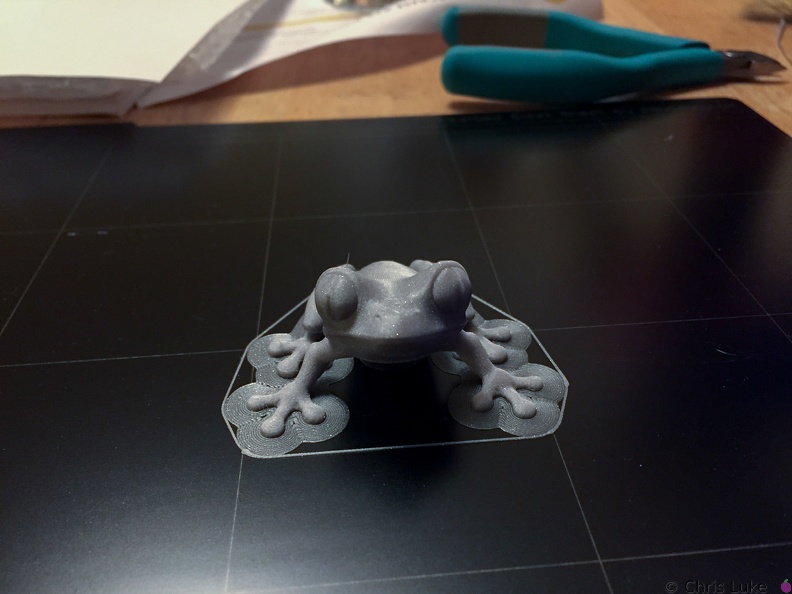

The cables have to go somewhere Treefrog

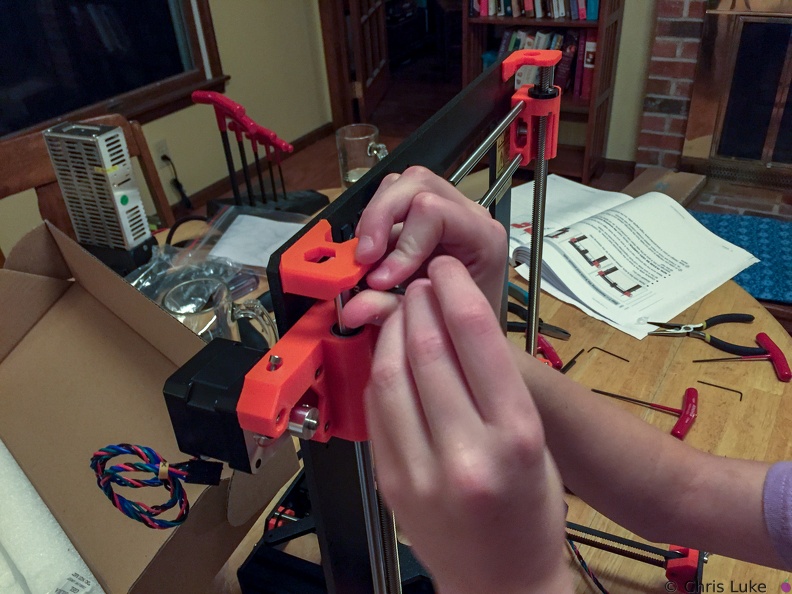

Treefrog X and Z axis

X and Z axis Y-axle idler pulley

Y-axle idler pulley Z-axis motor mounts

Z-axis motor mounts Z-axis motor mounts

Z-axis motor mounts