« Saturday

- IMG 1444

- IMG 1445

- IMG 1446

- IMG 1447

- IMG 1448

- IMG 4054

- IMG 4055

- IMG 4056

- IMG 4057

- IMG 4058

- IMG 4064

- IMG 4070

- IMG 4071

- IMG 4072

- IMG 4077

- IMG 4078

- IMG 4080

- IMG 4081

- IMG 4086

- IMG 4087

- IMG 4088

- IMG 4091

- IMG 4092

- IMG 4093

- IMG 4094

- IMG 4095

- IMG 4096

- IMG 4097

- IMG 4099

- IMG 4101

- IMG 4102

- IMG 5336

- IMG 5338

- IMG 5342

- IMG 5344

- IMG 5351

- IMG 5352

- IMG 8095

- IMG 8096

- IMG 8097

- IMG 8098

- IMG 8099

- IMG 8100

- IMG 8101

- IMG 8102

- IMG 8104

- IMG 8106

- IMG 8107

- IMG 8108

- IMG 8109

- 2015-01-17 001

- 2015-01-17 002

- 2015-01-17 003

- 2015-01-17 004

- 2015-01-17 005

- 2015-01-17 006

- 2015-01-17 007

- 2015-01-17 008

- 2015-01-17 009

- 2015-01-17 010

- 2015-01-17 011

- 2015-01-17 015

- 2015-01-17 016

- 2015-01-17 017

- 2015-01-25 001

- 2015-01-25 002

- 2015-01-25 003

- 2015-01-25 004

- 2015-01-25 005

- 2015-01-25 006

- 2015-01-25 007

- 2015-01-25 009

- 2015-01-25 010

- 2015-01-25 011

- 2015-01-25 012

- 2015-01-25 013

- 2015-01-25 014

- 2015-01-25 015

- 2015-01-25 016

- 2015-01-25 017

- 2015-01-25 018

- 2015-01-25 019

- 2015-01-25 020

- 2015-01-25 021

- 2015-01-26 001

- 2015-01-26 002

- 2015-01-26 003

- 2015-01-26 004

- 2015-01-26 005

- 2015-01-26 006

- 2015-01-26 007

- 2015-01-26 008

- 2015-01-26 009

- 2015-01-26 010

- 2015-01-26 011

- 2015-01-26 012

- 2015-01-26 014

- 2015-01-26 015

- 2015-01-26 016

- 2015-01-26 017

- 2015-01-27 001

- 2015-01-27 002

- 2015-01-27 003

- 2015-01-27 004

- 2015-01-27 005

- 2015-01-27 006

- 2015-01-27 007

- 2015-01-27 008

- 2015-01-27 009

- 2015-01-27 010

- 2015-01-27 011

- 2015-01-27 012

- 2015-02-01 003

- 2015-02-01 004

- 2015-02-01 005

- 2015-02-01 006

- 2015-02-01 007

- 2015-02-01 008

- 2015-02-01 009

- 2015-02-01 010

- 2015-02-02 001

- 2015-02-02 002

- 2015-02-02 003

- 2015-02-02 004

- 2015-02-04 001

- 2015-02-05 001

- 2015-02-05 002

- 2015-02-05 004

- 2015-02-06 001

- 2015-02-06 003

- 2015-02-06 005

- 2015-02-06 006

- IMG 5853

- IMG 5854

- IMG 5859

- IMG 5860

- IMG 5862

- IMG 5865

- IMG 5869

- IMG 5871

- IMG 5873

- IMG 5874

- IMG 5875

- IMG 5876

- IMG 5879

- IMG 5880

- IMG 5881

- IMG 5882

- IMG 5883

- IMG 5884

- IMG 5888

- IMG 5890

- IMG 5891

- IMG 5892

- IMG 5904

- IMG 5907

- IMG 5908

- grbl

The grbl controller; underneath this stepper driver is an Arduino Uno and a breakout board. - IMG 5909

- IMG 5910

- IMG 5912

- IMG 5914

- IMG 5915

- IMG 5917

- IMG 5919

- IMG 5921

- IMG 5922

- IMG 5923

- IMG 5924

- IMG 5925

- IMG 5926

- IMG 5927

- IMG 5928

- IMG 5931

- IMG 5932

- IMG 5933

- IMG 5934

- IMG 5935

- IMG 5936

- IMG 5937

- IMG 5938

- IMG 5939

- IMG 5940

- IMG 5941

- IMG 5943

- IMG 5944

- IMG 5945

- IMG 5946

- IMG 6000

- IMG 6001

- IMG 6002

IMG 4482

IMG 4482- 3C2A3239

- 3C2A3249

- 3C2A3251

- 3C2A3261

- 3C2A3266

- 3C2A3279

- 3C2A3282

- 3C2A3284

- 3C2A3288

- 3C2A3290

- 3C2A3292

- 3C2A3294

- 3C2A3295

- 3C2A3297

- 3C2A3300

- 3C2A3304

- 3C2A3306

- 3C2A3309

- 3C2A3318

- 3C2A3324

- 3C2A3330

- 3C2A3331

- 3C2A3332

- 3C2A3341

3C2A4590

3C2A4590 3C2A4663

3C2A4663 3C2A4771

3C2A4771 3C2A4821

3C2A4821 3C2A4856

3C2A4856 3C2A4857

3C2A4857 3C2A4863

3C2A4863 3C2A4865

3C2A4865 3C2A4866

3C2A4866 3C2A4869

3C2A4869 3C2A4871

3C2A4871 Merlin's Cave

Merlin's Cave 3C2A4876

3C2A4876 3C2A4877

3C2A4877 3C2A4887

3C2A4887 3C2A4889

3C2A4889 3C2A4893

3C2A4893 3C2A4900

3C2A4900 3C2A4903

3C2A4903 3C2A4904

3C2A4904 3C2A4906

3C2A4906 3C2A4912

3C2A4912 3C2A4919

3C2A4919 3C2A4920

3C2A4920 3C2A4929

3C2A4929 3C2A4969

3C2A4969 3C2A4971

3C2A4971 3C2A4973

3C2A4973 3C2A4974

3C2A4974 3C2A4975

3C2A4975 3C2A4976

3C2A4976 3C2A4978

3C2A4978 3C2A4991

3C2A4991 3C2A4992

3C2A4992 3C2A4995

3C2A4995 3C2A5001

3C2A5001 3C2A5006

3C2A5006 3C2A5007

3C2A5007 3C2A5008

3C2A5008 3C2A5021

3C2A5021 3C2A5023

3C2A5023 3C2A5026

3C2A5026 3C2A5030

3C2A5030 3C2A5036

3C2A5036 3C2A5040

3C2A5040 3C2A5050

3C2A5050 3C2A5076

3C2A5076 3C2A5086

3C2A5086 3C2A5106

3C2A5106 3C2A5108

3C2A5108 3C2A5118

3C2A5118 3C2A5123

3C2A5123 3C2A5179

3C2A5179 3C2A5183

3C2A5183 3C2A5193

3C2A5193 3C2A5202

3C2A5202 3C2A5209

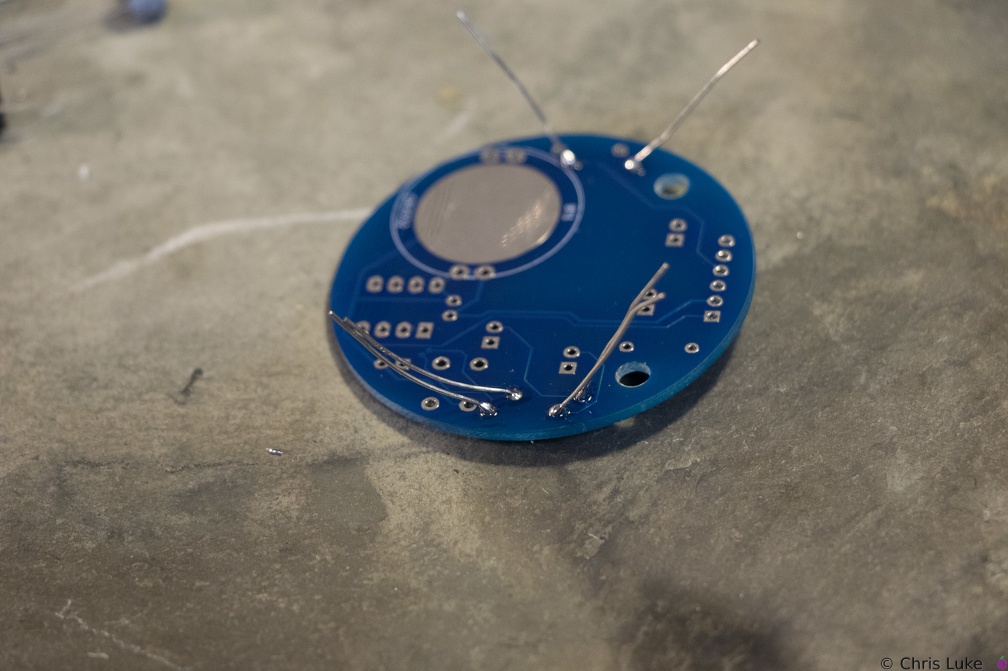

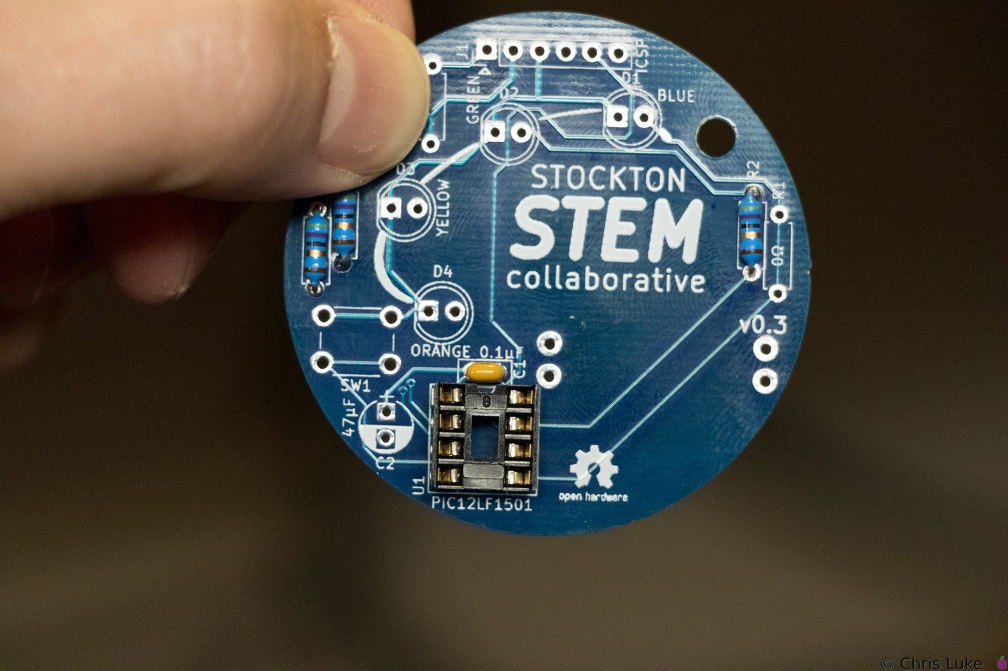

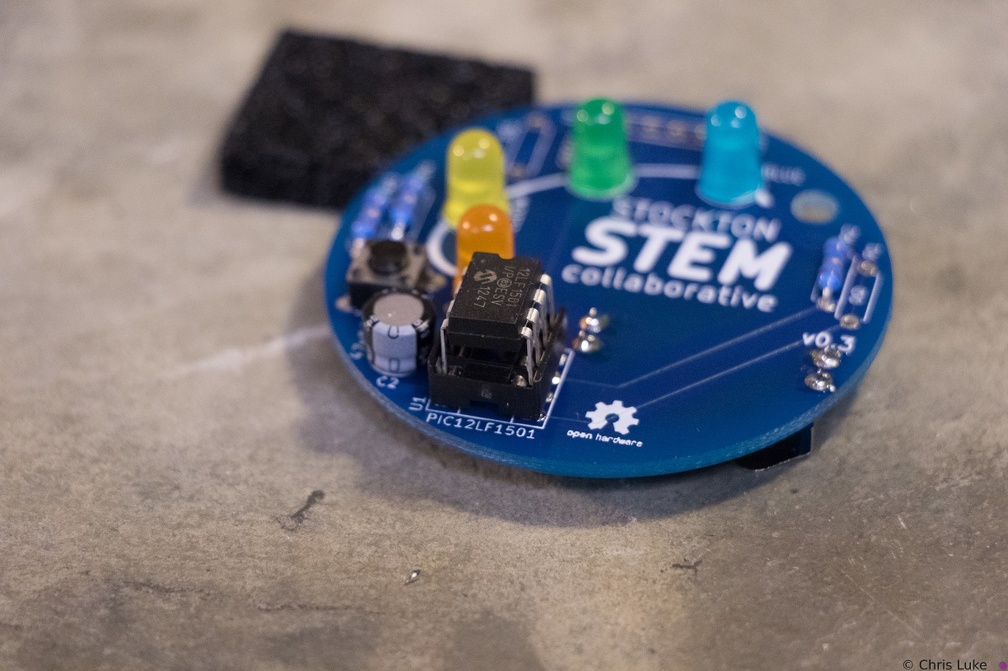

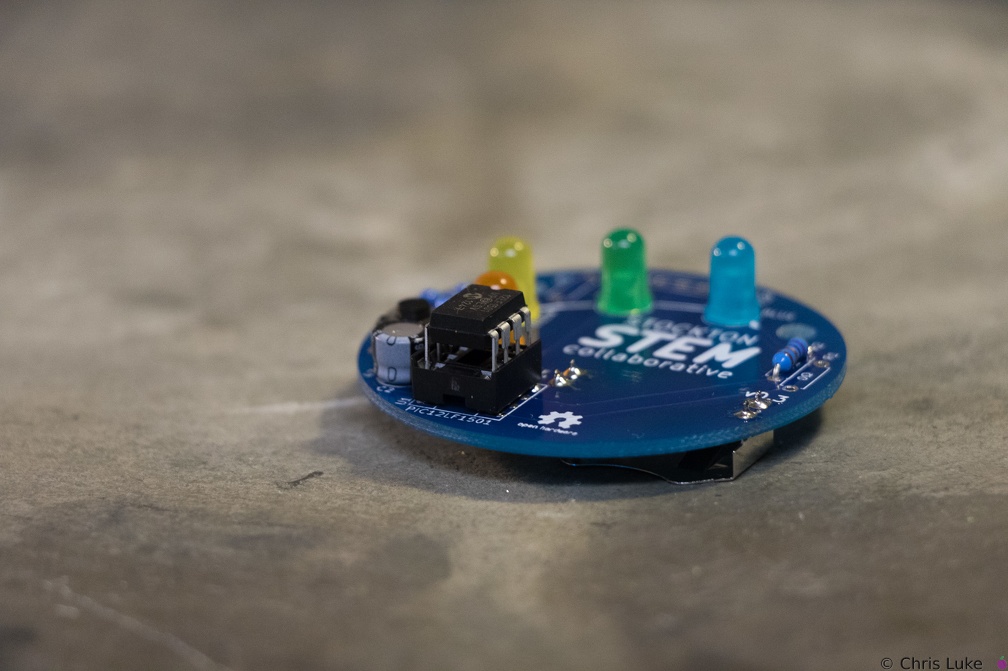

3C2A5209 Stockton STEM Badge boards

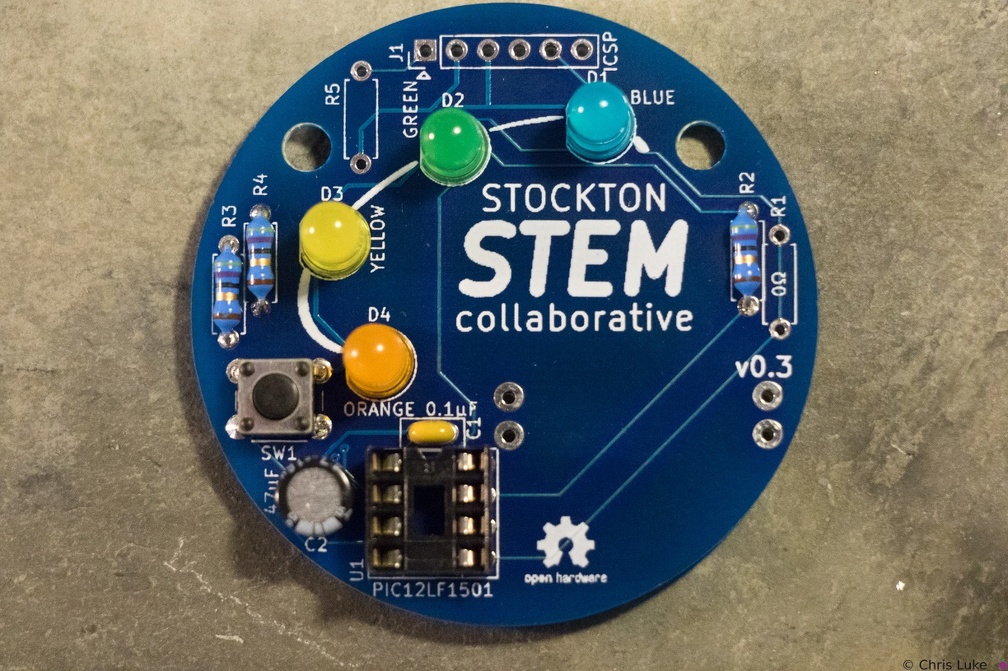

Stockton STEM Badge boards

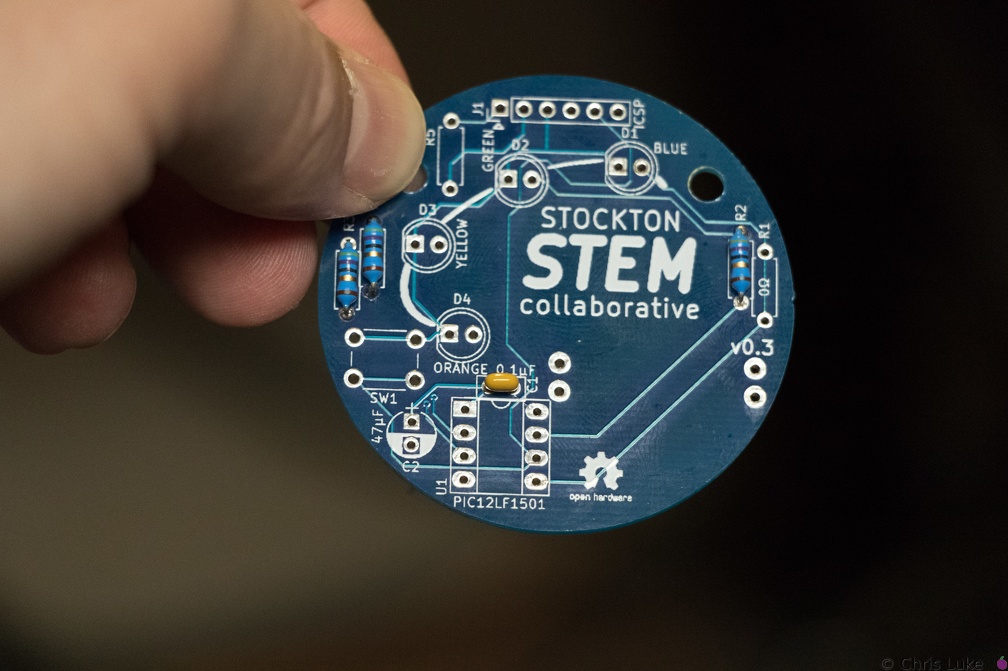

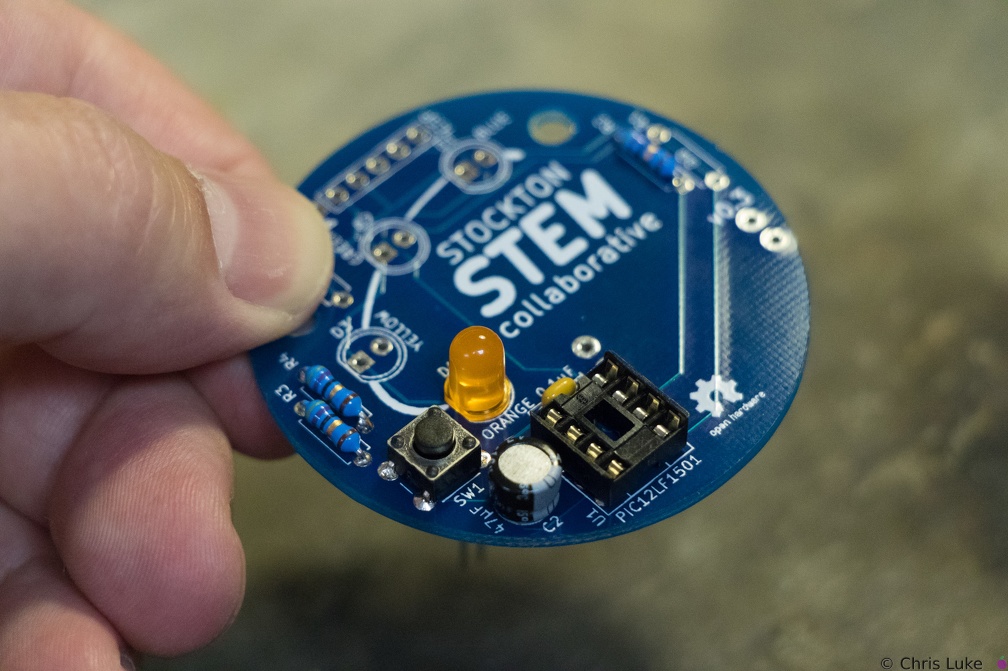

The badge printed circuit board (PCB) comes in several colors. Stockton STEM Badge components

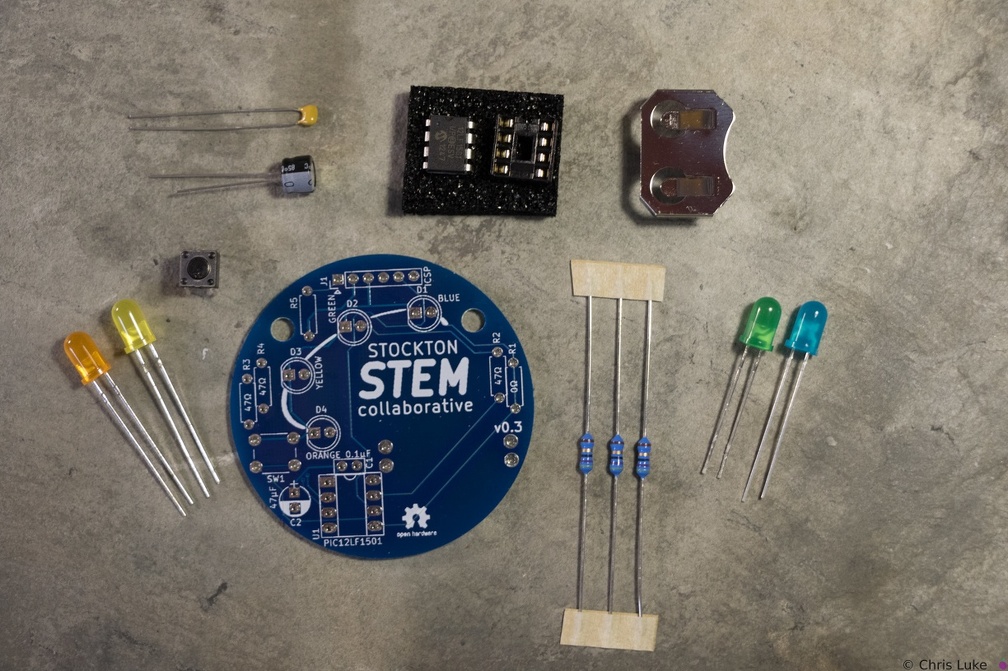

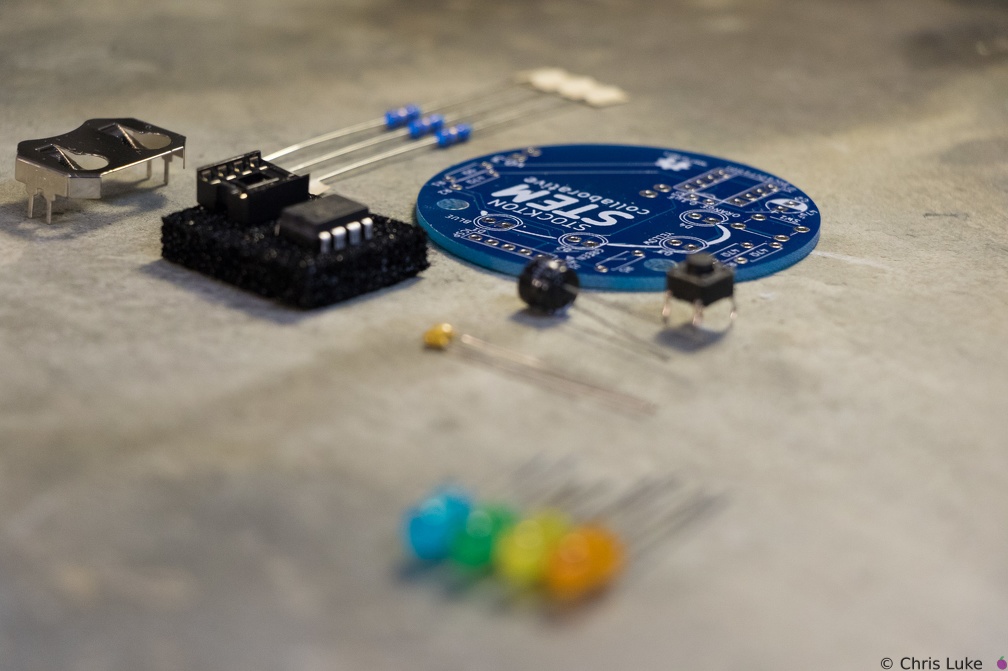

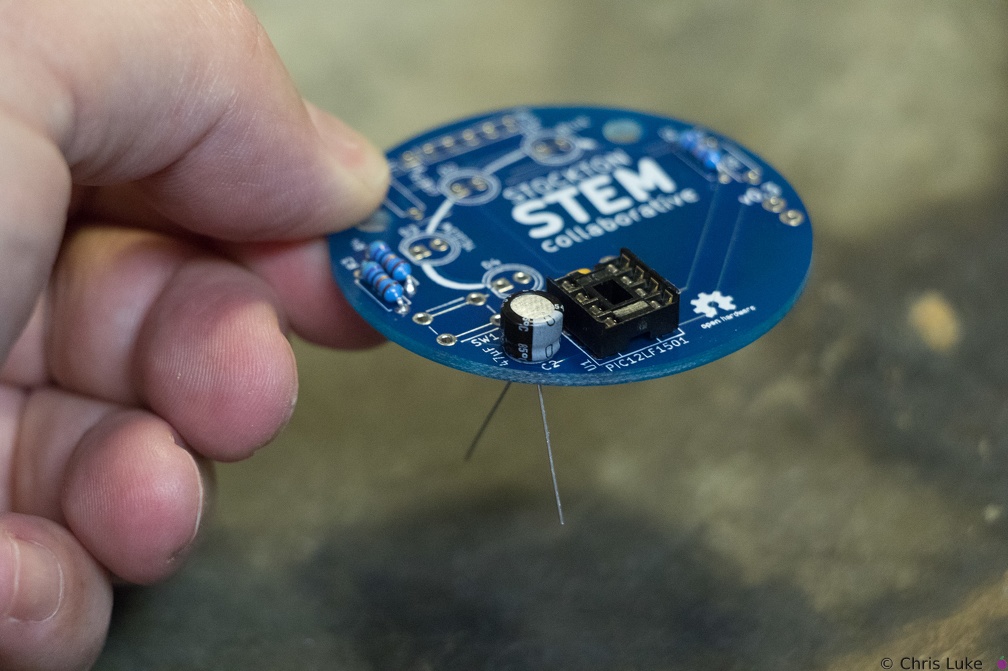

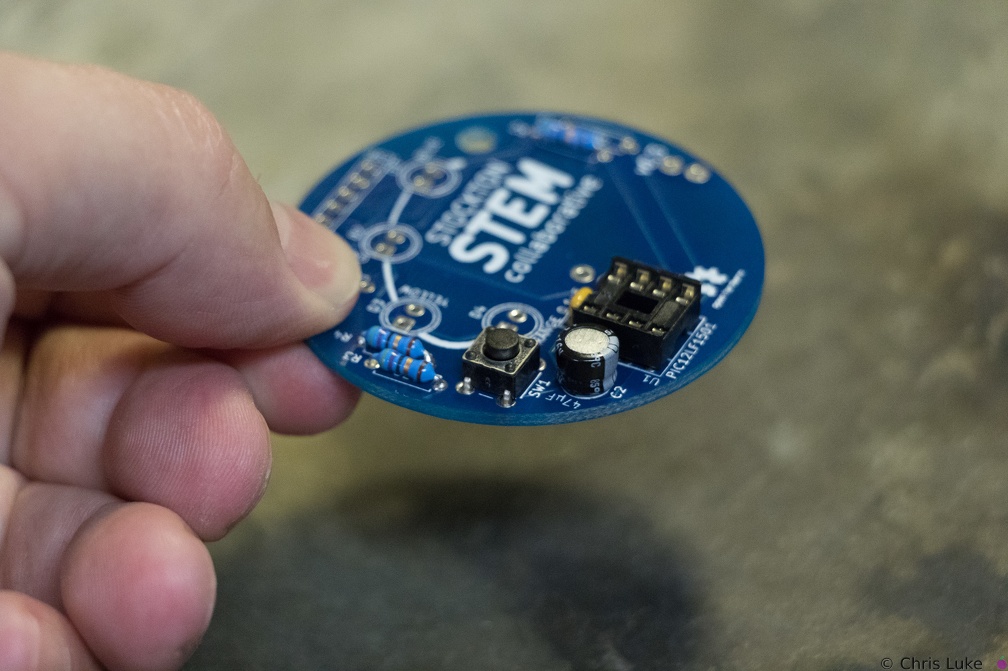

Stockton STEM Badge components

The badge consists of a handful of electronic components. Components R1, R5 and J1 are not normally populated. Stockton STEM Badge microcontroller

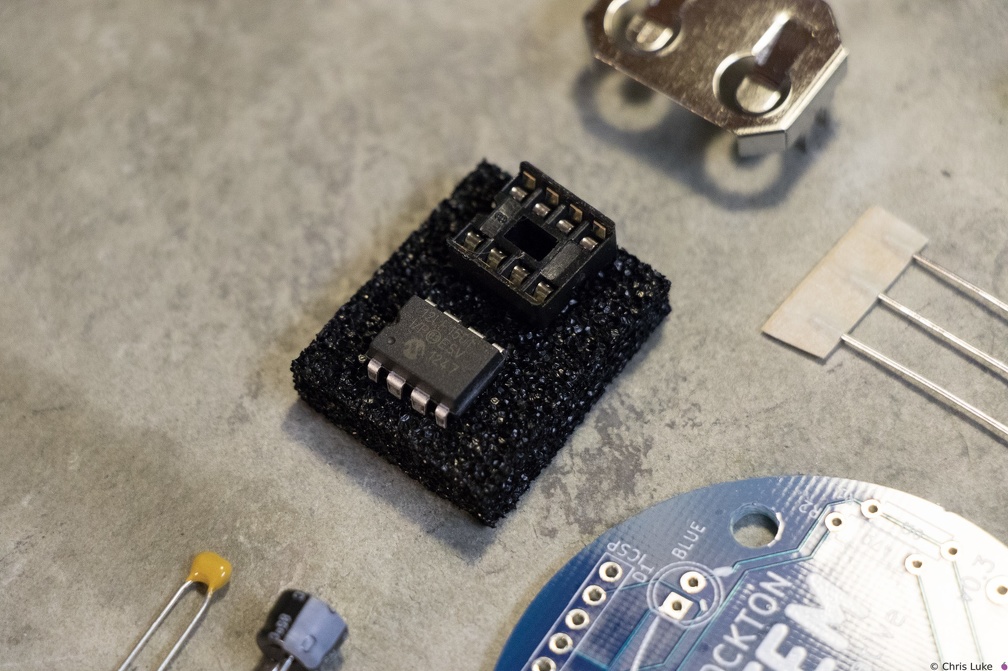

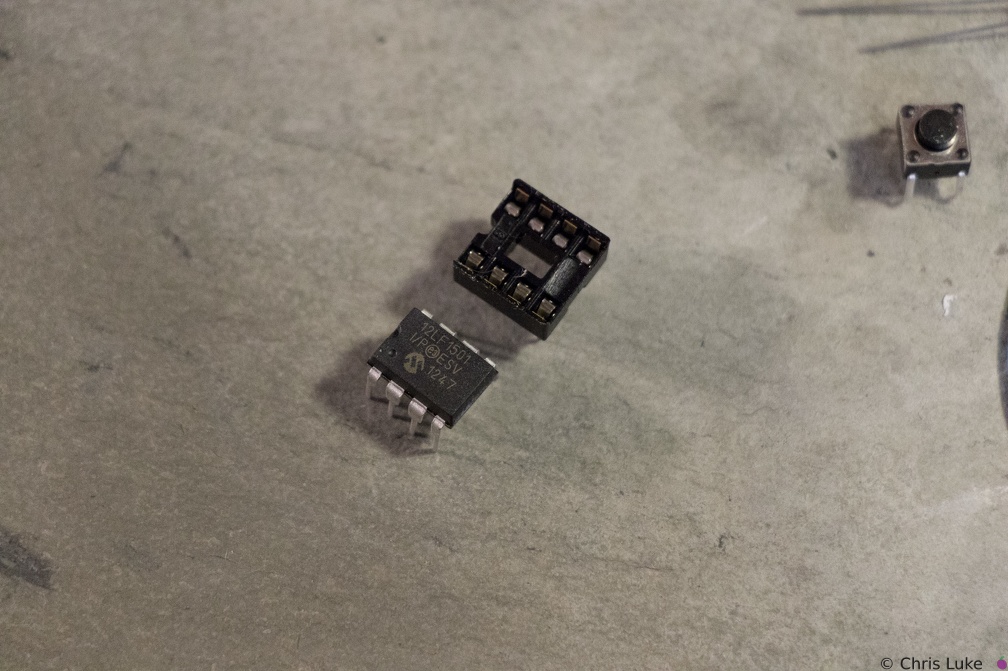

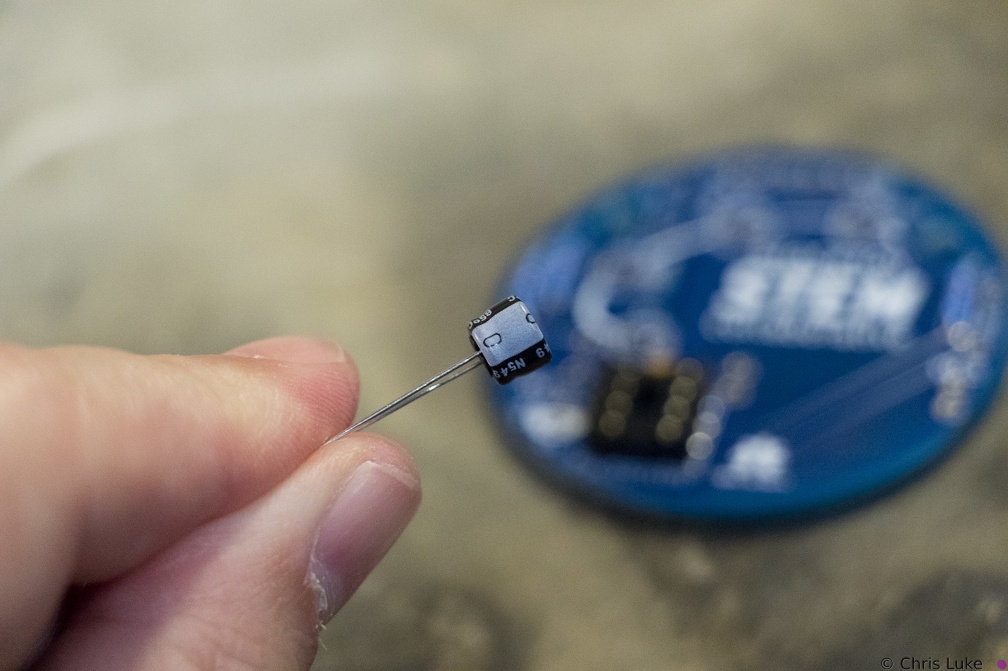

Stockton STEM Badge microcontroller

The chip is an inexpensive "PIC" microcontroller; this runs a program that controls the LEDs. Stockton STEM Badge resistors

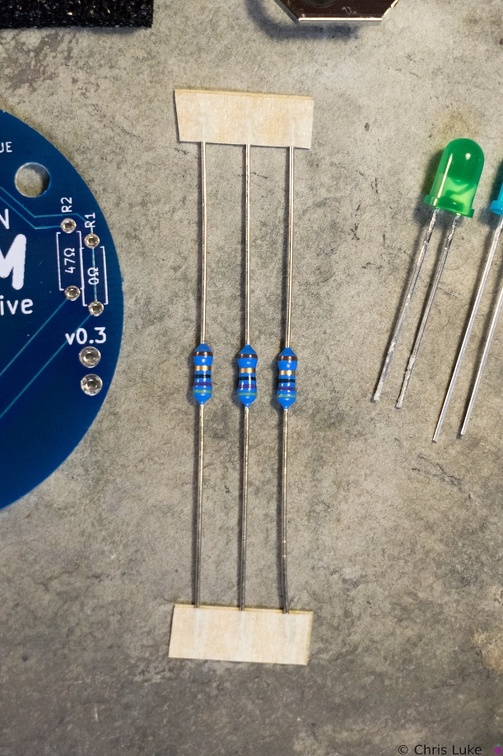

Stockton STEM Badge resistors

These are 47 ohm resistors; they limit the current supplied to the orange, yellow and green LEDs. The blue LED does not require one. Stockton STEM Badge capacitors

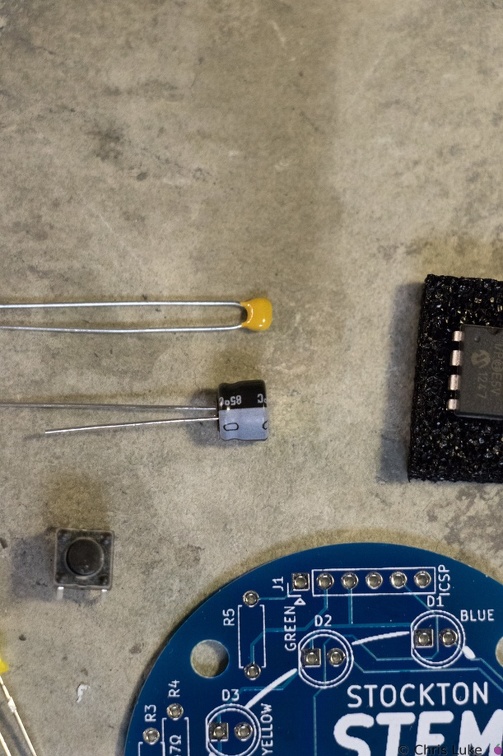

Stockton STEM Badge capacitors

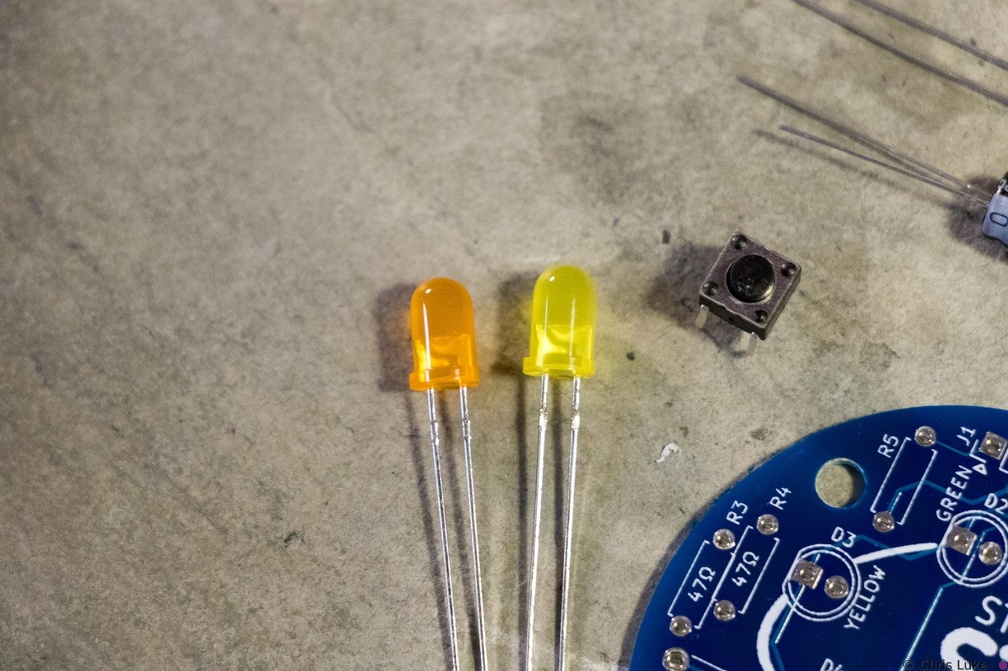

The capacitors smooth the power on the badge. The top capacitor, is not polarity sensitive; that is, it can be used either way round. The other capacitor must be used only the correct way round; the case has a "-" symbol printed on it. Stockton STEM Badge LEDs and button

Stockton STEM Badge LEDs and button

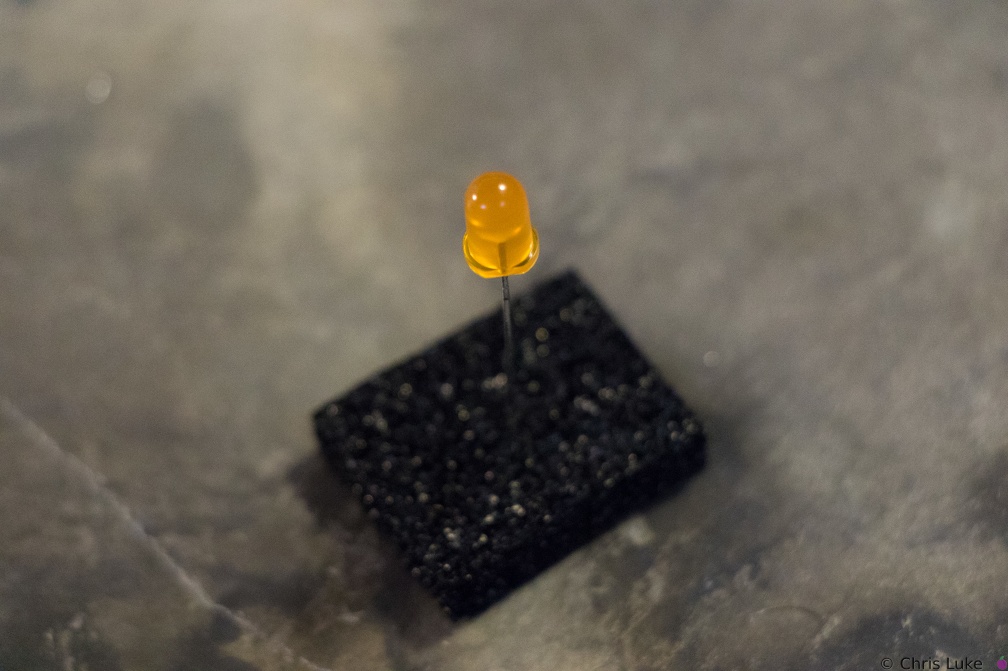

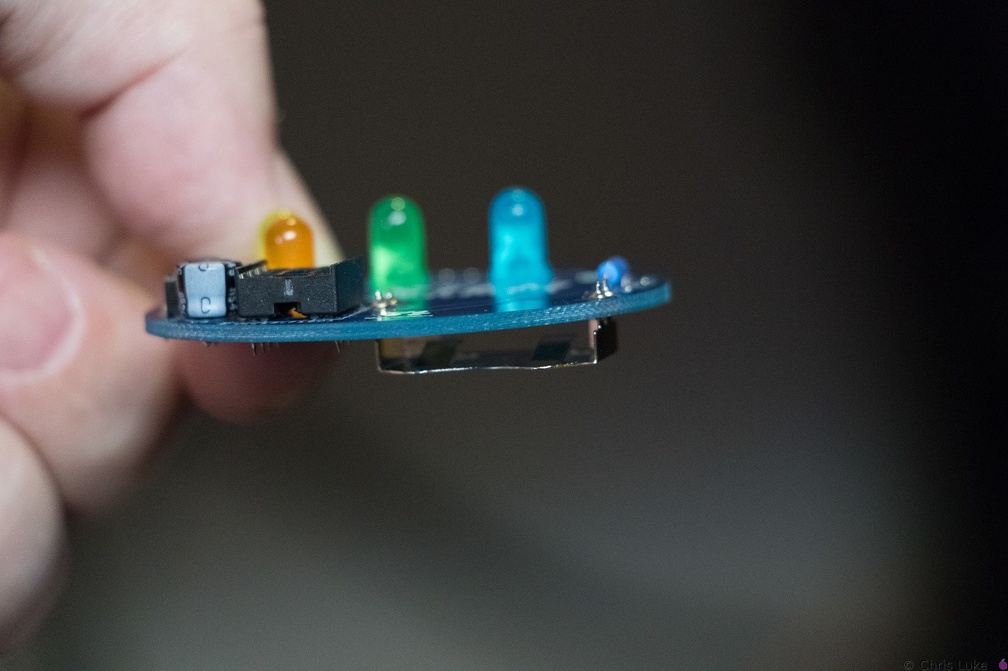

Orange and yellow LEDS. The pushbutton switch allows a person to control the badge. Stockton STEM Badge LEDs

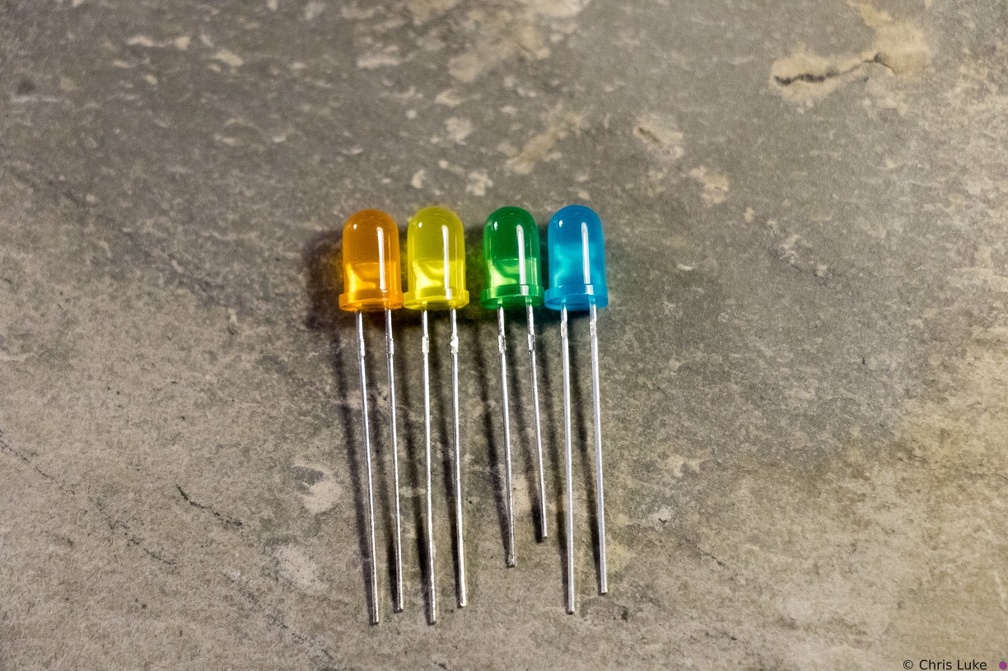

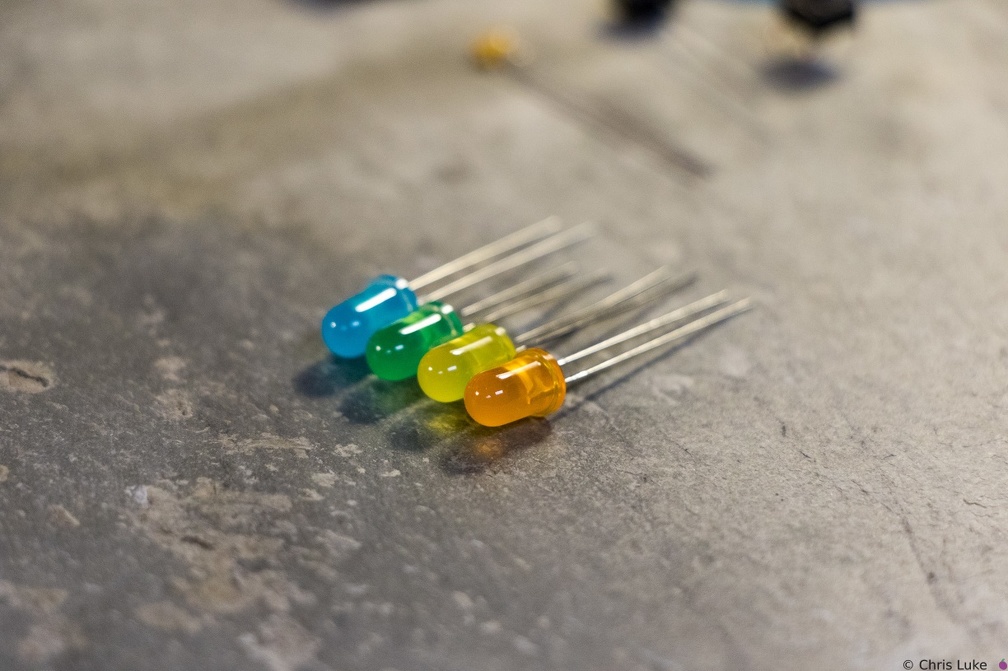

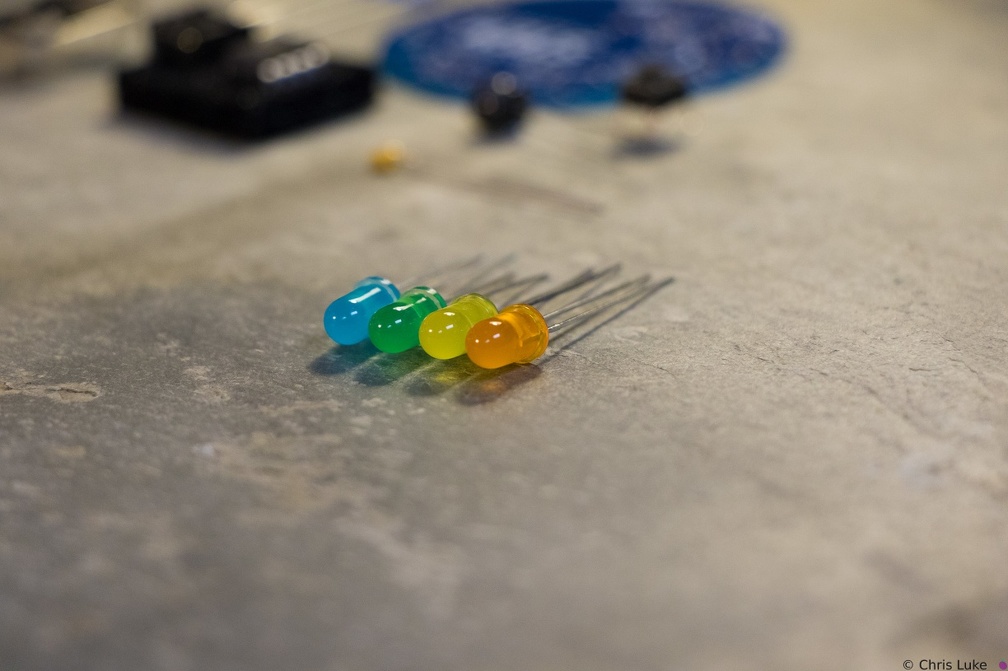

Stockton STEM Badge LEDs

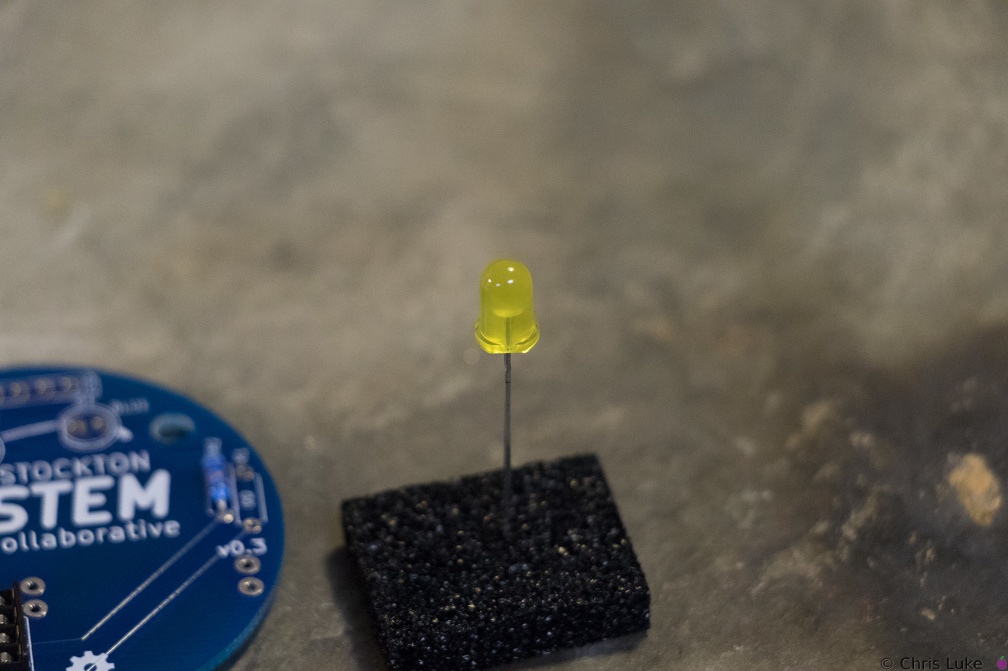

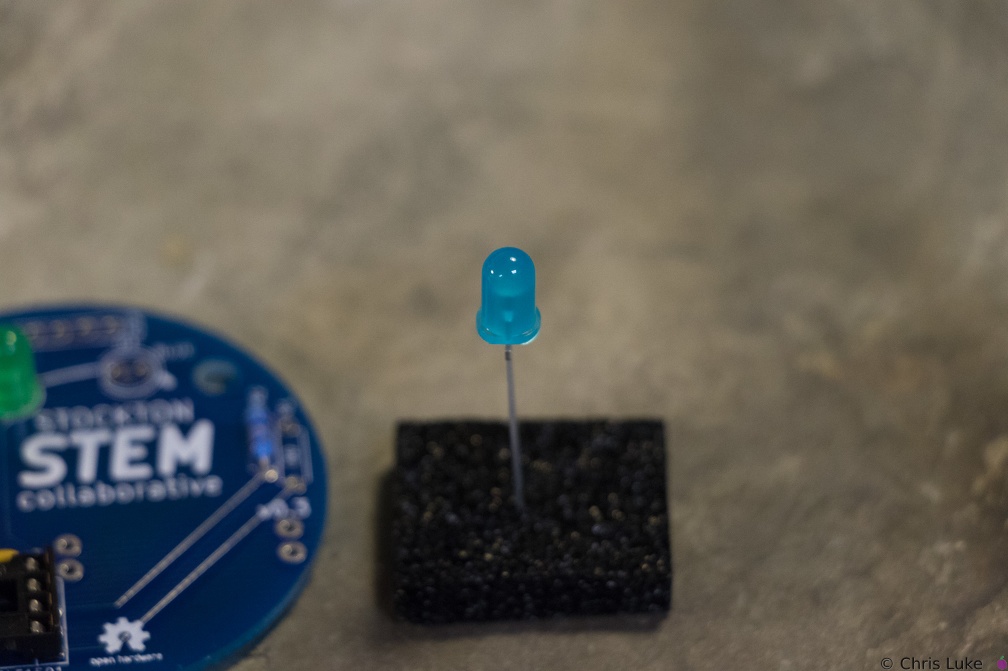

Green and blue LEDs Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

Notice how the LEDs typically have one leg longer than the other; this is called the "anode". The colored case also has one flat side, opposite the longer leg; the leg on this side is called the "cathode". Also, note the distinctive shape of what is inside the colored case; this can also be used to help determine its orientation. The gap at the top of the metal surface is always on the anode side. LEDs can only be used the right way round so determining orientation is important. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs Stockton STEM Badge LEDs

Stockton STEM Badge LEDs Stockton STEM Badge components

Stockton STEM Badge components Stockton STEM Badge IC and socket

Stockton STEM Badge IC and socket

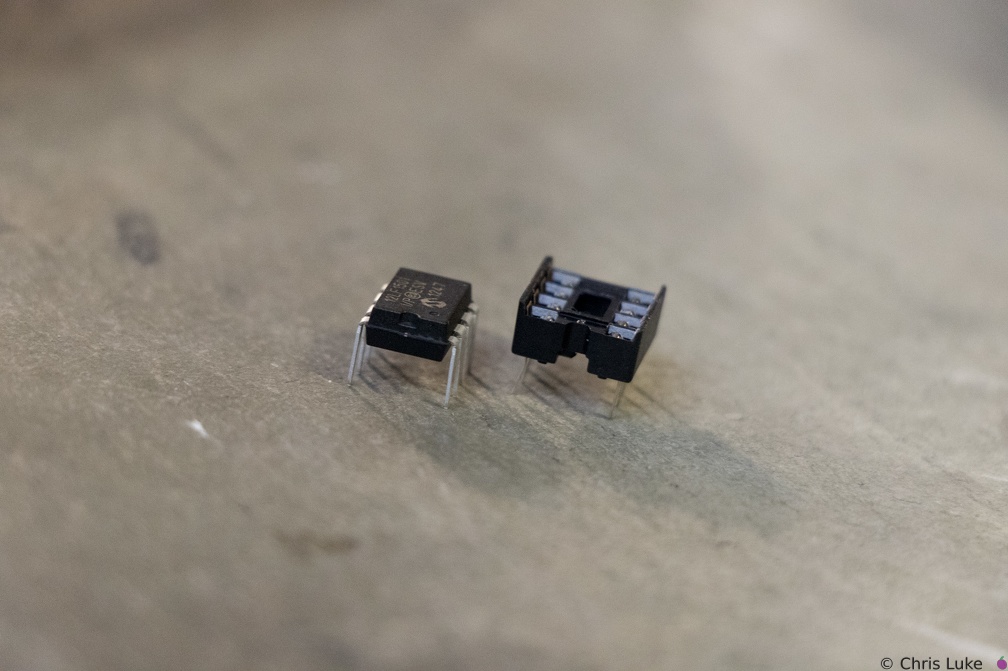

The chip, an integrated circuit, or IC, must also be used the correct way round. Both the chip and its socket have a notch at one end to identify its orientation. Stockton STEM Badge IC and socket

Stockton STEM Badge IC and socket

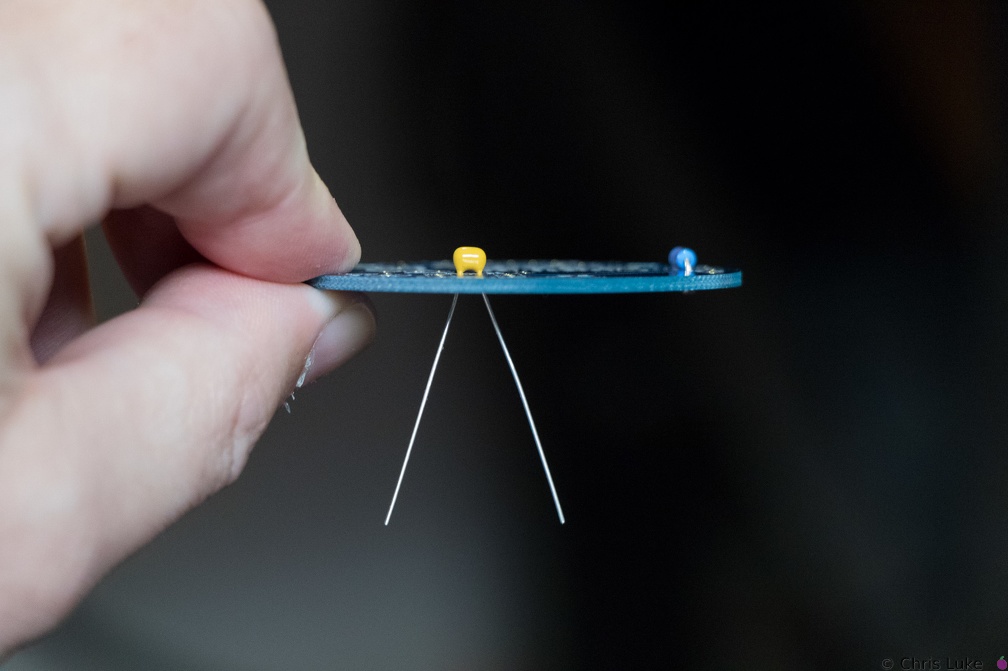

The legs of the chip need to be straight otherwise they will not properly insert into their positions in the socket. It is easy to bend or break the legs if care is not taken. Stockton STEM Badge resistor legs

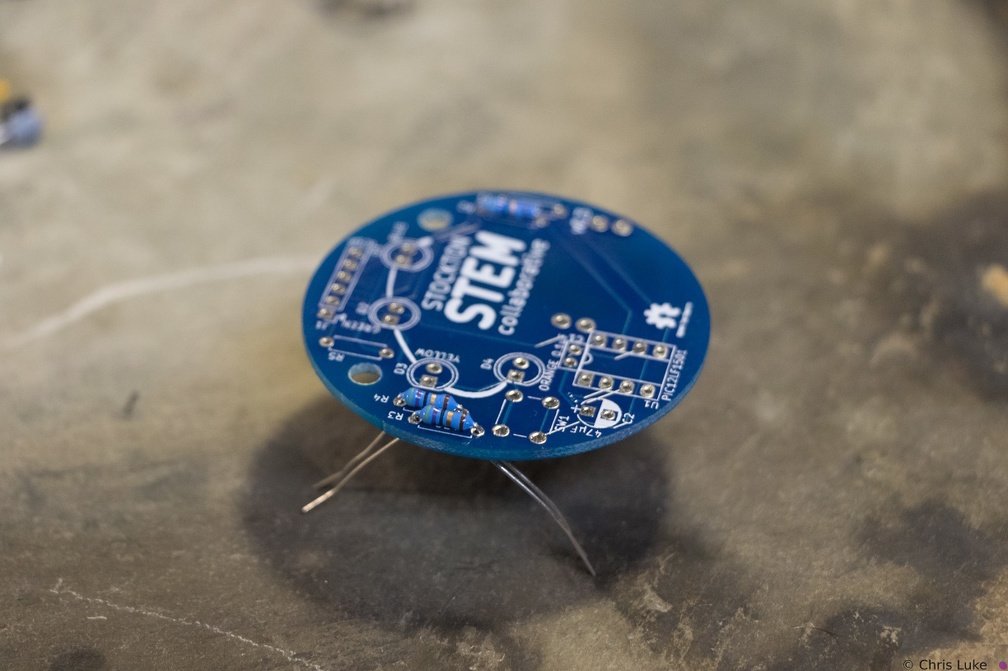

Stockton STEM Badge resistor legs

The resistor legs need to be bent in order to insert them into the board. Stockton STEM Badge resistor legs

Stockton STEM Badge resistor legs

The legs are passed through the board holes; they may need pulling firmly, but not too firmly, with pliers to pull the resistor body flush with the board. Stockton STEM Badge resistor legs

Stockton STEM Badge resistor legs

The legs are then carefully bent to about 45 degrees to hold the resistor in place for soldering. Stockton STEM Badge resistor legs

Stockton STEM Badge resistor legs

Soldered legs; only a small amount of solder is needed and it heat should be applied only briefly. Stockton STEM Badge resistor legs

Stockton STEM Badge resistor legs

The legs are trimmed, the excess removed with side-cutters. Stockton STEM Badge decoupling capacitor

Stockton STEM Badge decoupling capacitor

This ceramic capacitor is not orientation sensitive. Decoupling means it absorbs electrical noise and is used to filter the power feeding the microcontroller. Stockton STEM Badge decoupling capacitor

Stockton STEM Badge decoupling capacitor

The capacitor should sit flush with the board. Stockton STEM Badge decoupling capacitor

Stockton STEM Badge decoupling capacitor

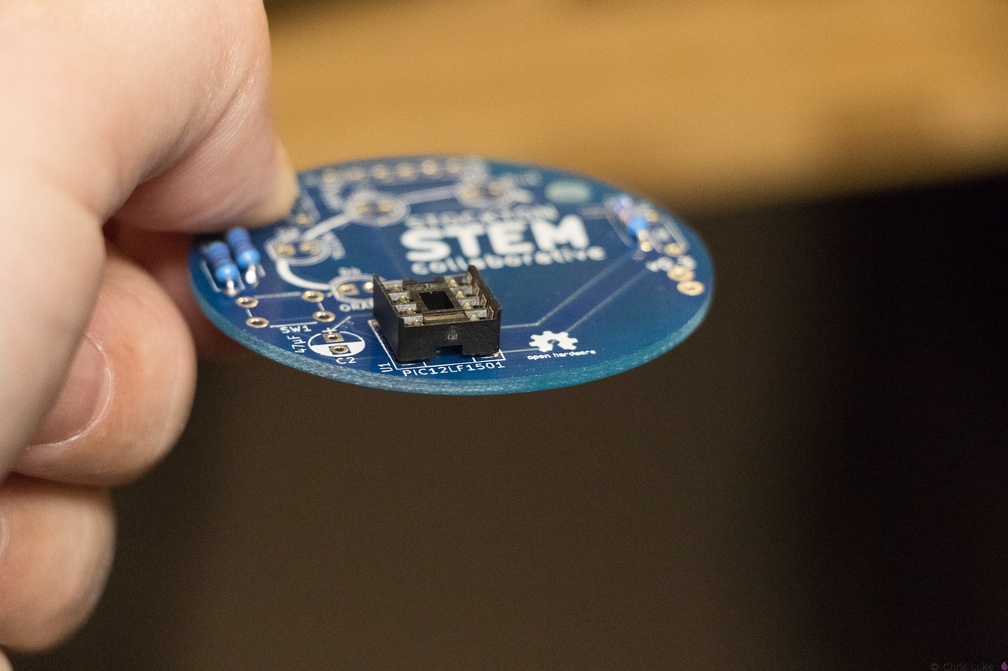

As with the resistors, the legs should be splayed a little to help hold it in place for soldering. Stockton STEM Badge IC socket

Stockton STEM Badge IC socket

Note the orientation of the indent at the upper edge of the IC socket. Stockton STEM Badge IC socket

Stockton STEM Badge IC socket

The IC socket should lay flat against the board. Stockton STEM Badge IC socket

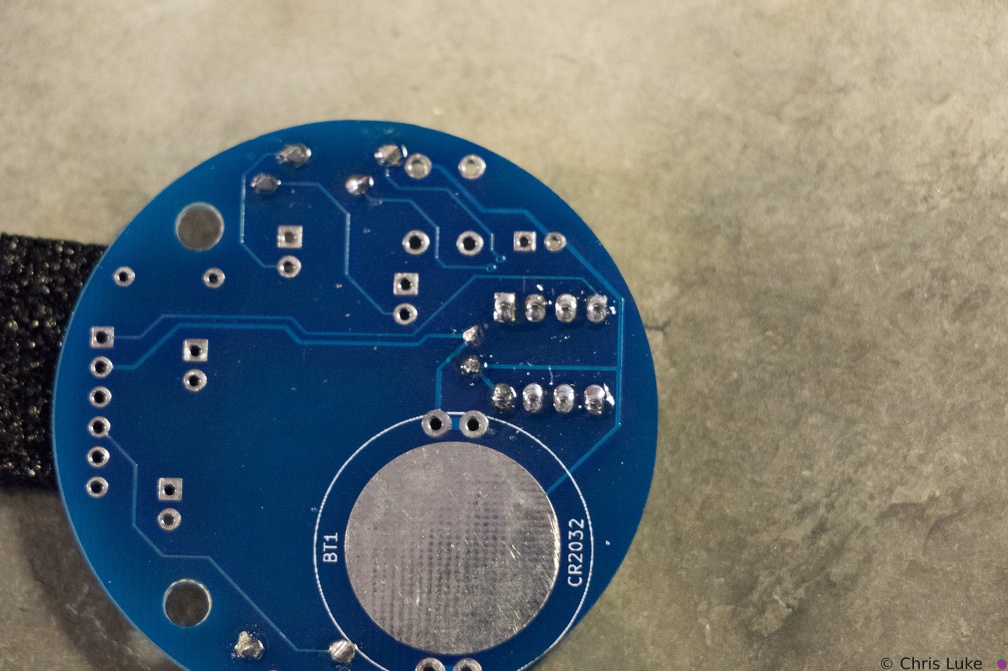

Stockton STEM Badge IC socket

Soldering one leg first and checking that the socket is flat against the board avoids a simple mistake. If it is not flat, or otherwise misaligned simply re-heating the leg will help correct the issue. Once orientation and alignment is verified, solder the remaining legs. Sometimes a small shim, such as the black foam here, can help keep the board level and simplifies the task. Stockton STEM Badge IC socket

Stockton STEM Badge IC socket

Soldered legs. Stockton STEM Badge electrolytic capacitor

Stockton STEM Badge electrolytic capacitor

Electrolytic capacitors are polarity sensitive; note the "-" symbol on one side of the capacitor package. These capacitors typically have a larger capacity than their ceramic counterparts and are used for bulk storage; this one is used to assist the battery when the LEDs turn on. This is necessary because button cell batteries are not designed to provide as much power as the LEDs can demand. Stockton STEM Badge electrolytic capacitor

Stockton STEM Badge electrolytic capacitor

Orientation of this capacitor is important. There is a "+" symbol in the footprint of the component printed on the board; the "-" of the capacitor should be on the opposite side. Stockton STEM Badge button

Stockton STEM Badge button

The push-button switch will fit two ways. Orientation does not matter. Stockton STEM Badge button

Stockton STEM Badge button

As with the IC socket, soldering one leg first and verifying component alignment will help prevent easy mistakes. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

LEDs have a flat edge on one side of their case. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

The footprint for the LEDs also shows a flat edge; orientation of the LEDs needs to match that of the board. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

While all components can be destroyed with an excess of heat during soldering, LEDs are especially susceptible to this. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

The case of an LED can crack if the legs are bent too close to it; even after placing the LED on the board, only bend the legs slightly to hold it in place. Stockton STEM Badge LEDs

Stockton STEM Badge LEDs

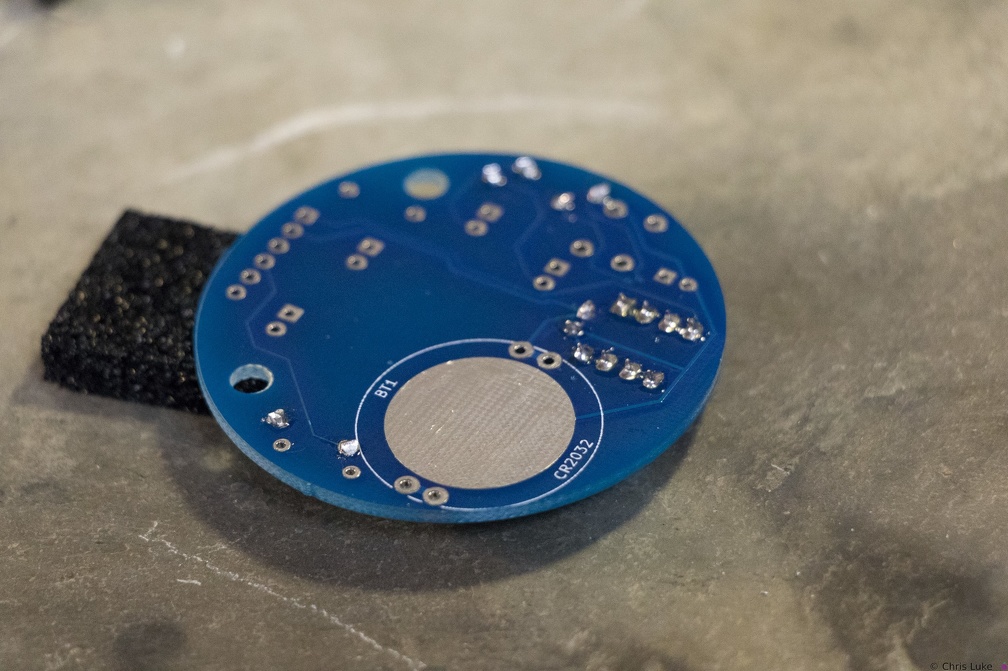

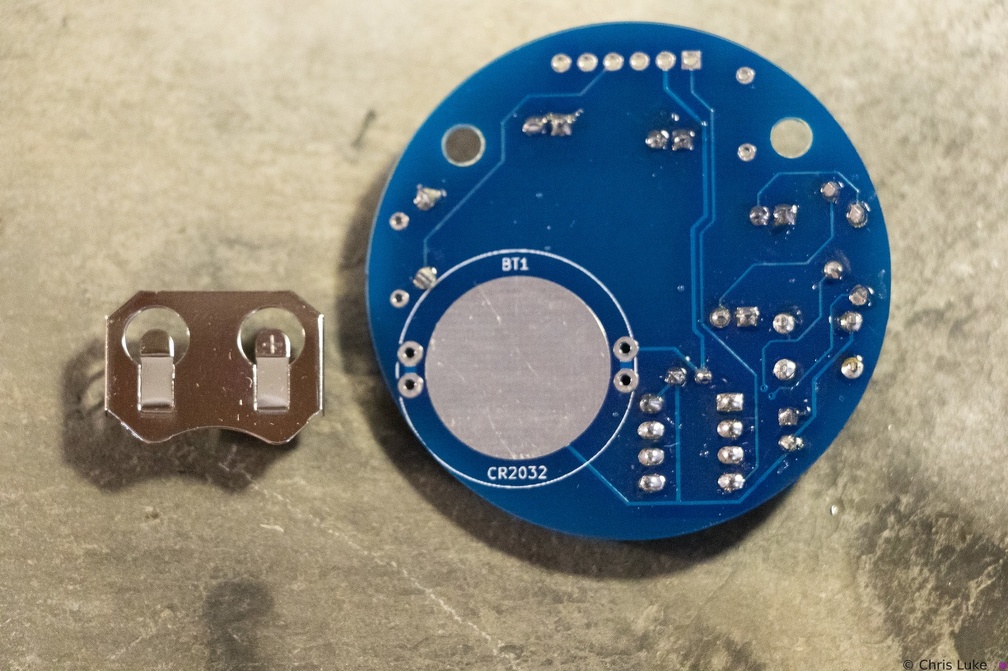

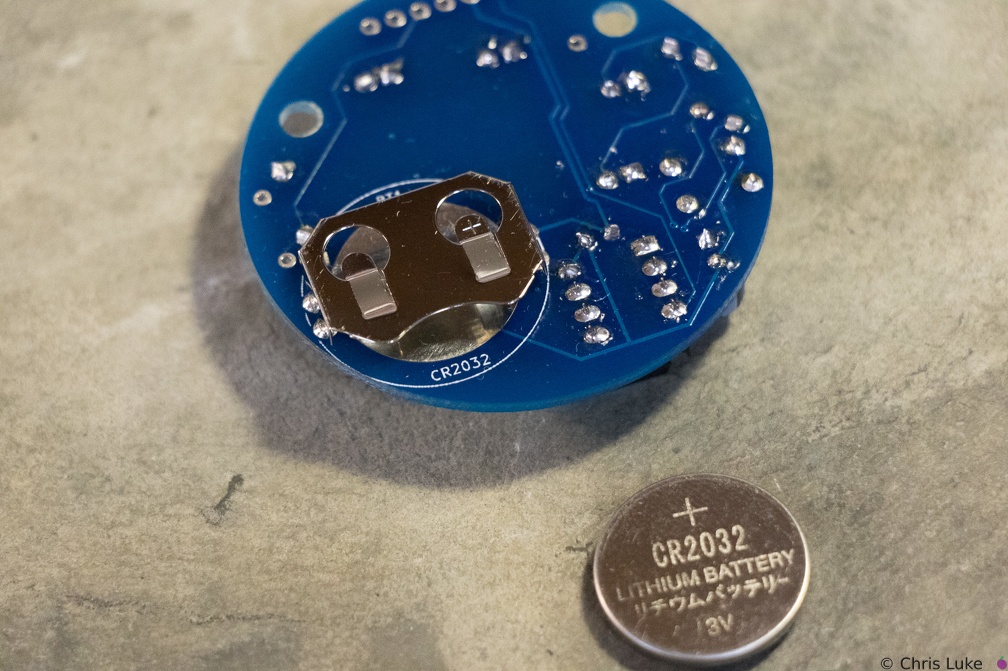

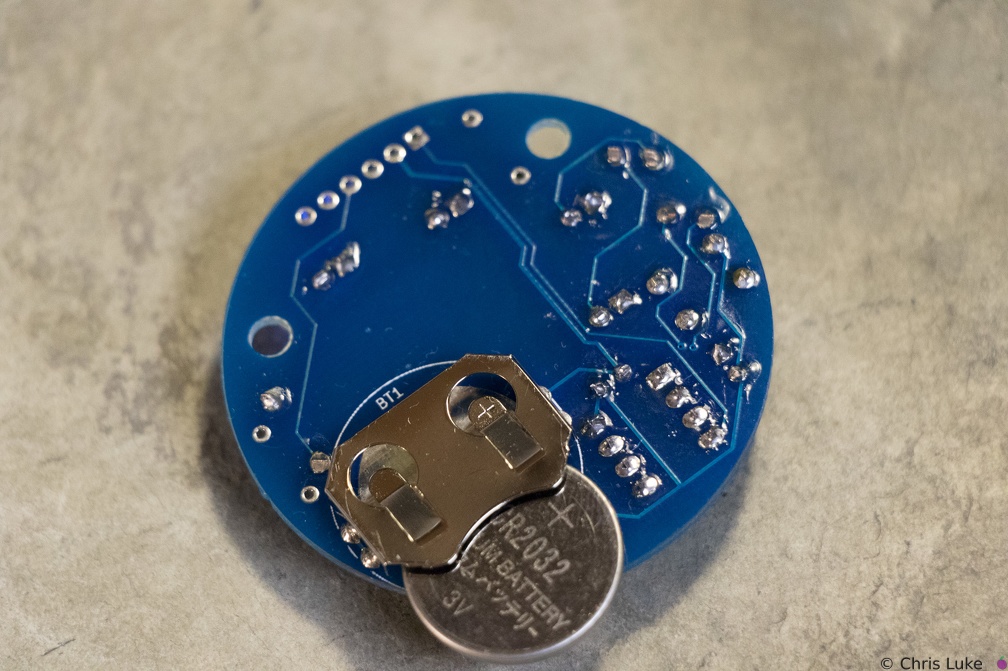

All the LEDs have been soldered. Notice that they all have the same orientation; the flat edge is to the left. Stockton STEM Badge battery

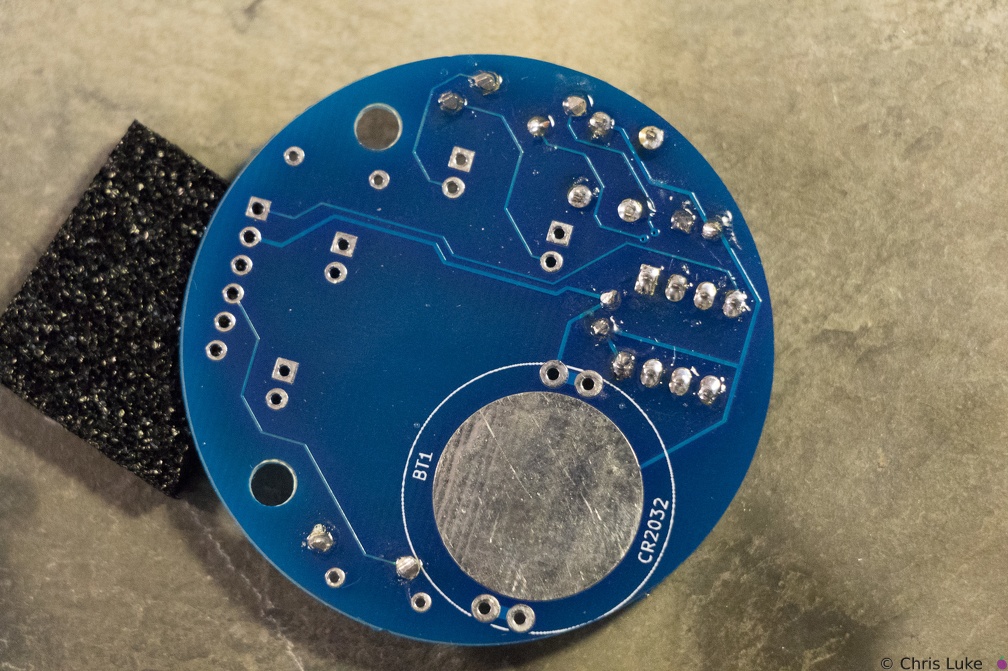

Stockton STEM Badge battery

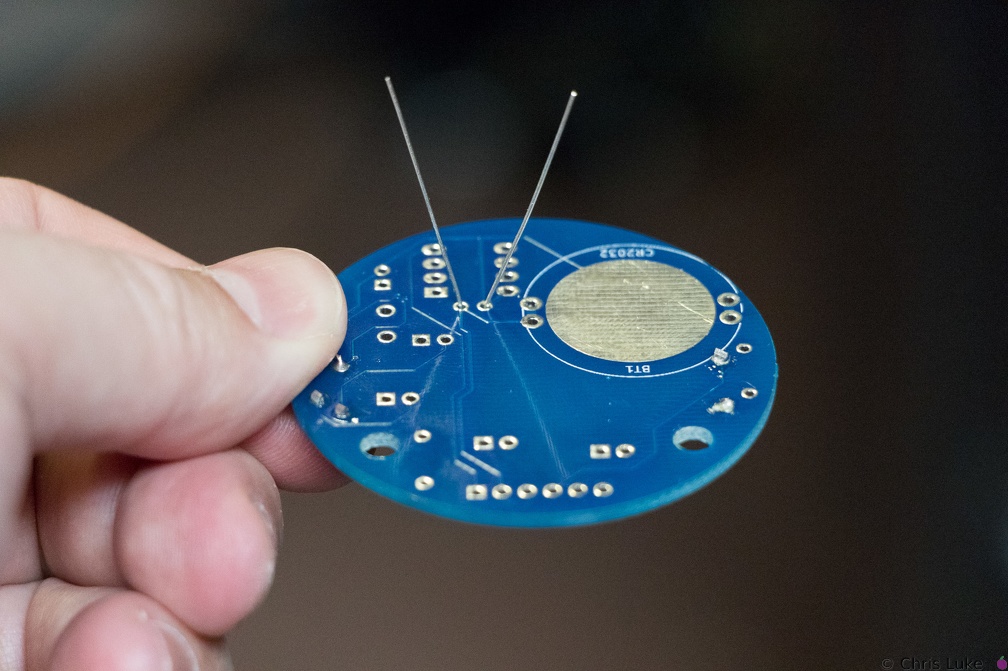

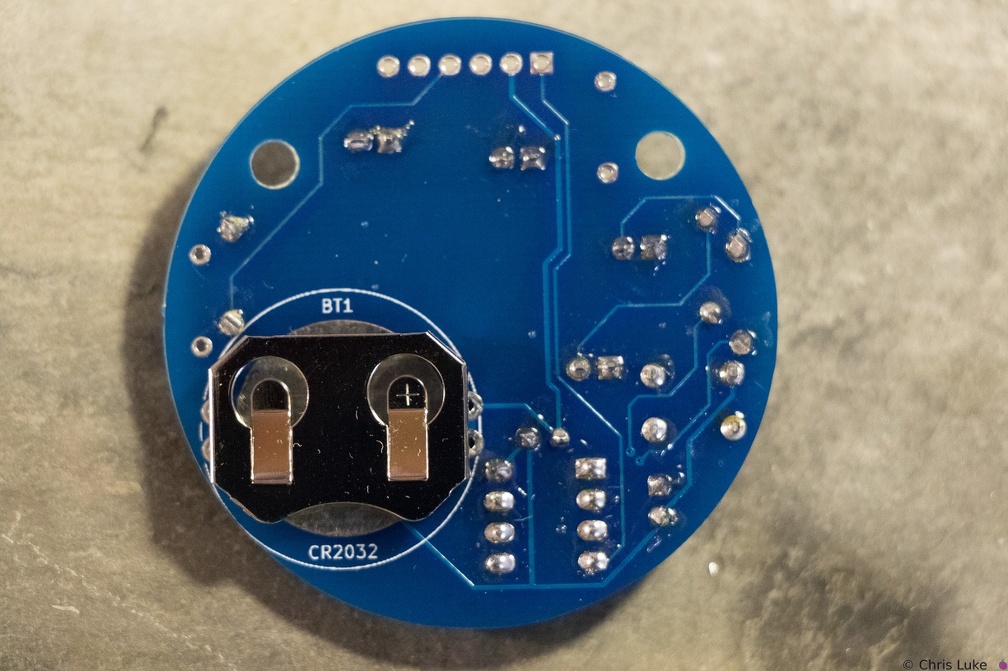

The battery holder is a simple metal cage that solders to the underside of the board. Stockton STEM Badge battery

Stockton STEM Badge battery

Note the orientation of the holder; reversing it will make it difficult to insert the battery later. Stockton STEM Badge battery

Stockton STEM Badge battery

It is possible for the holder to become hot during soldering; be careful when handling immediately after soldering. Stockton STEM Badge IC

Stockton STEM Badge IC

The IC pins need to be straight and line up with their receptacles in the socket. Stockton STEM Badge IC

Stockton STEM Badge IC

When inserting the IC, firm but controlled pressure is needed to avoid bending the pins. Stockton STEM Badge IC

Stockton STEM Badge IC

Make sure the IC is correctly aligned before pushing it in. Stockton STEM Badge IC

Stockton STEM Badge IC

Once pushed all the way in, the IC may sit above the socket, but it will be parallel to it. Stockton STEM Badge battery

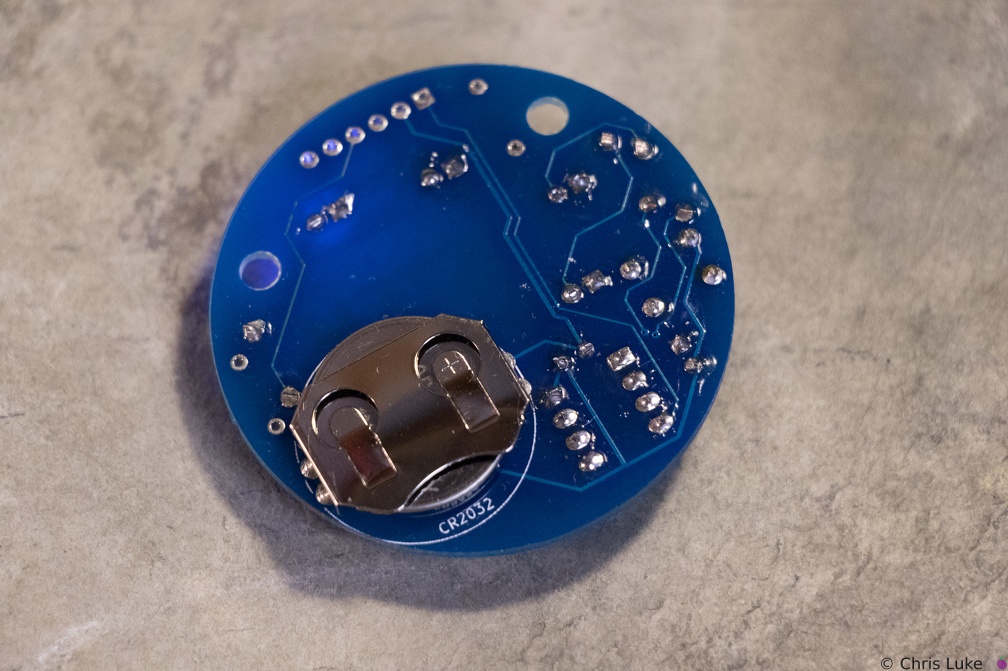

Stockton STEM Badge battery

The battery is a typical CR2032 button cell. Notice which side the "+" is on. Stockton STEM Badge battery

Stockton STEM Badge battery

Note the orientation of the battery. The "+" side contacts the battery holder. Stockton STEM Badge battery

Stockton STEM Badge battery

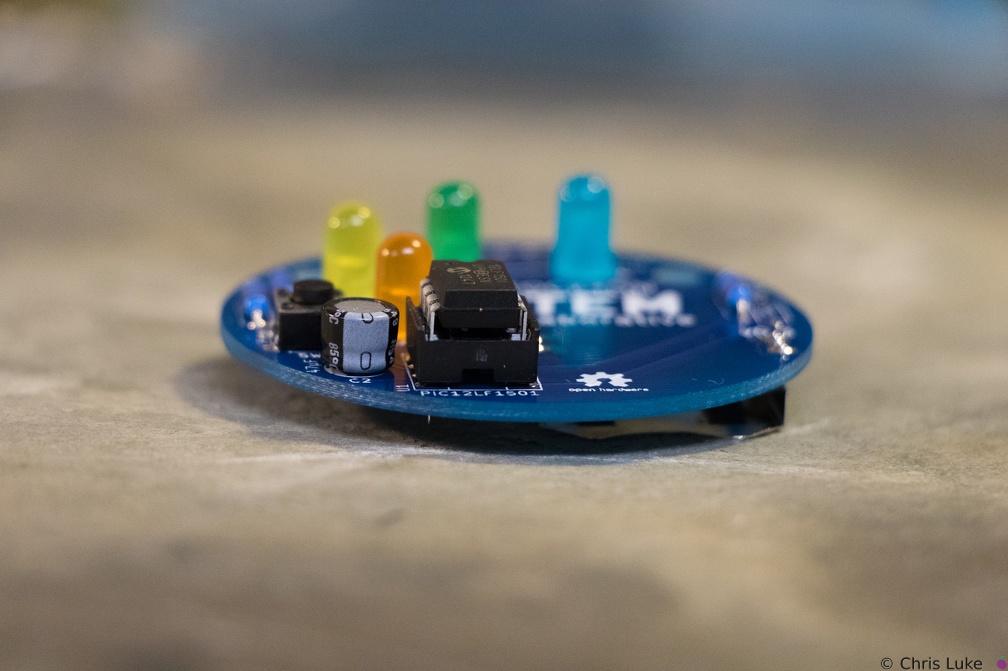

The battery should sit snugly under the holder. Stockton STEM Badge completed

Stockton STEM Badge completed

Press the button to start the lights! 3C2A6464

3C2A6464 3C2A6467

3C2A6467 3C2A6468

3C2A6468 3C2A6470

3C2A6470 3C2A6471

3C2A6471 3C2A6474

3C2A6474 3C2A6477

3C2A6477 3C2A6479

3C2A6479 3C2A6483

3C2A6483 3C2A6486

3C2A6486 3C2A6491

3C2A6491 3C2A6495

3C2A6495 3C2A6496

3C2A6496 3C2A6497

3C2A6497 3C2A6499

3C2A6499 3C2A6501

3C2A6501 3C2A6502

3C2A6502 3C2A6505

3C2A6505 3C2A6510

3C2A6510 3C2A6517

3C2A6517 3C2A6525

3C2A6525 3C2A6529

3C2A6529 3C2A6530

3C2A6530 3C2A6532

3C2A6532 3C2A6533

3C2A6533 3C2A6536

3C2A6536 3C2A6538

3C2A6538 3C2A6540

3C2A6540 3C2A6547

3C2A6547 3C2A6549

3C2A6549 3C2A6550

3C2A6550 3C2A6553

3C2A6553 3C2A6554

3C2A6554 3C2A6557

3C2A6557 3C2A6558

3C2A6558 3C2A6559

3C2A6559 3C2A6560

3C2A6560 3C2A6561

3C2A6561 3C2A6563

3C2A6563 3C2A6565

3C2A6565 3C2A6577

3C2A6577 3C2A6578

3C2A6578 3C2A6587

3C2A6587 3C2A6590

3C2A6590 3C2A6591

3C2A6591 3C2A6593

3C2A6593 3C2A6600

3C2A6600 3C2A6604

3C2A6604 3C2A6606

3C2A6606 3C2A6607

3C2A6607 3C2A6610

3C2A6610 3C2A6614

3C2A6614 Mathematical Bridge

Mathematical Bridge 3C2A6623

3C2A6623 3C2A6625

3C2A6625 3C2A6627

3C2A6627 3C2A6628

3C2A6628 3C2A6629

3C2A6629 3C2A6634

3C2A6634 3C2A6635

3C2A6635 3C2A6641

3C2A6641 3C2A6642

3C2A6642 3C2A6646

3C2A6646 3C2A6648

3C2A6648 3C2A6649

3C2A6649 3C2A6651

3C2A6651 3C2A6653

3C2A6653 3C2A6662

3C2A6662 3C2A6669

3C2A6669 3C2A6680

3C2A6680 3C2A6684

3C2A6684 3C2A6698

3C2A6698 Piper vs. Apollo

Piper vs. Apollo 3C2A6714

3C2A6714 3C2A6716

3C2A6716 3C2A6717

3C2A6717 3C2A6719

3C2A6719 3C2A6735

3C2A6735 3C2A6737

3C2A6737 3C2A6745

3C2A6745 3C2A6747

3C2A6747 3C2A6751

3C2A6751 3C2A6752

3C2A6752 3C2A6754

3C2A6754 3C2A6767

3C2A6767 3C2A6769

3C2A6769 3C2A6771

3C2A6771 3C2A6775

3C2A6775 3C2A6777

3C2A6777 3C2A6785

3C2A6785 3C2A6786

3C2A6786 3C2A6791

3C2A6791 3C2A6795

3C2A6795 3C2A6797

3C2A6797 3C2A6803

3C2A6803 3C2A6806

3C2A6806 3C2A6817

3C2A6817 3C2A6818

3C2A6818 3C2A6826

3C2A6826 3C2A6848

3C2A6848 3C2A6852

3C2A6852 3C2A6853

3C2A6853 3C2A6857

3C2A6857 3C2A6861

3C2A6861 3C2A6864

3C2A6864 3C2A6907

3C2A6907 3C2A6911

3C2A6911 3C2A6916

3C2A6916 3C2A6996

3C2A6996 3C2A7016

3C2A7016 3C2A7021

3C2A7021 3C2A7024

3C2A7024 3C2A7025

3C2A7025 3C2A7026

3C2A7026 3C2A7031

3C2A7031 3C2A7034

3C2A7034 3C2A7040

3C2A7040 3C2A7080

3C2A7080 3C2A7100

3C2A7100 3C2A7119

3C2A7119 3C2A7120

3C2A7120 3C2A7141

3C2A7141 3C2A7153

3C2A7153 3C2A7158

3C2A7158 3C2A7187

3C2A7187 3C2A7197

3C2A7197 3C2A7202

3C2A7202 3C2A7218

3C2A7218 3C2A7220

3C2A7220 3C2A7224

3C2A7224 3C2A7226

3C2A7226 3C2A7232

3C2A7232 3C2A7236

3C2A7236 3C2A7237

3C2A7237 3C2A7241

3C2A7241 3C2A7242

3C2A7242 3C2A7244

3C2A7244 3C2A7248

3C2A7248 3C2A7252

3C2A7252 3C2A7259

3C2A7259 3C2A7263

3C2A7263 3C2A7272

3C2A7272 3C2A7277

3C2A7277 3C2A7283

3C2A7283 3C2A7306

3C2A7306 3C2A7326

3C2A7326 3C2A7338

3C2A7338 3C2A7342

3C2A7342 3C2A7345

3C2A7345 3C2A7351

3C2A7351 3C2A7364

3C2A7364 3C2A7365

3C2A7365 3C2A7374

3C2A7374 3C2A7385

3C2A7385 3C2A7395

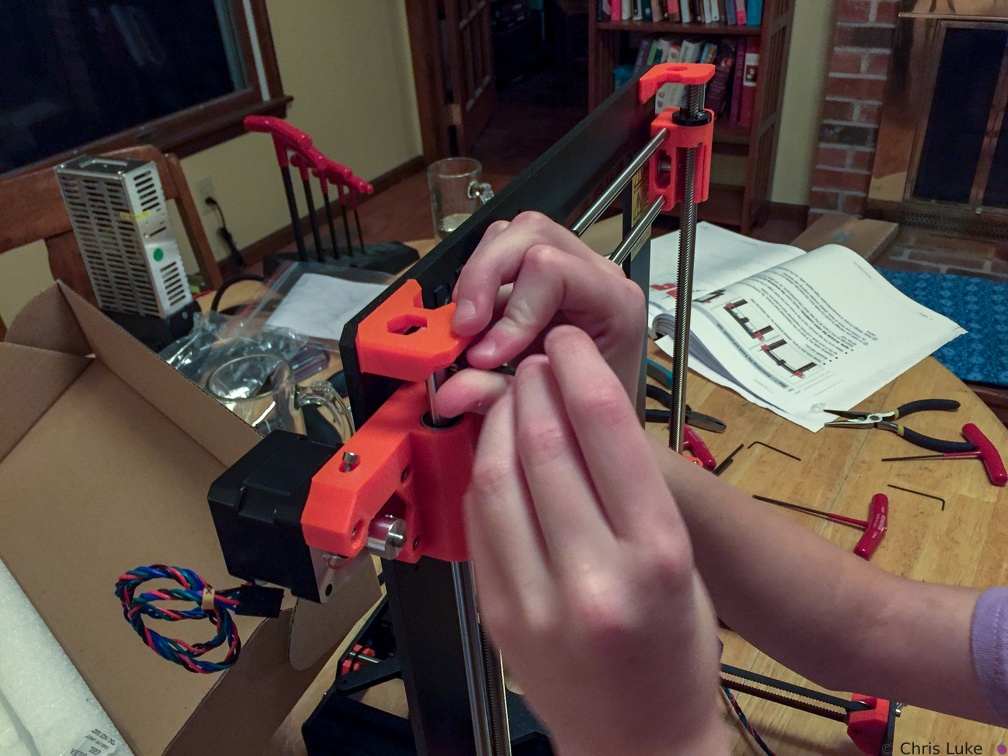

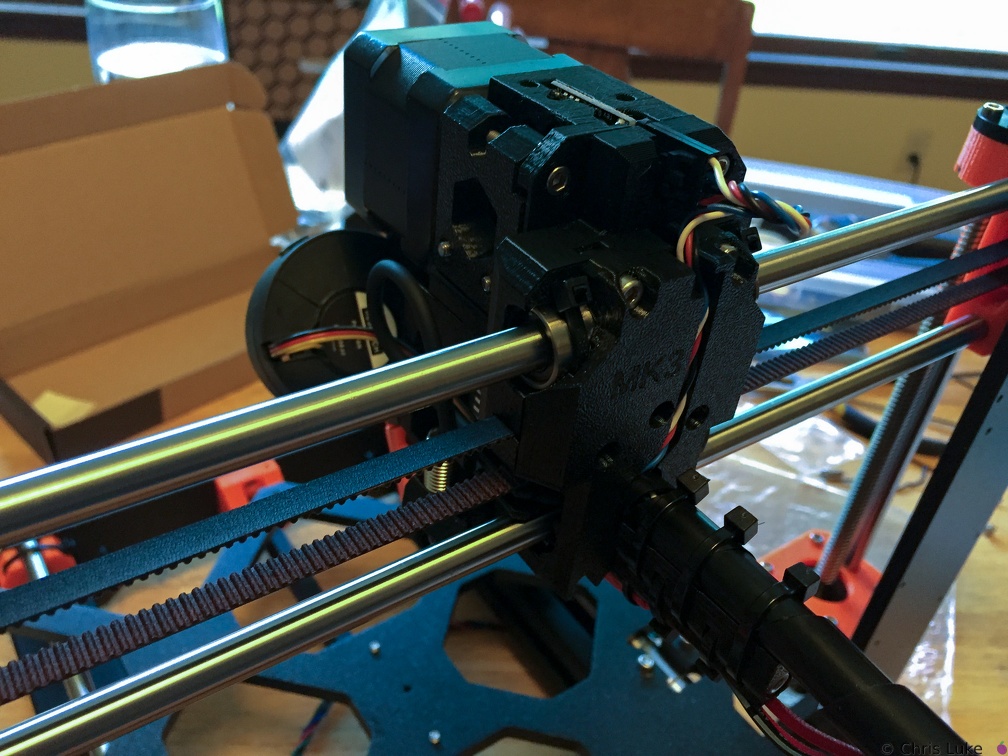

3C2A7395 Y-axle idler pulley

Y-axle idler pulley Testing the slide of the bed

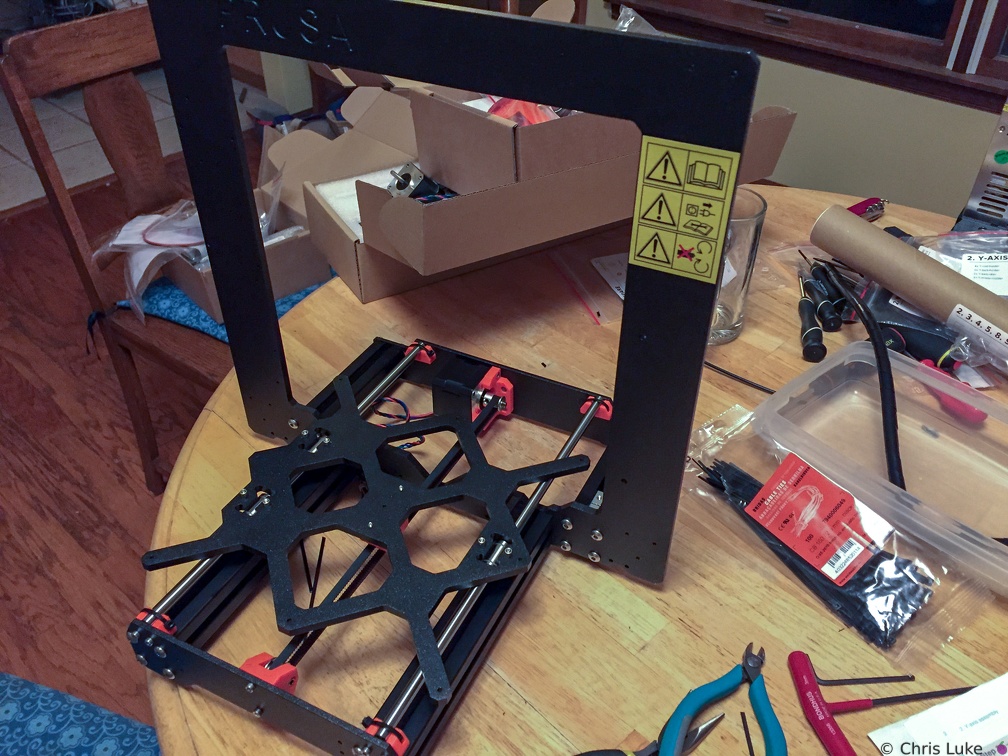

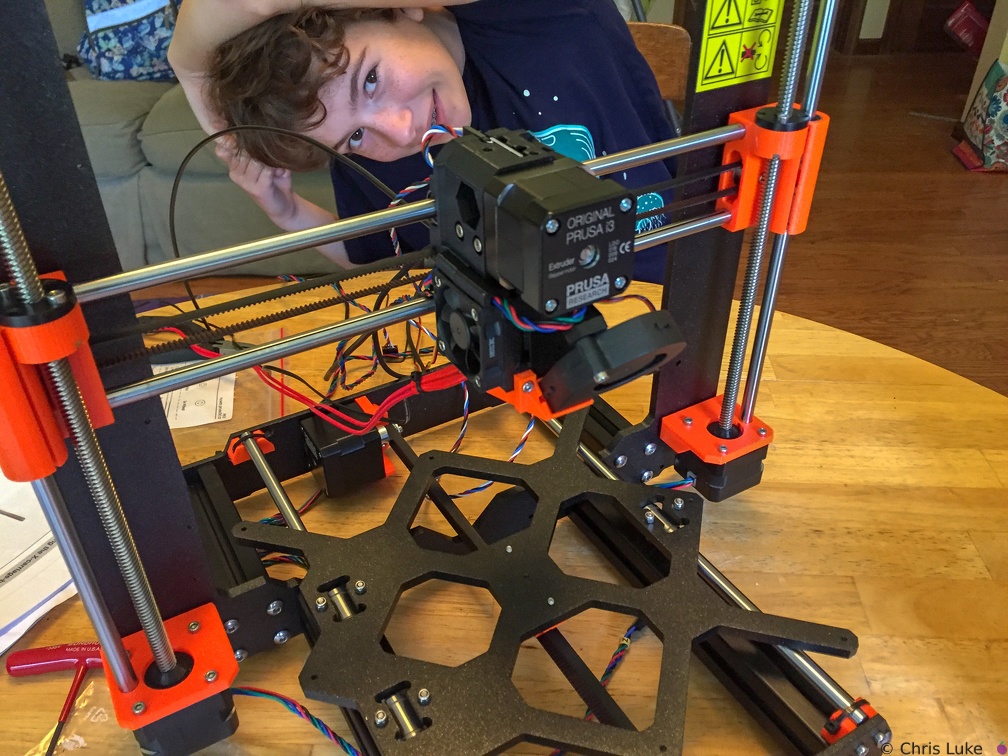

Testing the slide of the bed Taking shape

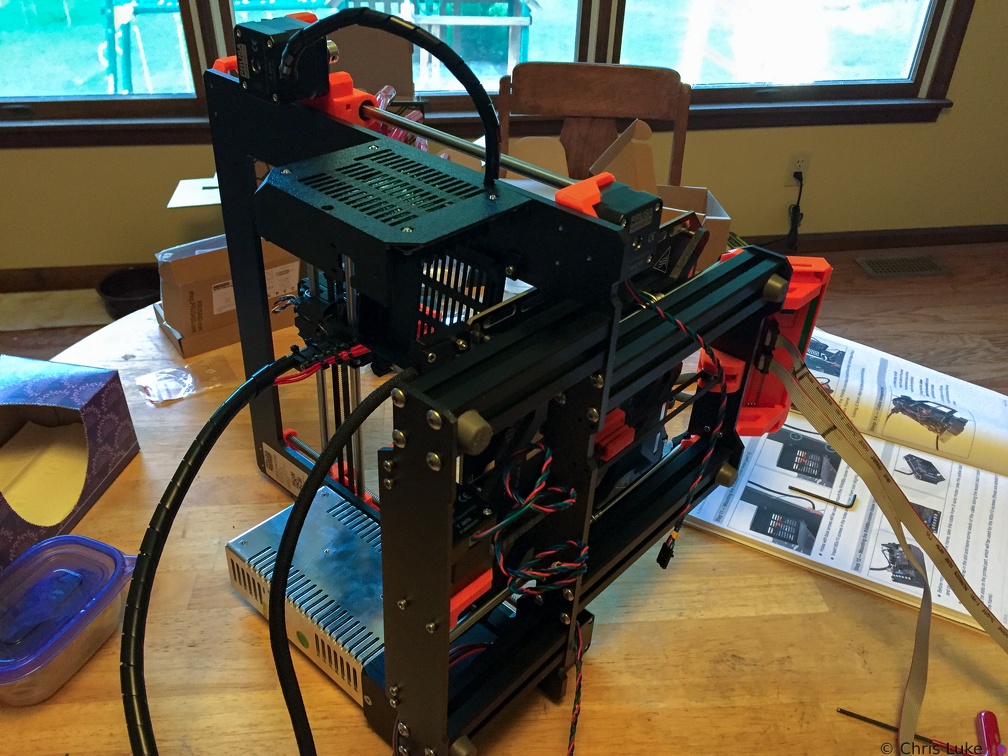

Taking shape Z-axis motor mounts

Z-axis motor mounts Z-axis motor mounts

Z-axis motor mounts X and Z axis

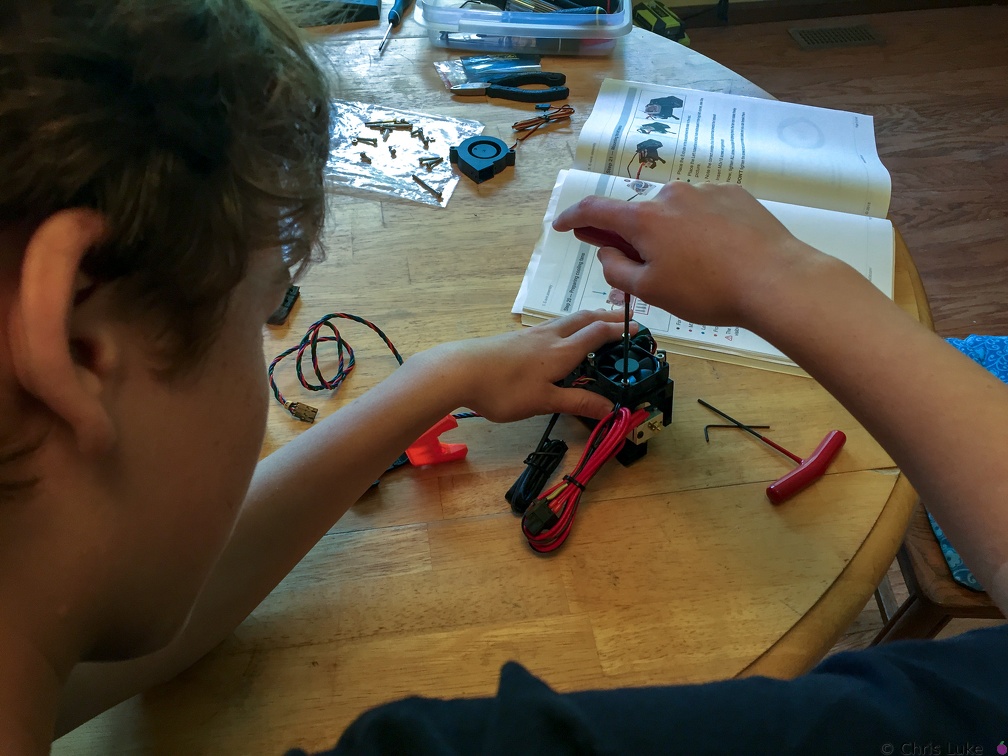

X and Z axis Hotend fan

Hotend fan Print head cables

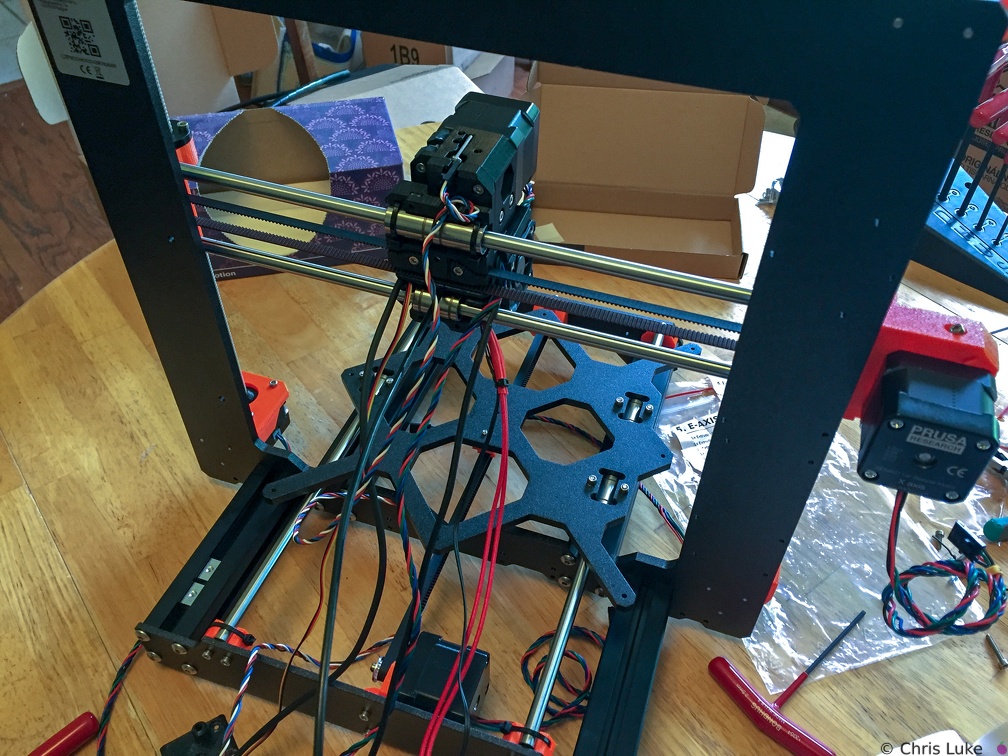

Print head cables Cables everywhere

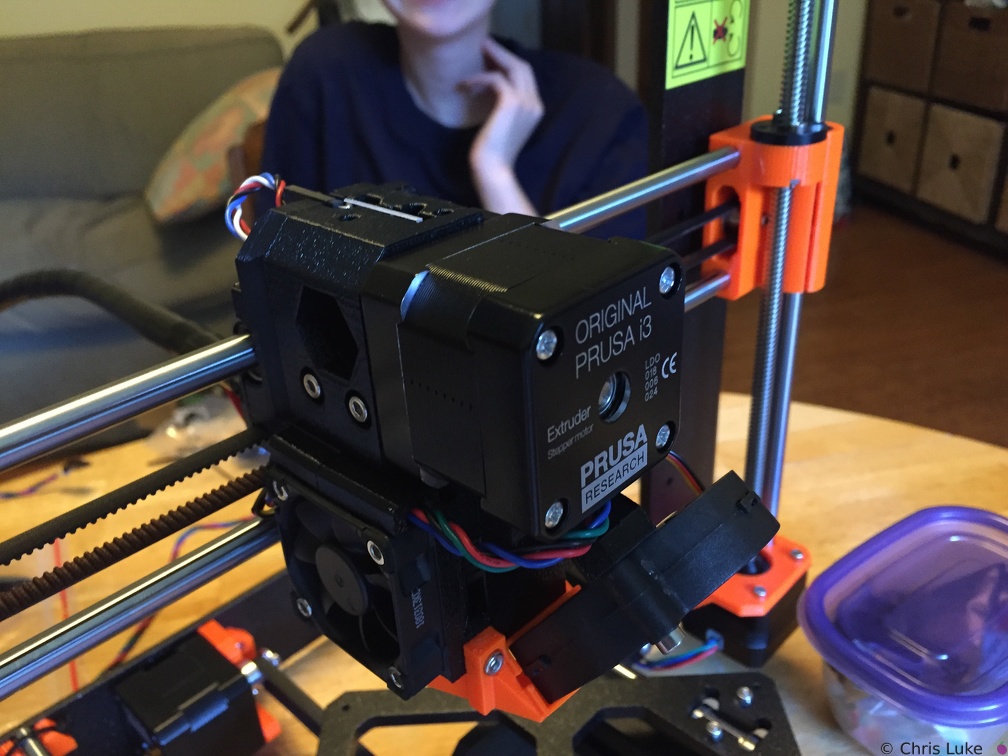

Cables everywhere Printhead rear

Printhead rear Printhead front

Printhead front The cables have to go somewhere

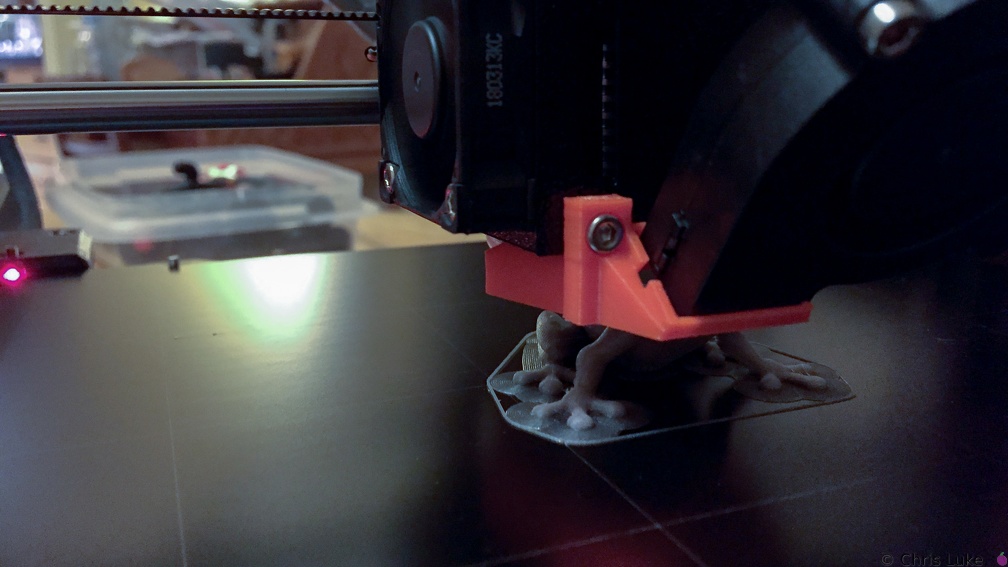

The cables have to go somewhere First print in progress

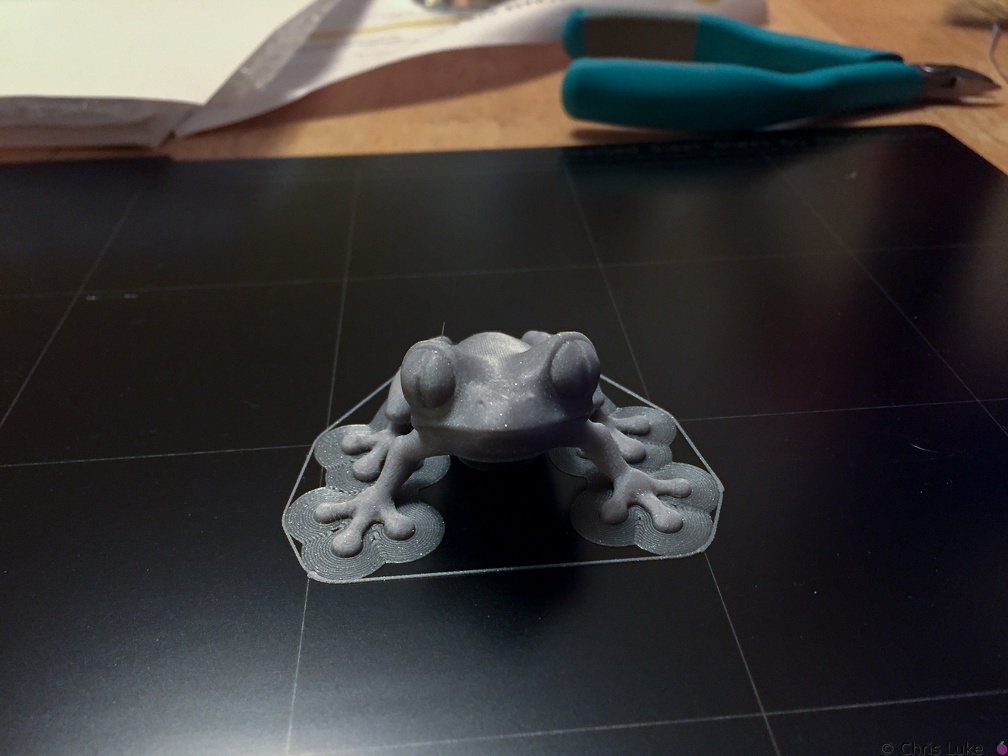

First print in progress Treefrog

Treefrog Baby Groot

Baby Groot